The highest performing mechanised bag palletizer on the market

What we offer

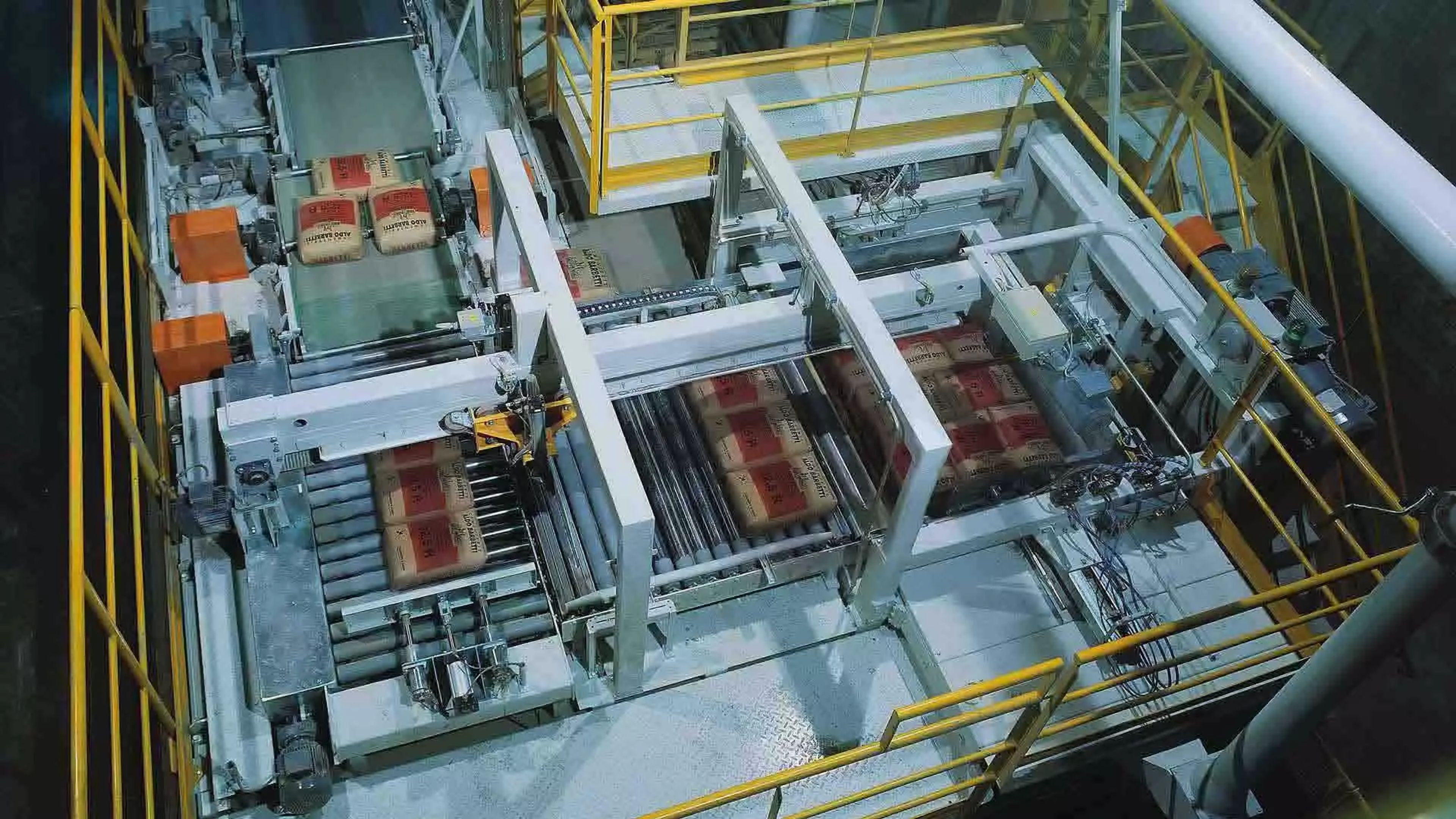

Complete bag palletizing system for capacities up to 6000 bags/hour

Packing plants have to handle a range of bag sizes, materials and capacities. If you want to avoid bottlenecks, the palletizing system must keep up with the packing line. But it’s not just about high capacities. Modes of transport are also different from place to place, and your automatic bag stacking configuration must take this into account. Slip sheet, stretch hood, a wooden pallet base or no pallet at all – your system needs to be flexible enough to meet your needs, even if those needs change. We have 40 years of experience in the development of palletizers through the Ventomatic® brand. Starting from the first SPV-type suction pad palletizers to the well-established M series, we have always aimed at bringing innovative design and technology to the market. The modular POLIMAT® series palletizer is the result of this continuous research. Bag palletizers are completely prewired with fast connection plugs, preassembled and pretested in the manufacturing workshop, making them simple to install and commission. We also use standard parts across our range, to minimise delivery time. A full range of configurations is available, including slip sheet, stretch hood and palletless automatic bag stacking. You asked for increased palletizing speed with absolute accuracy. We’ve delivered this by using advanced controls such as brushless motors and closed loop inverters. And with the introduction of our innovative operator machine interface (HMI), we’ve made it easy to set the pallet configuration and parameters. You also get more support for diagnostics, troubleshooting and recording production statistics so you can really get the most from your machine. State-of-the-art electronic components ensure high reliability. While the flexible design allows you to choose the best configuration for you – full automatic regulation for multiple bags size, various stack height, a range of full pallet weights, etc. A Fieldbus control network for all sensors can be installed on the equipment if desired. And of course we offer a wide range of auxiliary equipment to fit the layout requirements according to available space and preferred method of dispatch.

True flexibility: palletizing and automatic bag stacking to suit you

Capacity up to 6000 bags per hour

The VENTOMATIC® POLIMAT® can reach high capacities, depending on your bag dimension, pattern configuration and the number of layers to be stacked. The maximum total load for each stack is 2.75 t.

Suitable for different bag types and sizes

Automated adjustment and regulation for multiple bag size/layer configurations is easy thanks to the centralised operator panel, which memorises your preferred stacking parameters.

