Flexible and efficient electronic rotary packers for valve bag filling

What we offer

Rotary packing machines for cement and granulated materials

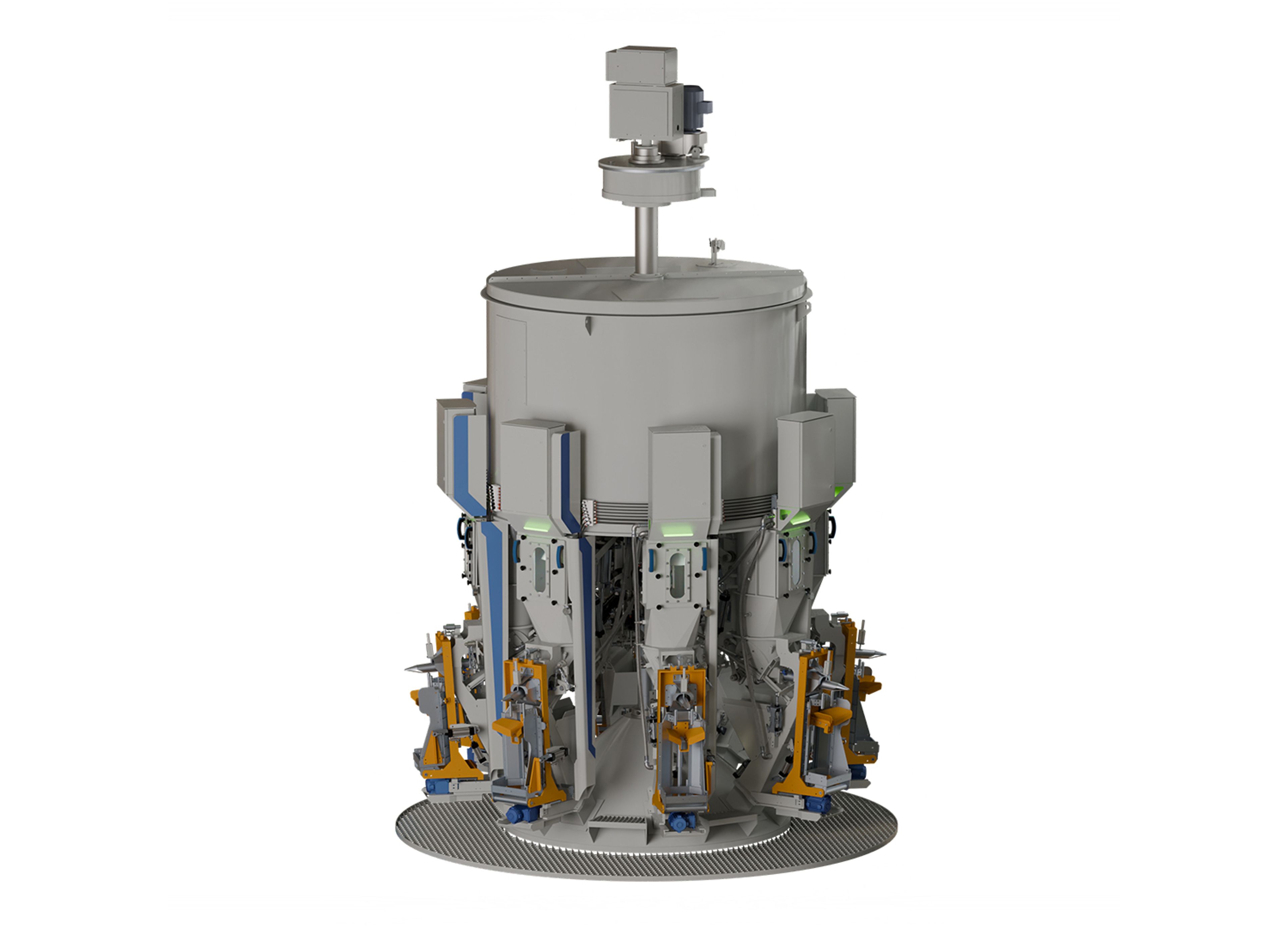

Rotary packers have come a long way. Where once every machine would have to be operated by a human placing bags on spouts and manually controlling the fill level, today’s machines are entirely automated. We’ve played a major part in that evolution – as the first manufacturer to develop a microprocessor-based controller for filling and weighing units on packers, and then as the first to introduce the electronic rotary packer. Our latest innovation is the new GIROMAT® EVO rotary packer generation. Its compact and modular design is both flexible and expandable, up to 16 spouts and with an output up to 4800-5000 bph of 50 kg and 5300-5600 bph of 25 kg .Designed for bagging cement and other building materials, it comes in a range of configurations, such as: Impeller or fluidizing (air type) filling technology according to product; Bag clamping device for glued and stitched bags; suitable for various bag construction material; Rapid discharge for quick product change-over; and bag sealing system based on ultrasonic technology.

