article

Ball mill upgrade cuts energy consumption by 25%

Upgrading an existing ball mill circuit with hydraulic roller presses and TRIBOMAX® wear surfaces achieved a 127% increase in production, at the same time as lowering power consumption by 25%, at JK Cement’s Mangrol cement plant.

A key principle of industrial sustainability is the need to do more with less. At a cement plant, there are a number of pathways to achieve this. But one of the most important is the adoption of technology that reduces energy consumption, while preserving – or even increasing – production: the addition of a hydraulic roller press (HRP) to a ball mill circuit is a proven example of what can be achieved in this regard.

When the HRP is fitted with an innovative, long-lasting wear solution, such as FLSmidth Cement's TRIBOMAX wear surface , production is further enhanced, while higher durability and resistance to wear and damage means less maintenance and risk of downtime. This not only results in lower operational costs, it also reduces wear material consumption – meaning you grind more between repair or replacement of the wear surface – and improves the overall availability of the grinding circuit.

Case study: JK Cement Mangrol and Nimbahera cement plants

Part of Indian industrial conglomerate, the JK organisation, JK Cement is one of the country’s leading cement manufacturers, with 14.7 million tpa of grey and 1.2 million tpa of white cement production capacity. When it came to upgrade its production facilities at its Mangrol and Nimbahera cement plants, the company was looking for a solution that would not only allow it to expand production capacity, but also to do so in a way that ensured high reliability and improved sustainability of grinding operations.

After undertaking a techno-commercial evaluation of the available options, the company decided to add a HRP for semi-finish grinding of clinker to its existing ball mill circuits. This option is not only more cost effective than replacing the complete grinding circuit but is also a more sustainable and materials-efficient approach that makes the most of the ball mills, while delivering the needed improvements in production and energy consumption.

To realize the upgrade, JK Cement turned to its technology partner of almost 50 years, FLSmidth Cement. The Danish engineering company, which this year is celebrating its 140th anniversary, has installed more than 115 HRPs since 1986. These flexible pieces of equipment are suitable for both new installations and, as at JK Cement, upgrades of conventional ball mill circuits, where they can more than double production capacity and reduce specific energy consumption by 30%.

This combination of economy and sustainability makes HRPs a competitive, cost-effective step on the journey to low-emission cement production – a key aim of FLSmidth Cement's Mission Zero strategy.

The results at JK Cement proved again the benefits of HRP 's in an existing ball mill circuit. At the Mangrol plant, for example, production increased 127% following HRP installation, while specific power consumption fell by more than 25% (Table 1).

Table 1. Operating parameters JK Mangrol-Upgrade

*Capacity, fineness and SPC values are corrected in line with the PGT values of feed mix and Blaine.

Compounding the benefits: FLSmidth Cement TRIBOMAX wear surface

Both Mangrol and Nimbahera plants also opted to equip their HRPs with FLSmidth Cement TRIBOMAX wear surfaces. Normal hard facing is susceptible to premature failure, when the hard surface is overloaded by tramp metal or oversize materials. TRIBOMAX wear surfaces solve this problem.

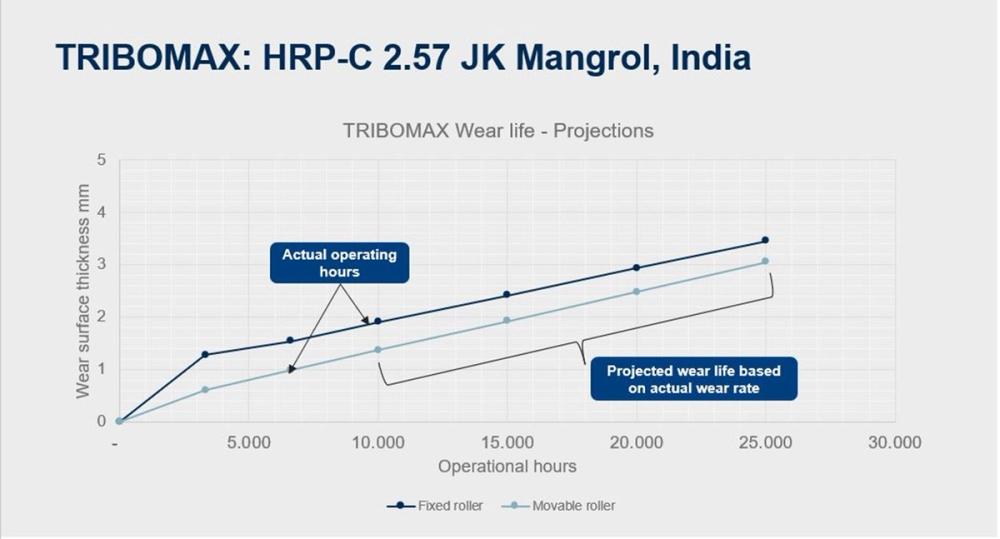

Taking its name from tribology, the science and engineering of interactive surfaces in relative motion, the TRIBOMAX wear solution is extremely tough, designed specifically to withstand the demanding conditions of grinding clinker, slag and raw meal. Its high resistance to wear and surface damage – with a guaranteed wear of life of 25,000 hours and zero maintenance requirements on the wear surface – prolongs roller lifetime significantly, delivering high roller durability, and thus high availability of the HRP system.

The TRIBOMAX design is based on a unique plasma transfer arc welding deposit technology. Compared to traditional hardfacing, this lays down a purer wear surface, in terms of metallurgical composition, with fewer imperfections, such as cracks and porosities. Meanwhile, the TRIBOMAX surface’s microstructure formulations achieve high surface friction (a key factor in improving grinding efficiency) and an autogenous wear layer (further enhancing roller durability).

At JK Cement’s Mangrol plant, the performance of the TRIBOMAX wear surface has been “exceptional”, according to Avanish Karrahe, Global Product Manager – Grinding at FLSmidth Cement.

“Our Tribomax wear surface has achieved reduced operational cost, increased wear life and availability of the system. We have also observed in almost all Tribomax installations, an improvement in production enhancement by around 5%, which is directly attributable to the in-built roughness of Tribomax wear surface.”

More importantly, the customer has been similarly impresses by the performance of the TRIBOMAX wear solution.

S.K. RATHORE\nManufacturing Head, JK Cement Ltd.

“The durability, flexibility and ZERO maintenance of the wear surface makes it a highly cost-effective solution with a low total cost of ownership. Tribomax is also a very sustainable wear surface solution for any roller press plant with focus towards increase in machine availability and reducing the maintenance time & cost.”

Conclusion: the sustainability challenge… and opportunity

The imperative to reduce carbon emissions in cement manufacture is now widely recognized and becoming an everyday concern of cement plant operators around the world. At the same time, cement production must remain cost competitive within local market conditions. Solutions that combine economic returns and enhanced competitiveness with sustainability wins – such as lower energy and materials consumption – are therefore vital for the industry’s progress to zero emission cement.

FLSmidth Cement is committed to supporting the industry on this sustainability journey, providing services and solutions that support the cement industry meet both financial and environmental goals. In this way, the company – alongside its customers and other partners – is working to build a truly sustainable cement industry.

Key benefits of the TRIBOMAX wear solution:

- Longer wear life than traditional hardfacing solutions - more than 25,000 hours

- One wear solution for cement, slag and raw mix

- Higher resistance towards tramp material than existing hardfacing solutions

- Low maintenance and cost-effective

- Reduced risk of failure

- Low total cost of ownership