Highly accurate bag applicators state-of-the-art empty bag handling

What we offer

High capacity packing plants need automated empty bag applicators

Modern packing plants can deliver very high capacities – but only if bag applicators are mechanised. Manual bag placing simply can’t give you the high throughput – and accuracy – that your operation needs. The Ventomatic® INFILROT® range of empty bag applicators removes the need for manual operation, thanks to state-of-the-art robotics

Mechanical arm or shooting bags?

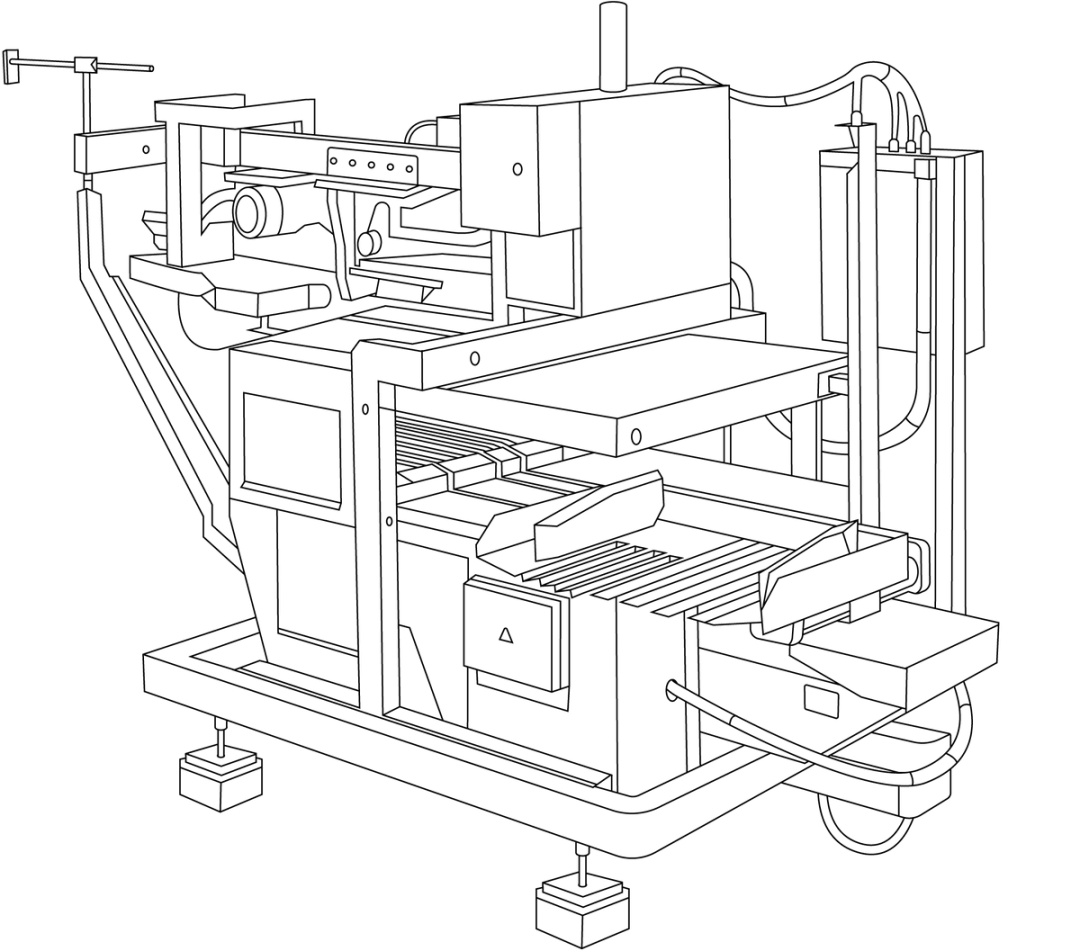

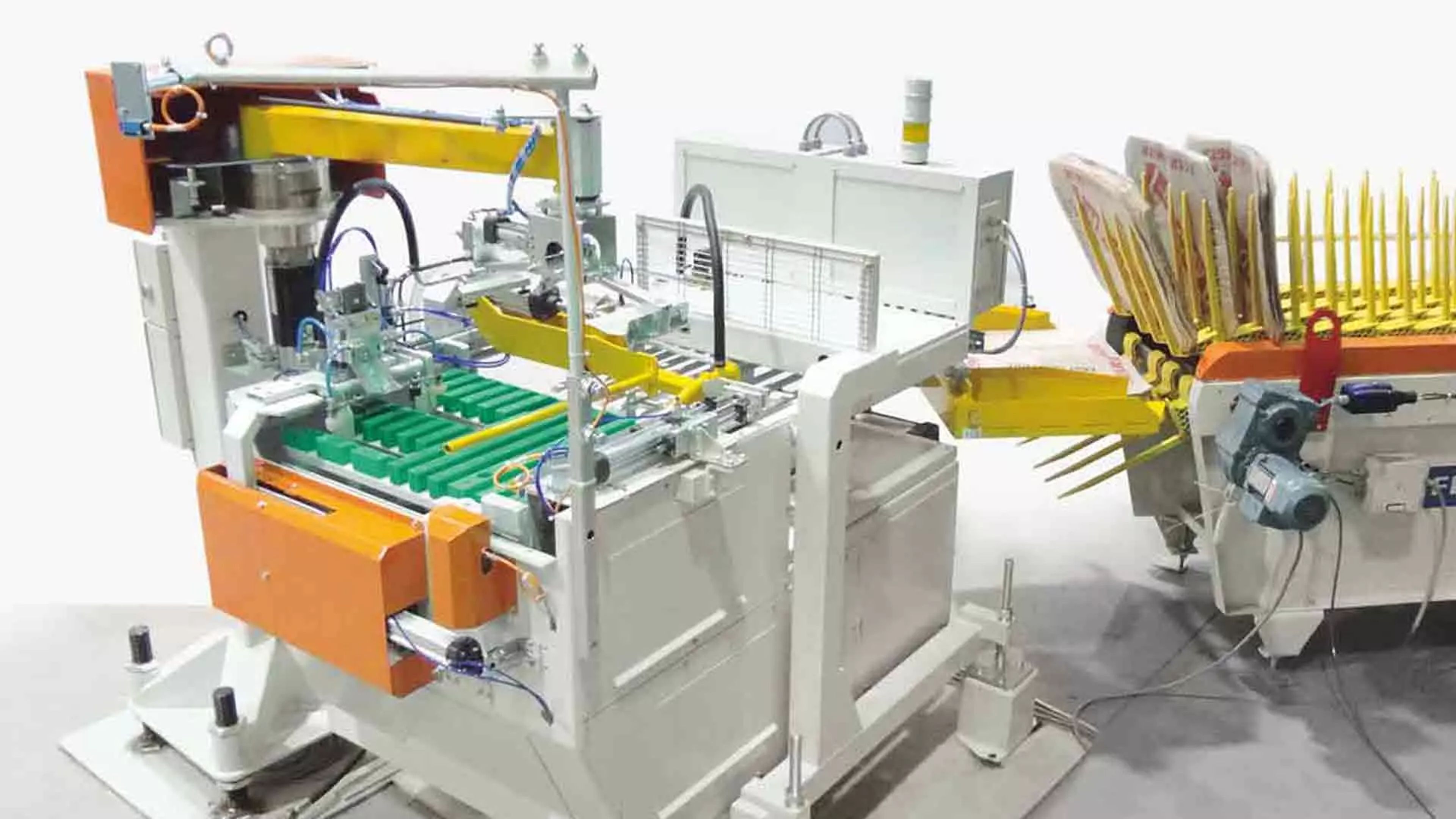

At the heart of empty bag handling is the automatic bag applicator designed for handling both glued and stitched bags manufactured in paper, plastic, woven polypropylene or other similar materials. Different applications require different solutions, and we are the only supplier to offer two distinct design concepts: - Mechanical arm type (INFILROT® BU range) - Shooting type (INFILROT® Z range) The choice depends on several factors such as: capacity, packer characteristics, bag dimensions, bag quality, environmental conditions, etc.

High reliability empty bag placing - at rates over 5000 bags/h

High capacity

Empty bag handling has to match the capacity of modern rotary packers and the demand of high-productivity packing lines. Our INFILROT® automatic bag applicator can achieve capacities over 5000 bags per hour. We can help you choose from mechanical or shooting bag technology, depending on your bag characteristics, material, manufacturing and required capacity.

Suitable for different bag characteristics

For glued valve or stitched valve bags made of paper, PP or HDPE, opt for the INFILROT® BU mechanical robotic arm concept with electronic axis control. • Capacity up to 3000 bags/h and reliability not less than 99,5%; • High flexibility for bags manufactured with different materials; • Low sensitivity to bag manufacturing quality; • Suitable for different bag dimensions with automatic adjustments; • HMI system for recipes, timers, parameters and manual/automatic controls; • Cabinet to control the automatic cycle and the automatic calibration