Modularity and flexibility

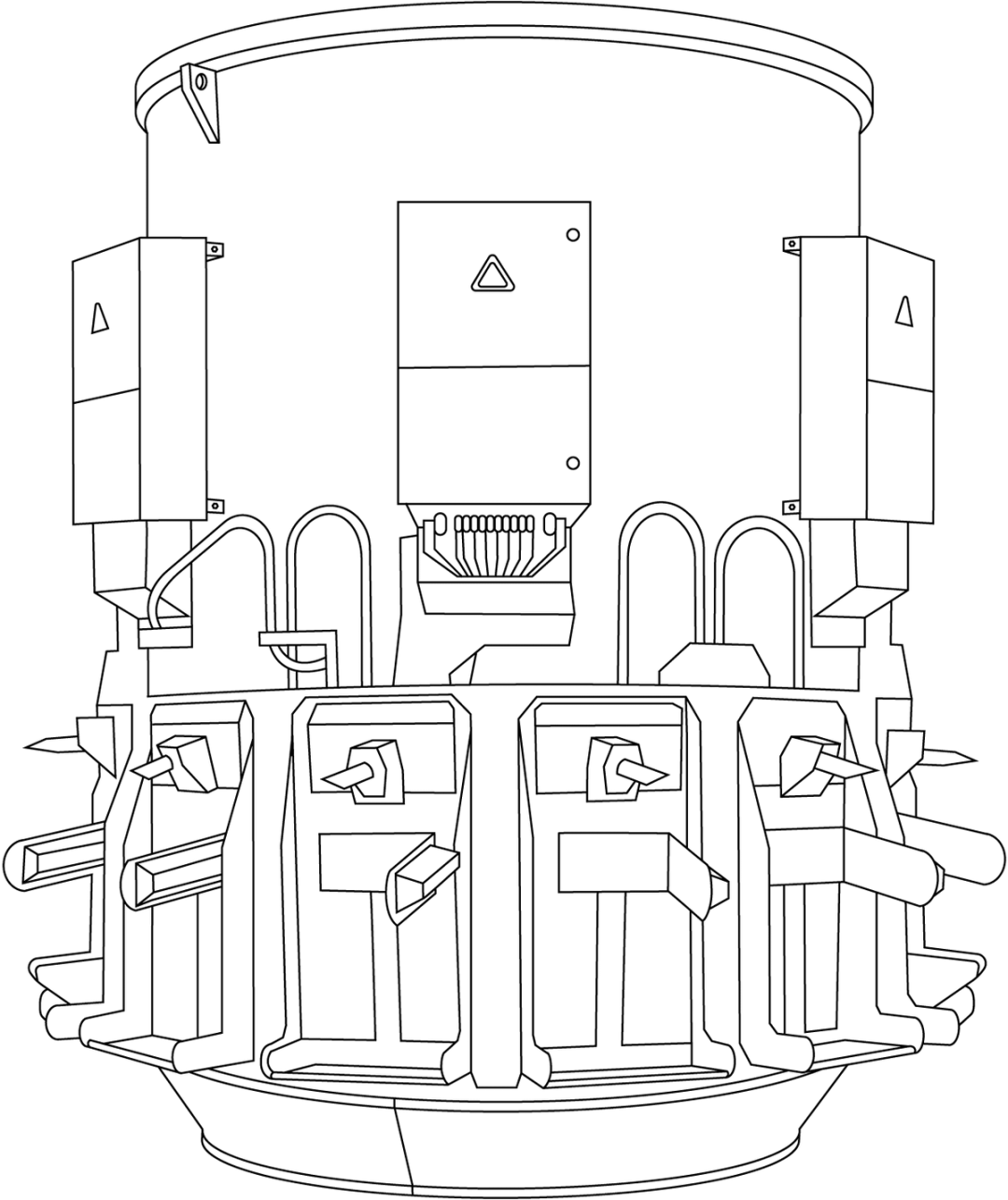

For easy installation, Ventomatic® packers are composed of a number of preassembled modules, all of which are prepared and tested before delivering. These modules are quickly and easily mounted on the central tank of the packer during installation. We make it really simple: the pneumatic connector plugs and electric rapid connectors are numbered so you know exactly what fits where. This modular design enables you to put the packer into service with a reduced number of bag filling units. When you need to increase production, you simply add more filling units.

Enhance your productivity with GIROMAT® rotary packing machines

VENTOMATIC® rotary bag packers

Electronic concept

The packer is equipped with the latest generation of electronic weighing units, EWU (OIML approved), encoder and optical connection.

Suitable for different bag sizes and weights

Available for a wide-range of bag types, sizes and weights with manual or automatic adjustment.

Designed for powders, granulates and minerals

Ideal for cement, dry mix, gypsum and other powdery products. The handling capacity can be expanded thanks to the modular concept . Different unit design is available according to product characteristics.

Modular design

The filling units are modular, making it easy to install and disassemble for quick maintenance. We’ve also improved the design to further reduce dust emissions.

Driving growth in cement packing with efficient rotary packers

Optical connection

An infrared data transmission device connects the filling units (mounted on the rotating part), the operator panel and the control system.

Electronic weighing unit

We’ve designed a multiprocessor electronic weighing unit specifically designed for bagging applications.

Filling unit

Valve bag filling that is designed for high weighing accuracy, high output and low dust emission.

Impeller type

With vertical or horizontal axis and with different profiles according to the product characteristics. Air type filling units suitable for building material, ready mix and granulated materials. Tell us what you need and we’ll help you select the best solution.

Regulation

Complete automatic adjustment for multiple bag sizes, weight parameters selection from 10 – 60 kg, rapid discharge for fast product change over, and modular execution of filling modules.

Ventomatic® GEP Packer - Engineered for Diversified Production

If you’re juggling multiple product lines and ever decreasing bag sizes, you need the Ventomatic® GEP packer – a rotary packer designed to handle quick product changes and varying bag sizes, all with minimal manual intervention. With automatic cleaning cycles that eliminate manual product changeover procedures, position-controlled flow gates requiring zero manual regulation, and intelligent product detection sensors that work across diverse materials without calibration, this advanced bag filling machine is low effort and low energy. Selective aspiration technology optimises energy consumption by activating only when needed. Enhanced flow geometry and smart controls deliver consistent fill weights while reducing product waste, while tool-free maintenance features enable sleeve replacement in under 3 minutes. The result is faster changeovers, improved quality consistency, reduced labour dependency, and lower operating costs - enabling profitable small-batch production in today's demanding market environment.