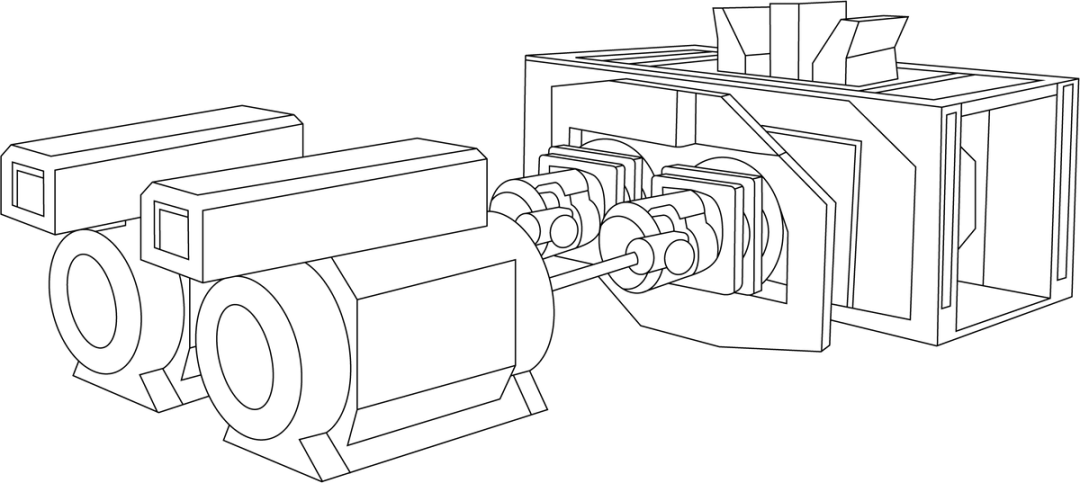

Our Hydraulic Roller Press offers flexible feed material grinding

What we offer

Reliable feed material grinding with our Hydraulic Roller Press

Due to its flexibility, reliability and energy efficiency, our Hydraulic Roller Press System, also known as the HRP system, is widely used in the cement industry. Hydraulic Roller Press comminution subjects the feed material to a very high pressure between its counter rotating rollers over a short time. The pressure exerted forms micro cracks in the feed particles, leading to the generation of a large amount of fine material. The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing.

Improve production while reducing energy consumption

The flexible Hydraulic Roller Press is suitable for both upgrades and new installations. Upgrading from a conventional grinding system can, in some cases, more than double your production capacity, while also reducing specific energy consumption by 30 percent. In ball mills, for example, less power is required to produce finished cement from Hydraulic Roller Press-pressed material than from un-pressed material.

Adaptable to three different grinding setups

Our Hydraulic Roller Press offers maximal flexibility as it can be incorporated into three different grinding installation setups: pre-grinding, semi-finish grinding and finish grinding. In a pre-grinding setup, the Hydraulic Roller Press grinds the fresh feed and a specified amount of recirculated pressed flakes. This material mix then undergoes finish grinding in a conventional ball mill circuit. In comparison to a conventional ball mill system, this configuration provides an increase in production of approximately 25 per cent and a reduction in specific power consumption of approximately 10 per cent. Where semi-finish grinding is desired, the Hydraulic Roller Press can be combined with a two-stage separator system and a conventional ball mill. A dynamic separator, which maintains the desired quality of the final product is paired with a static separator that ensures effective deagglomeration and aids in drying the feed material. Upgrading a conventional ball mill with the Hydraulic Roller Press for semi-finish setups can increase production by up to 100 per cent or more, while also reducing specific power consumption by approximately 30 per cent.\n\nIf the Hydraulic Roller Press is used for finish grinding in a closed circuit with the two-stage separator system, the need for other grinding equipment is eliminated. The reliable Hydraulic Roller Press outperforms ball mills and vertical mills when it comes to finish grinding. While the Hydraulic Roller Press can be used to upgrade ball mill systems for energy efficiency and enhanced production benefits, it is also exemplary in upgrading your vertical roller mill. The resulting benefits include increased production, without any increase in specific energy consumption, and increased availability of the overall grinding system.

Maximise feed material grinding with the Hydraulic Roller Press

High energy efficiency

Compared with a conventional grinding system, the Hydraulic Roller Press can reduce specific energy consumption by 30 percent. The two-stage separator has low power consumption of the separator fan and helps to maintain high energy efficiency of the overall grinding station.

High availability and reliability

The long-life wear parts offer minimal operational disruption as they require less frequent maintenance. Furthermore, the solid-forged single piece rollers together with oil lubricated spherical bearings ensures high availability and reliability of our Hydraulic Roller Press.

Low operational and maintenance costs

The Hydraulic Roller Press’s exceptional design helps to improve operational efficiency and reduces energy consumption. The hinged frame allows easy removal of the rollers for maintenance and long-life wear roller parts result in less frequent replacement of costly parts.

