Protect your kiln with our ECS/CemScanner™ kiln shell monitoring system

_Kiln_Shell_Monitoring_System.png?w=1080&q=80&auto=format)

What we offer

An advanced kiln shell monitoring system

We’ve got more than 40 years experience in helping our customers to intelligently measure and monitor the performance of their kilns. Over that time, we’ve used customer feedback and the expertise of our engineers to continually improve on our offering, which is reflected in the reliability and performance of ECS/CemScanner™ today.

What is it?

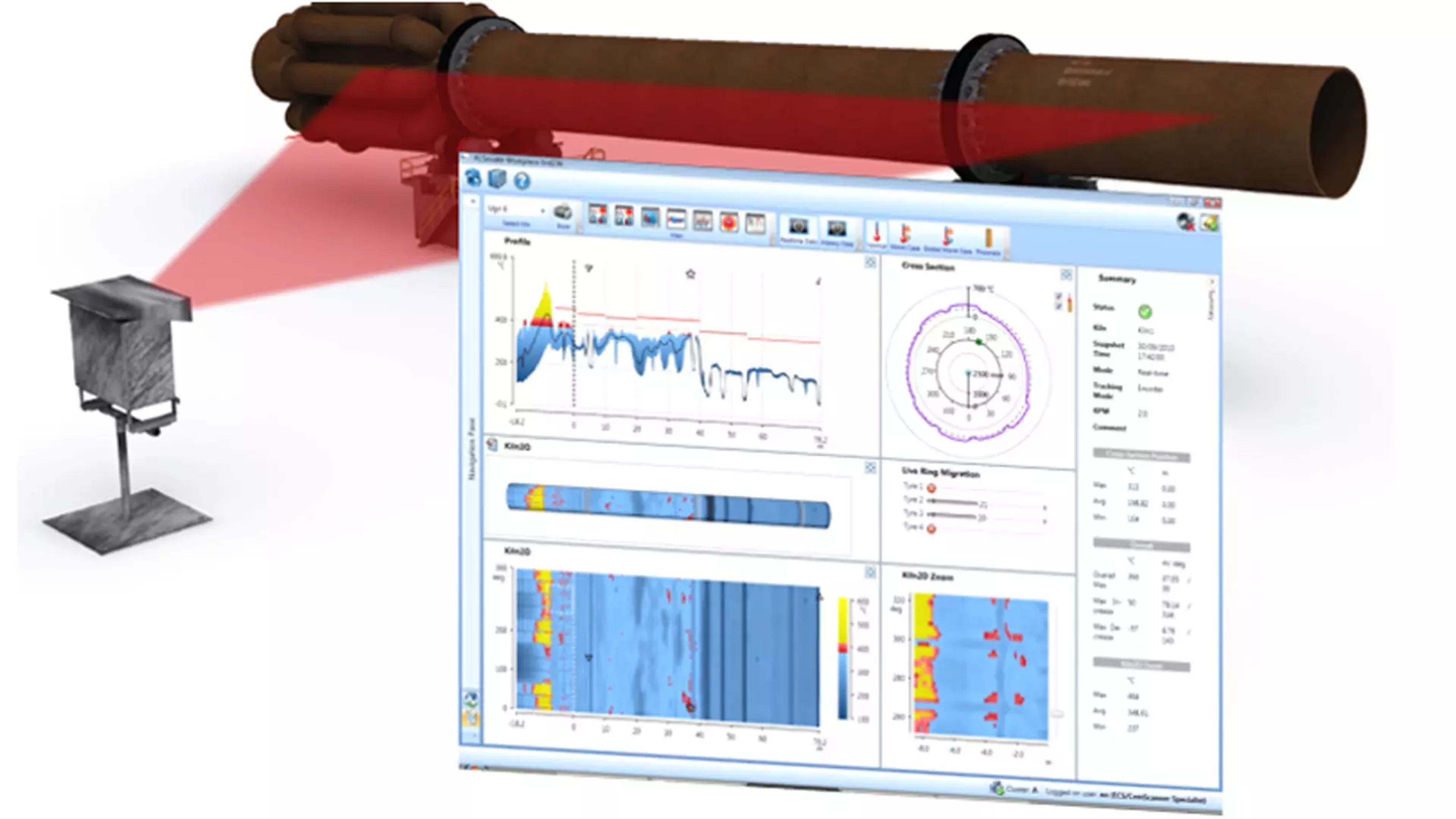

ECS/CemScanner allows you to monitor the temperature of your kiln shell in real time, which is vital to ensure it is operating efficiently. Our scanner system combines a robust design with advanced software features, which make it an indispensable aid to the operation and optimisation of your kilns.

How does it work?

Our system uses a state-of-the-art infrared scanner to construct a thermal image of the entire flattened shell surface of your kiln. The thermal profile consists of four super-imposed curves showing the minimum, maximum, average and worst-case temperatures around the shell and may also display the alarm levels assigned to several kiln sections. This gives you the information you need to adjust conditions inside the kiln to protect your equipment and boost your performance.

Over time, ECS/CemScanner will provide significant benefits to your business. You’ll be able to spend less on kiln maintenance, experience fewer stops and be able to plan shutdowns. Plus, you’ll benefit from increased kiln availability and lower refractory consumption.

Reduce kiln downtime, increase plant availability

We’ve used our decades of experience in kiln monitoring to bring you the most advanced system possible. Our system will protect your kiln and save you money on repairs while reducing costly unplanned downtime.

Minimises downtime and refractory repairs

ECS/CemScanner makes it possible to identity hot spots and ring deformations early, allowing you to take action to protect your kiln from unnecessary wear. By protecting your kiln you’ll be able to minimise downtime from outages and repairs.

Increased kiln availability

With less need for downtime and repairs, your kiln will be available for use more often. You’ll be able to lift output even as you’re saving on repair costs.

Improve your operational control

