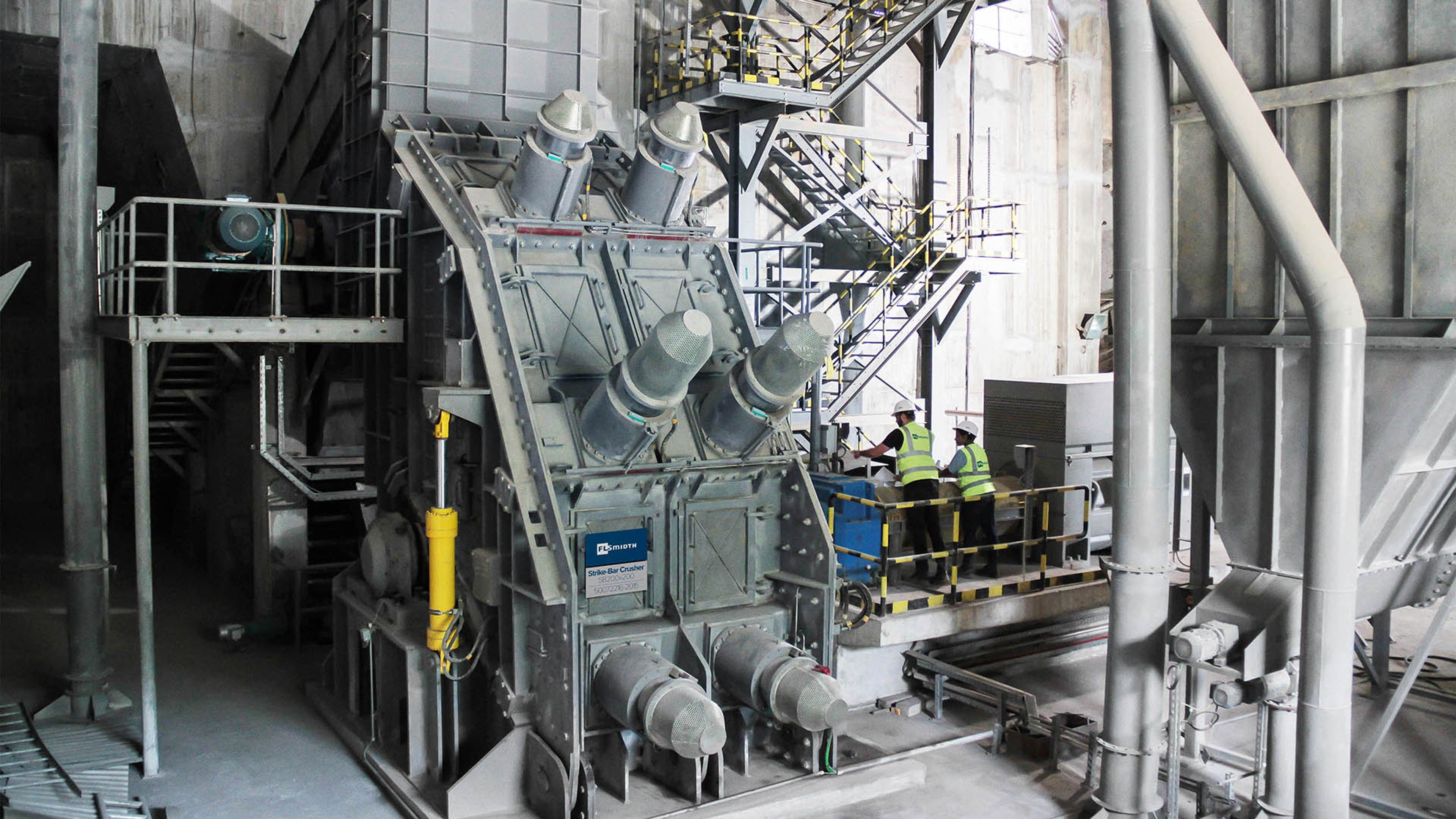

Improve reliability and performance with crusher maintenance services

What we offer

Eliminate the root causes of crusher problems

When the crusher goes down, it puts a lot of strain on your process – and your people. But this stressful situation can be avoided if you look for the signs that something is going wrong in your system. Excessive vibration, chain wear and repeated failures are all indications that your crusher needs attention. Our onsite crusher maintenance services look for these root causes, enabling you to act on them before they escalate.

Close examination and good maintenance

Close examination and good maintenance of your crusher protects your plant’s overall productivity. By acting fast, you can avoid poor performance, stoppages and costly repairs.

Regular crusher inspections

Our regular crusher inspections and ongoing technical support ensure your equipment keeps operating at maximum efficiency.

Hammers, vibration analysis and balancing of crusher components

In addition to these comprehensive inspections, our crusher maintenance services include hammers, vibration analysis and balancing of crusher components. We also offer everything from apron feeder alignments and retrofit to spare parts replacements, always working closely with you to oversee repairs and ensure all correct tolerances are achieved.