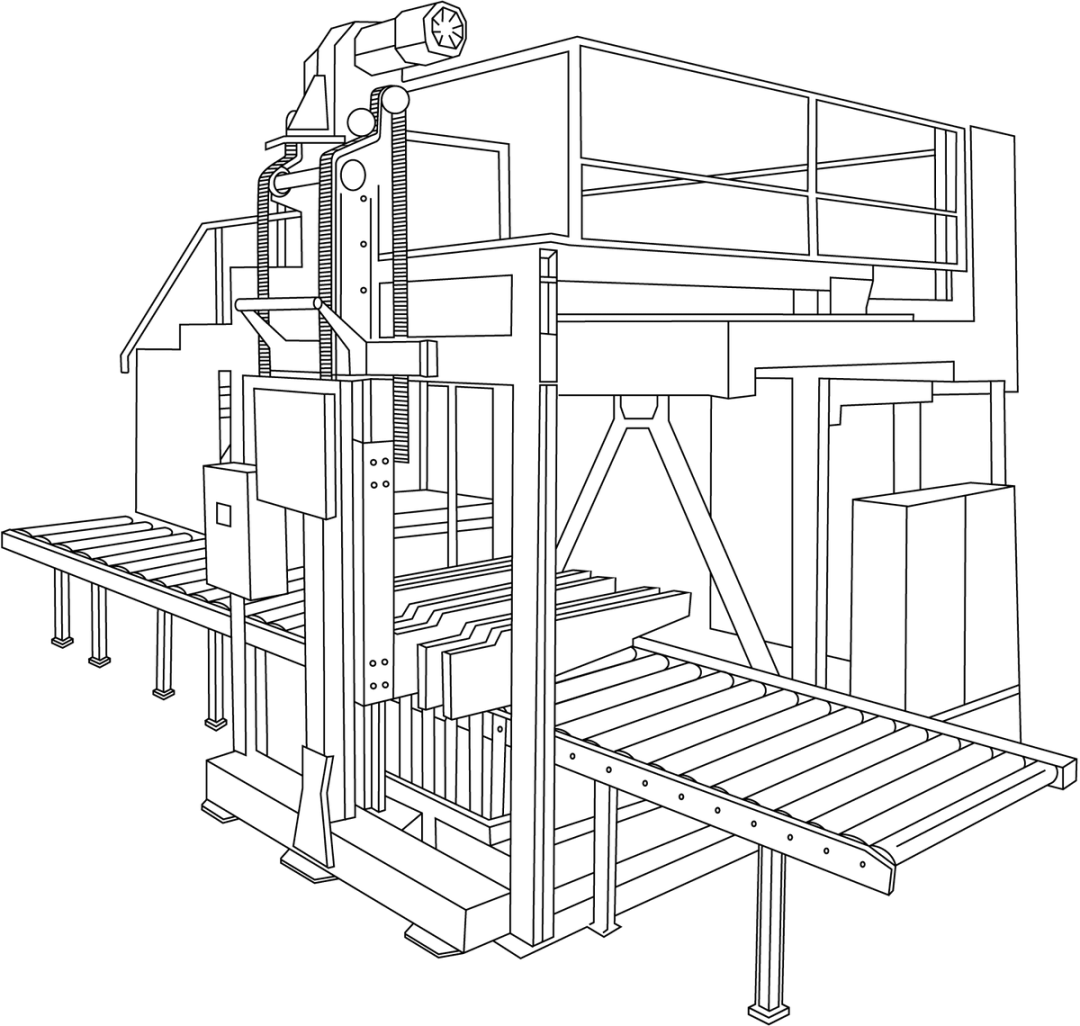

Modular design and IPC advanced control system and Fieldbus technology

Keep an eye on your process with real time monitoring, with troubleshooting messages and data transmission to DCS via communication protocol (profibus, ethernet or others).

Full range of options and accessories available

What’s your preference? The VENTOMATIC® POLIMAT® is suitable for standard wooden or plastic pallets, plastic slip sheet, carton board, palletless line, stretch hood or sling bags.

Easy and cost-effective maintenance

Thanks to the modular concept, including prewired execution with fast clamp connection, and the fact that there are no pneumatics or hydraulics, only electrical controls and actuators, maintenance activities are easy and cost effective. Critical spares are available on stock and delivered on demand.

Simple installation, easy operation: the VENTOMATIC® POLIMAT® bag palletizing systems

Product range

The range of VENTOMATIC® palletizing lines is designed to suit every kind of application. The EVO series are divided into three groups: small, medium and high capacity: Low capacity models up to 2500 bags/h are suitable for handling paper, plastic and woven PP bags of different weights and sizes. Medium capacity models up to 3600 bags/h are suitable for paper, plastic and woven PP bags of different weights and sizes. High capacity models up to 6000 bags/h models are suitable for paper, plastic and woven PP bags of different weights and sizes.

Flexibility

A wide range of bags/layer patterns can be accommodated, covering all conventional bag sizes and pallet dimensions, with stack stability always ensured.

Electrical board and operator control panel

The HMI is easy to use with a 5.7 in. touch screen for simple scrolling. Setting the parameters for variable bag and pallet dimensions is quick and easy. Machine alarms, message display and historical log of alarms helps you keep on top of your system. You also benefit from: Diagnostic data and troubleshooting support Machine data with local back-up Easy interface with a supervision system for data exchange Fieldbus control network Depending on your needs, we can integrate the palletizing lines with several additional technologies in order to optimise the handling system and/or the mode of dispatch.How do you prefer to secure your stack? We cater for a range of solutions, including: Stretch hood for stack protection and stability; Palletless for waterproof packaging of the load, available in different configurations according to the stacking capacity; Hot process (thermal-shrinking film with electrical or gas heating according to required capacity); and Cold process (stretch hood film).

