Cement grinding with our highly efficient ball mill

What we offer

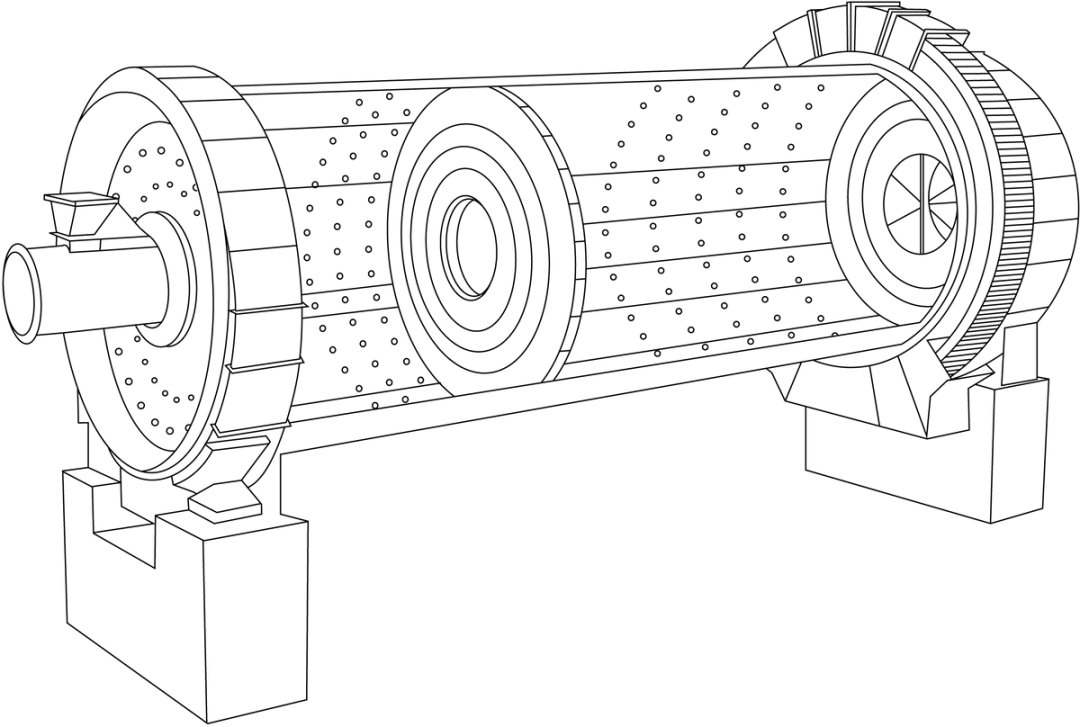

The ultimate ball mill – with flexibility built in

You can’t optimise cement grinding with a one-size-fits-all solution. That’s why our ball mills are designed to adapt to your requirements, with a high degree of flexibility built in. You decide whether to operate the mill in open or closed circuit, with or without a pre-grinder and with side or central drive, according to your plant layout and end product specifications. Even the lining types are tailored to your operating parameters. This customised approach ensures you get maximum grinding efficiency with minimal maintenance. In addition, the large through-flow areas enable the mill to operate with large volumes of venting air and a low pressure drop across the mill. This reduces the energy consumption of the mill ventilation fan and keeps your energy costs down.

Proven design. Low maintenance. High efficiency.