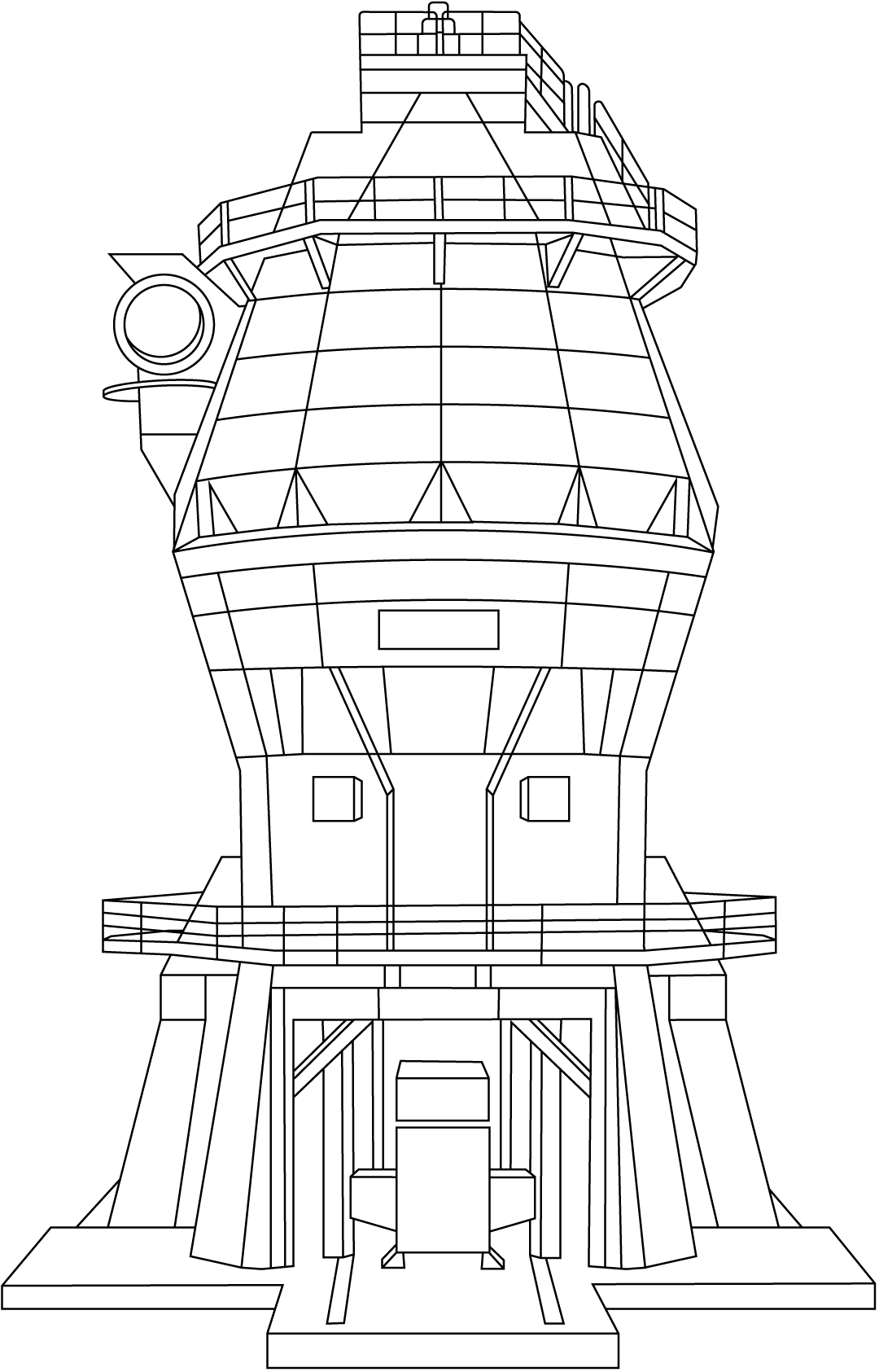

Compact layout with an isolated foundation

Designed with a compact layout, the Hydraulic Roller Press offers easy installation and therefore, reduced civil and structural costs. It has its own foundation that is isolated from the rest of the building, preventing vibrations that can accelerate foundation and equipment wear and tear. Having its own foundation also reduces building strength requirements.

Long-life wear parts

Grinding highly abrasive feed materials at high pressures around the clock can result in fast wearing of parts. To withstand such conditions, the Hydraulic Roller Press has the strongest and most durable roller wear surface available, an FLSmidth innovation called TRIBOMAX®.