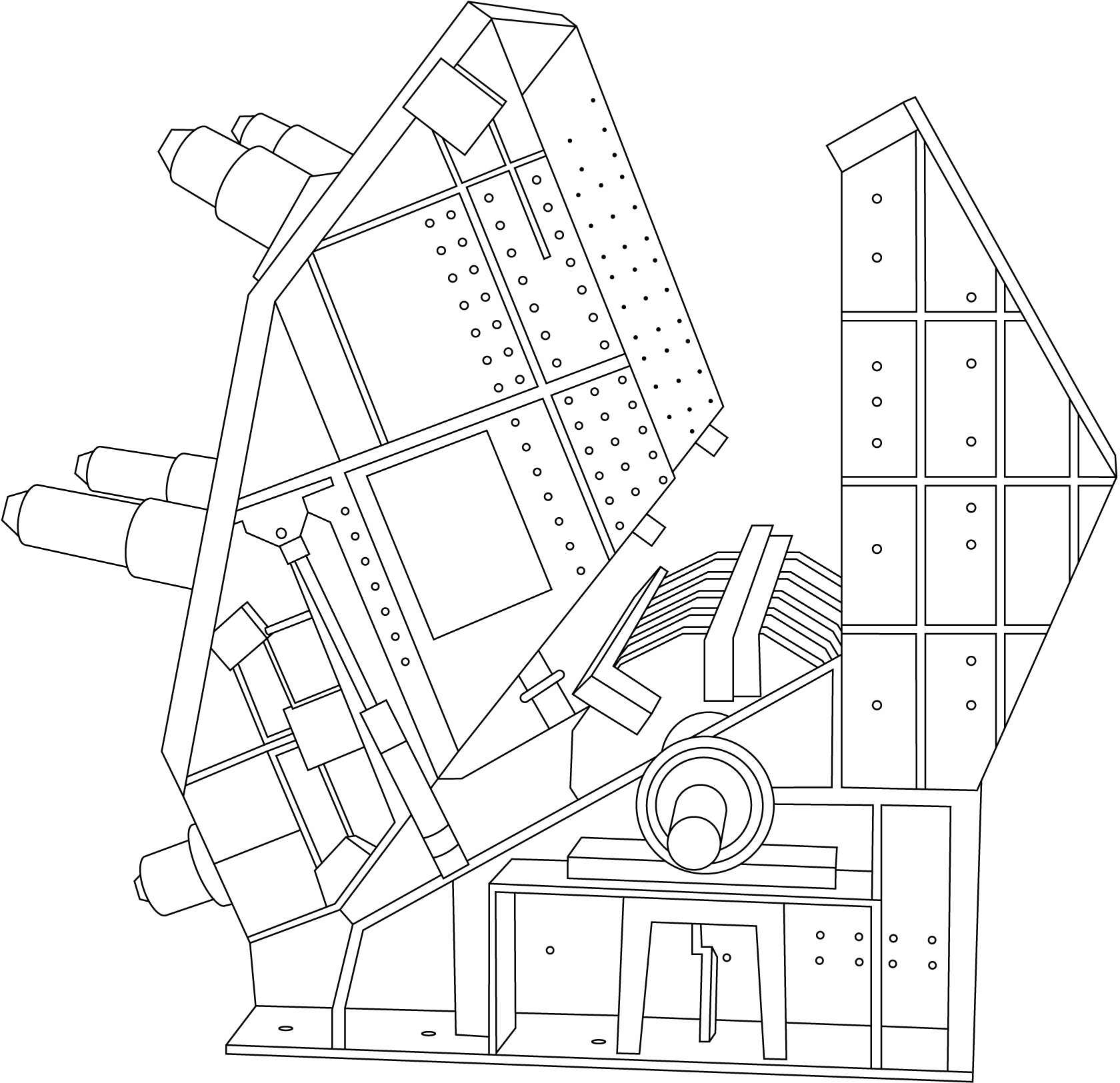

Crusher maintenance inspection

As an OEM, we understand crushers and the pressures the crushing operation exerts on the machinery. We’ve used this knowhow to design a comprehensive crusher maintenance inspection that looks at all components in great detail to ensure none of the aforementioned root causes – or indeed, symptoms of root cause problems – are missed.

Cut downtime, cut costs

When you take a predictive maintenance approach, you stop being reactive and start being proactive. Regular crusher inspections enable you to identify issues that need to be addressed, and how quickly you should act, so that you can avoid unplanned outages. The supporting crusher maintenance services are carried out to OEM standard, giving you peace of mind that your spare and wear parts will last.

Reduce downtime

By responding to the first signs of a problem, you automatically reduce downtime – because you’re dealing with much smaller repairs than if the problem had been left to grow and affect other components.

Improve productivity

Reduced downtime results in greater availability and higher productivity. You are no longer losing production time to maintenance tasks.

Cut maintenance costs

Less maintenance means less maintenance costs. Being proactive allows you to avoid the big-money failures, freeing you up to invest in other projects.

Increase product quality

A higher performing operation enables you to achieve a more consistent standard of crushing, increasing the quality of your crusher product and benefiting your entire process.

_Crusher.png?w=3840&q=80&auto=format)