Robust and reliable, flexible design

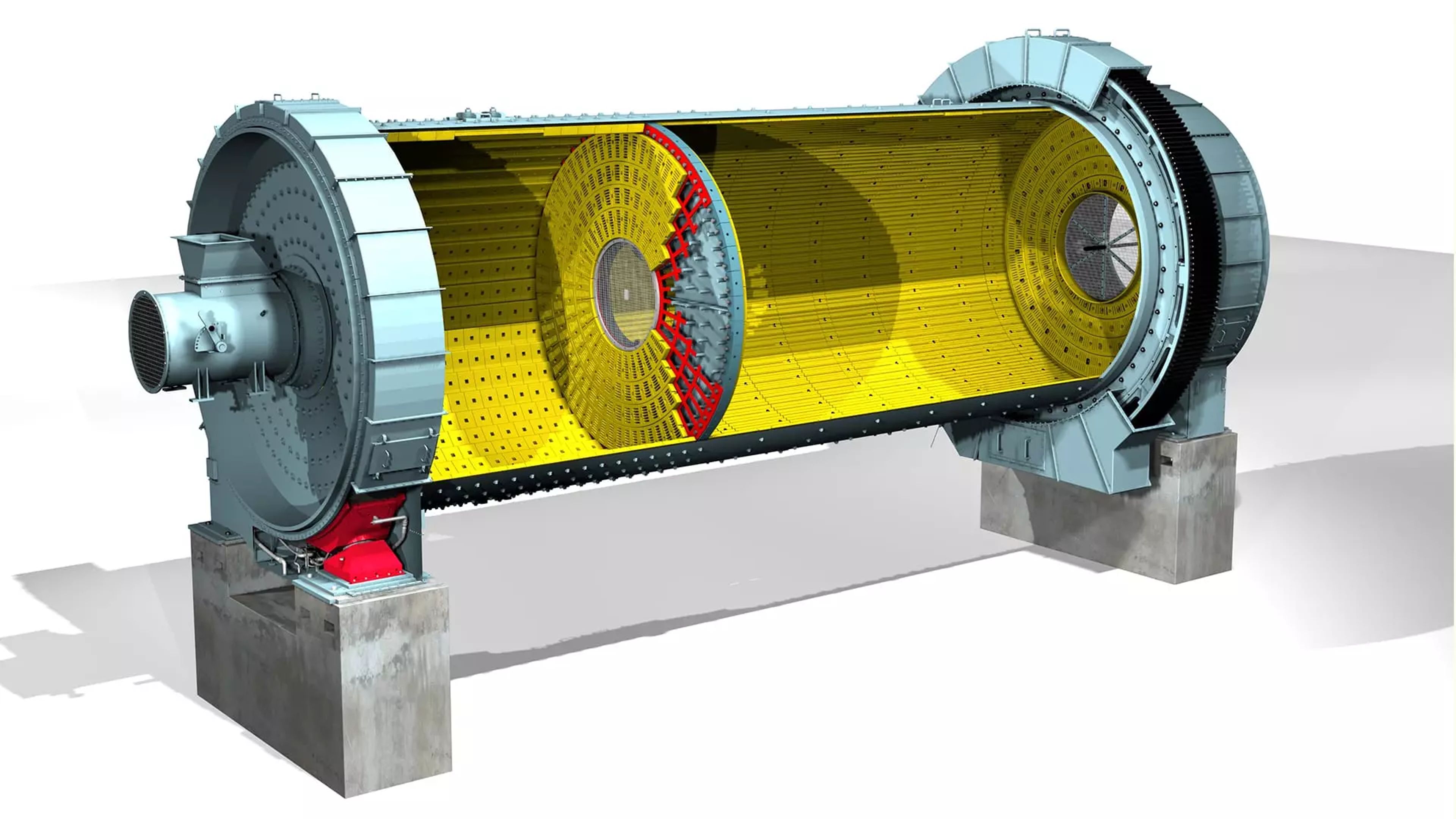

The mill is based on standard modules and can be adapted to your plant layout, end product specifications and drive type. The horizontal slide shoe bearing design enables much simpler foundations and reduced installation height, making installation quicker and less expensive. Our shell linings are designed to suit the task at hand. In our two-compartment cement mills, the first compartment (for coarse grinding) has a step lining suitable for large grinding media. It protects the shell while ensuring optimum lifting of the mill charge. In the second compartment (and also in our one-compartment cement mills) we use a corrugated lining designed to obtain the maximum power absorption and grinding efficiency. For special applications, we can supply a classifying shell lining for fine grinding in the mill. In fact, the entire mill is protected with bolted on lining plates designed for the specific wear faced by each part of the mill. This attention to detail ensures both minimal wear and easy maintenance. When a wear part has reached the end of its life, it is easily replaced.

High grinding efficiency

The grinding media are supplied in various sizes to ensure optimum grinding efficiency. The STANEX diaphragm is designed to maximise the effective grinding area, enabling a higher throughput. It is fitted with adjustable lifters to ensure the material levels in each compartment are right. Best of all, the STANEX diaphragm works for all applications, even when material flow rates are high and the mill feed is moist.

Low pressure drop

The large through-flow area ensures low pressure drop across the mill, further reducing energy consumption.

Simple maintenance

Each grinding compartment has two man-hole covers to give easy access for maintenance. As there are minimal moving parts, the maintenance requirement is low and simple changes like replacing wear linings and topping up grinding media can be completed quickly and easily. Horizontal slide shoe bearings prevent oil spillages from the casing and offers easy replacement of slide shoes.

Reliable cement grinding based on a century of experience

Buying a new mill is a huge investment. With over a century of ball mill experience and more than 4000 installations worldwide, rest assured – we have the expertise to deliver the right solution for your project. Our ball mill is based on standard modules and the highly flexible design can be adapted to your requirements. The mill comprises the following parts.

Mill body

The mill body consists of an all-welded mill shell and a T-sectional welded-up slide ring at either end, the cylindrical part of which is welded onto the ends of the shell. The mill shell has four manholes, two for each grinding compartment.

Slide shoe bearings

Much simpler foundations and reduced installation height - lower civil costs Uncomplicated alignment of base plates for lower installation time and cost Independent installation of slide shoes and casing Simple installation of casing No oil spillage from bearing casing – low maintenance time and cost Easy replacement of slide shoes if needed – faster replacement, lower downtime No risk for blocking of moveable bearing since rollers are removed Each slide ring runs in a bearing with two self-aligning and hydrodynamically lubricated slide shoes. One of the slide shoes at the drive end holds the mill in axial direction. In the others, the slide rings can move freely in axial direction to allow for longitudinal thermal expansion and contraction of the mill body. The slide shoes are water-cooled, and each bearing is provided with a panel-enclosed lubrication unit including oil tank, motorised low- and high-pressure oil pumps, as well as an oil conditioning circuit with motorised pump for heating/cooling and filtration of the oil.

Inlet

The stationary steel plate inlet duct leads the venting air into the mill. It is equipped with a manually operated throttle valve and a pressure monitor to adjust the pressure at the inlet end, thus preventing dust emission from the inlet. The feed chute is lined with bolted-on wear plates and slopes down through the air duct to the mill inlet opening.

Outlet

The stationary steel plate outlet casing is insulated with mineral wool and provided with seals between the casing and the rotating outlet cone.

Controls

The more control you have over the mill, the better your grinding efficiency is likely to be. Our ball mills include monitoring systems to continuously measure the material and air temperatures as well as the pressure at the mill exit. The venting of the mill is adjusted by a damper in the inlet to the mill fan. And the material fill level is continuously monitored by means of sensors. For ball mills operating in closed circuit, the circulation load is monitored by weighing the flow of reject material from the separator. These measures ensure you achieve optimum mill performance, giving you the quality, efficiency, safety and reliability that you need.