and synchronisation with rotary packer. For very high capacities, handling only glued valve bags made from paper or WPP, choose the INFILROT® Z shooting type concept. • Capacity up to 5000 bags/h and reliability not less than 99.5%; • Suitable for different bag dimensions with automatic adjustments; • HMI system for recipes, timers, parameters and manual/automatic controls; • Cabinet to control the automatic cycle and the automatic calibration and synchronisation with rotary packer.

Different bag storage and feeding systems

Regardless of which model you choose, all bag applicators can be interlocked with empty bag storage and feeding solutions. NORIAMAT™ empty bags storage has a stock capacity up to 1600 bags and available with 3 or 6 m length. The new design grants more stability to the bag bundle and maintenance is easy with the new plastic forks. VENTOFEED™ empty bag de-palletizer is a completely automatic de-palletiser for empty bag bundles compatible with several bag sizes and pattern layers. Suitable for operating: • With any type of automatic bag applicator with 8-hour shift system autonomy; • With strapped bag bundles palletized as usual; • On all the bundles of each pallet including the bottom layer: • An empty pallet stacker can also be supplied if required.

A valve bag applicator that meets your demand for high productivity

The first Ventomatic® mechanical arm type was developed in 1976 based on the experience gained from the bag applicators we made for in-line packers. Afterwards, the INFILROT® Z shooting type technology was implemented and developed. The design of the Z 40 and Z 60 models is based on a cross-pollination of the best components of the INFILROT® BU and ZIPPER models. These applicators can meet the increasing output of rotary packers– the proof is in their many successful references in packing plants around the world. All bag applicators and empty bag handling are based on IPC technology for command and control of the functions. Online monitoring, calibration and troubleshooting is available via internet connection. And of course, you have the full support of FLSmidth engineers, wherever you are in the world.