By understanding and monitoring the thermal profile of the kiln, you can take decisions to optimize your temperature, fuel usage and reduce process variability resulting in a more stable operation.

Ability to plan shutdowns

Our ECS/CemScanner allows you to better manage lining wear inside your kiln, so you’ll be able to better plan for maintenance. That way, you’ll be able to avoid the huge costs associated with unplanned shutdowns and ensure your kiln is back online more quickly.

Monitor and protect your kiln

Our ECS/CemScanner is equipped with a number of advanced tools to help monitor and protect your kiln. Your operators will be able to get a better understanding of conditions inside the kiln and you’ll be able to better harness their knowledge when it comes to planning for refractory replacements.

Kiln protections

Our system comes with built-in protections for your kiln, including tyre-slip monitoring and fan control. By monitoring for tyre slips, you’ll be able to anticipate and predict kiln constriction, helping to lengthen the life of your kiln. Additionally, the option to automate control of the fans in the burning zone section will ensure they are used when and where they are needed, rather than operating continuously and uneconomically.

Monitor brick coating

ECS/CemScanner is able to calculate brick and coating thickness and display the results as a three-dimensional image that’s updated in real time or based on historical data. This calculation is not an estimate but is based on solid theoretical grounds and accounts for different conductivities of the bricks, internal temperatures and conditions causing abnormally high shell temperatures. Your operators will also be able to use our system’s walk-in-the-kiln view, which allows them to better monitor conditions inside the plant.

Refractory management

Your plant operators will gain valuable knowledge on the job when it comes to the performance and useful life of the refractory in the kiln. But unless this information is centralised and recorded you’ll never be able to use it efficiently when it comes to planning new refractory lining. Our system comes with an optional package, BrickGuide which will allow you to manage all the relevant information on refractory track-record, consumption and past installations. The software package includes a graphical presentation of the history of the installations, lining arrangement, consumption and performance reports for each installed brick type in the kiln.