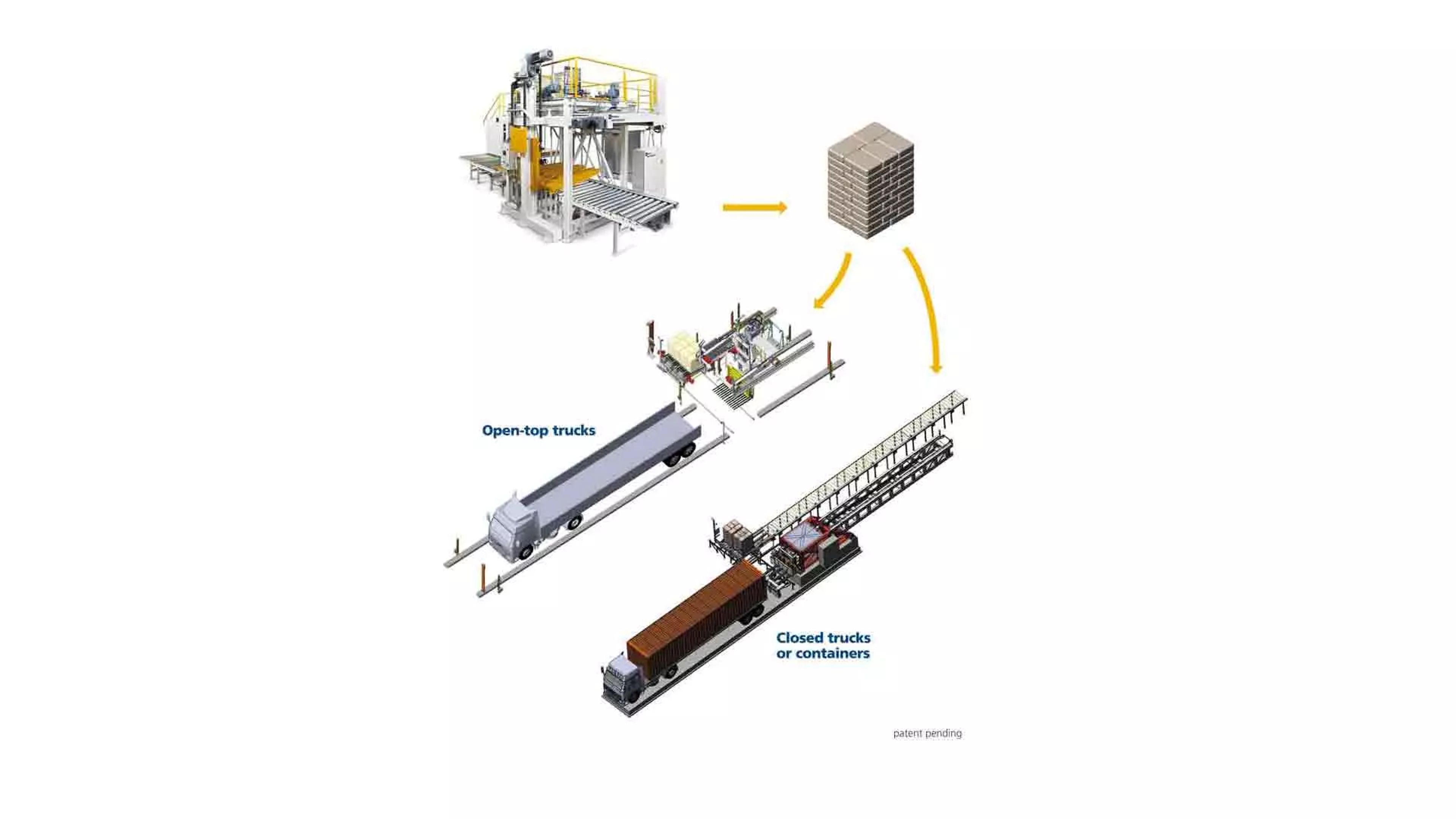

Complete mechanised logistics solution

The VENTOMATIC® POLIMAT® is designed for easy interface with the VENTOMATIC® Flying Fork-Lift FFL and VENTOMATIC® FFL-4C automatic truck loader for direct loading on open trucks, closed trucks or standard containers. With this system, the stacks are placed directly onto the trucks without the need for manual or fork-lift handling. It’s safer for operators – and kinder on the stacks. You can choose to connect the palletizing line directly, or store the stacks first and retrieve them later.