Flexible grinding solution with our hydraulic roller press

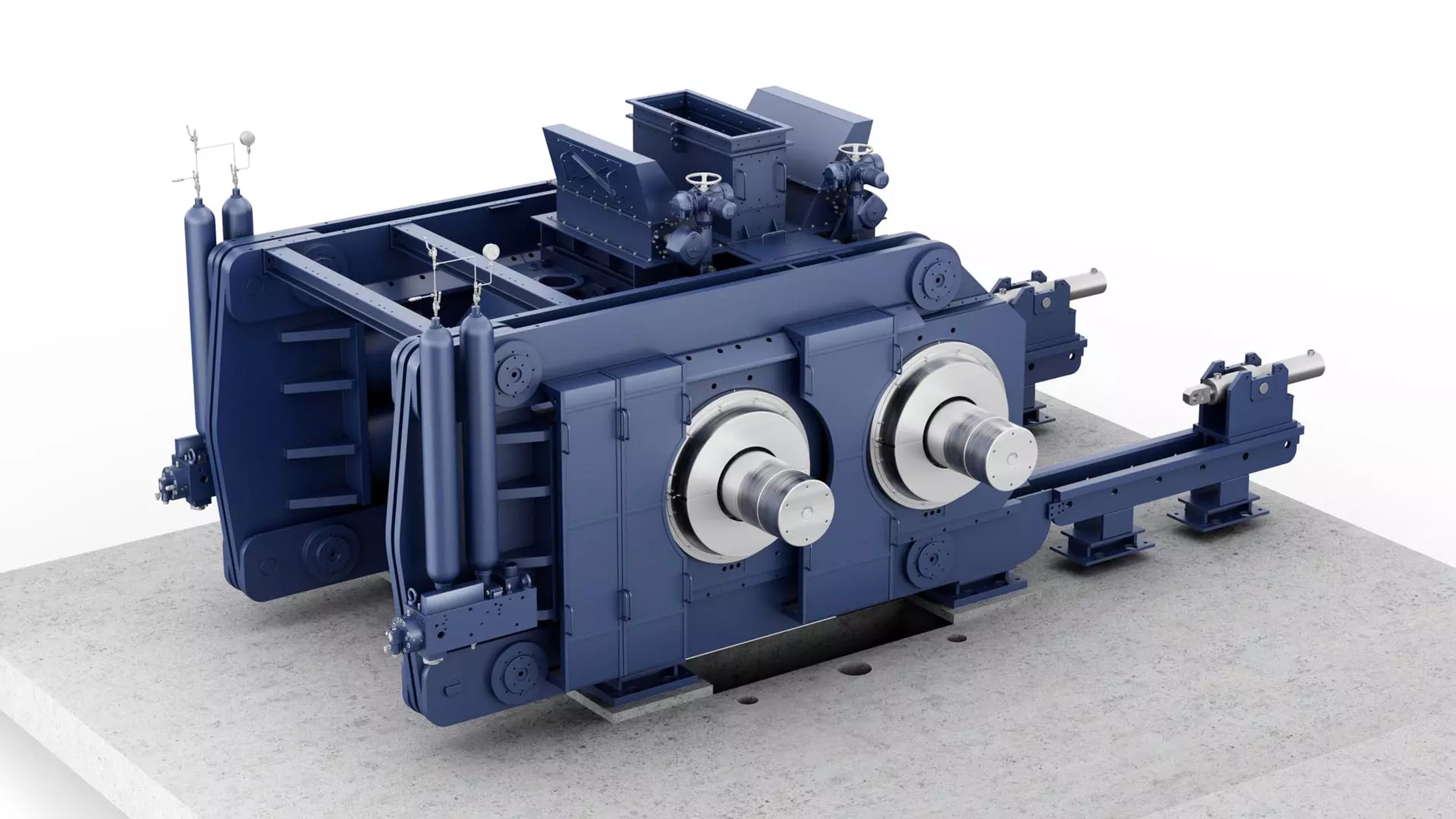

All eyes on the rollers

The Hydraulic Roller Press has solid-forged, counter-rotating rollers with no hollow shaft resulting in long equipment lifetime. The rollers have an optimum diameter to width (D/W) ratio that: Helps maintain the robustness of the rollers Increases acceptability of high feed size Allows for better distribution of feed materials over the entire width of the rollers Reduces the roller rotational speed for a given peripheral speed Our unique roller wear surface TRIBOMAX® is the strongest and most durable surface available, and is applied to the Hydraulic Roller Press rollers using a special state-of-the-art welding technology. TRIBOMAX® has a 25,000-hour minimum guaranteed lifetime for Clinker grinding applications and can be designed to guarantee up to 40,000 hours of lifetime in select cases. We also provide conventional wear surface for applications in which your feed materials don’t have high abrasiveness. The roller design and long-life wear surfaces ensure high availability and reliability of the Hydraulic Roller Press resulting in reduced operation and maintenance costs.

Bespoke separator system handles all feed material

The two-stage separator system uses different separators for raw material grinding and clinker grinding applications. Put simply, the system is made up of a dynamic separator and a static separator. The dynamic separator exhibits low velocity through its rotor cage while the compact static separator establishes optimum velocity in the coarse separation zone. Our separator system is well known globally for its top-of-class efficiency.

Smart bearing configuration for smooth operation

Spherical roller bearings help to accommodate angular misalignments during operation. A sophisticated oil lubrication system provides bearing lubrication, cooling and filtering of lubrication media. Further, bearings mounted on the withdrawal sleeve allow easy and safe removal for maintenance.

Flexible, smooth and safe operation

The highly-sensitive metal detector recognises any metal-based foreign materials in the feed material, allowing identification and removal to ensure enhanced protection of the Hydraulic Roller Press. The metal detector also gives more flexibility when adjusting the ‘zero gap’ between the rollers.

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)