Lift plant performance with ECS/ControlCenter process control

What we offer

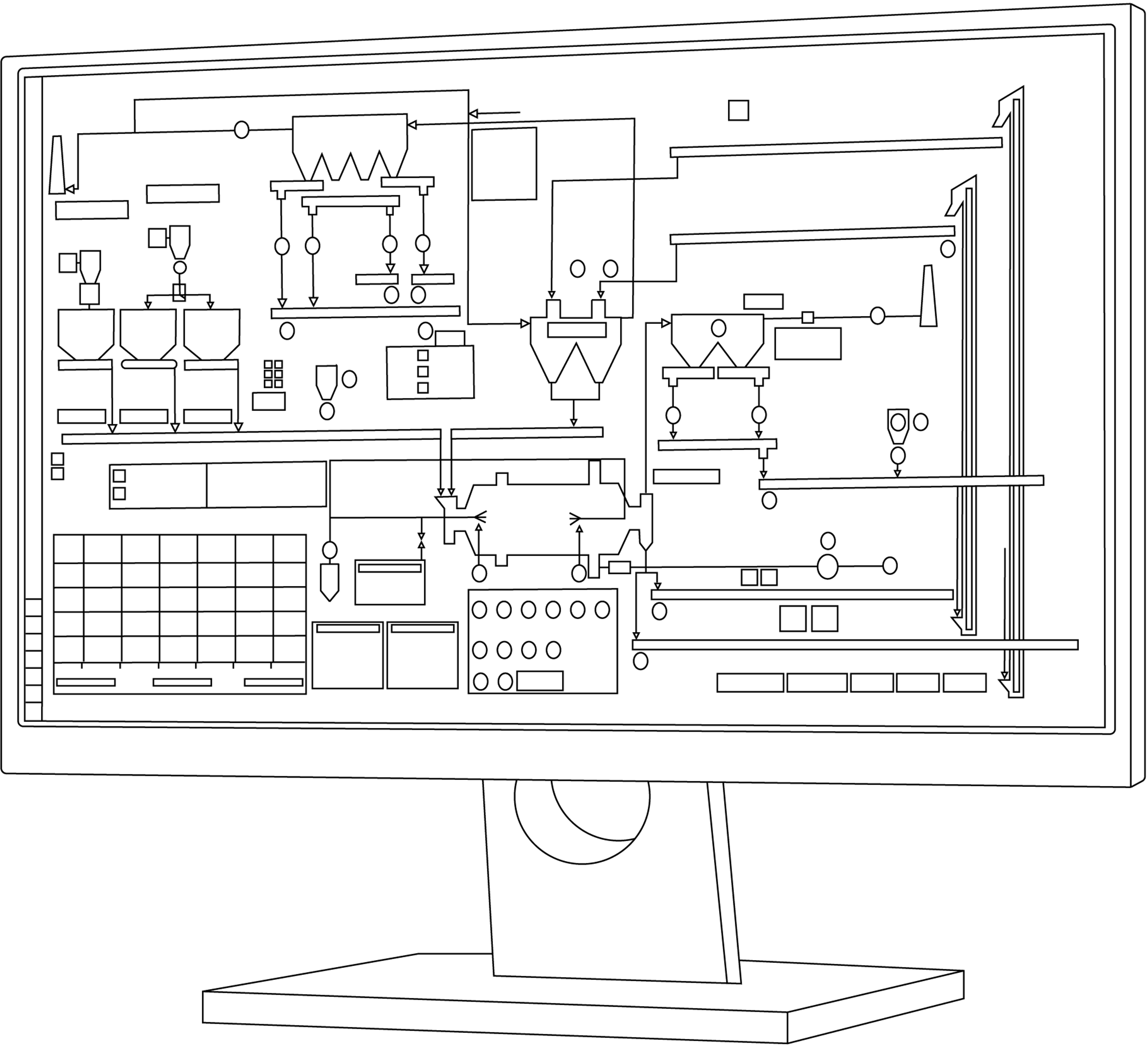

Optimise your operation with user-friendly process control software

In today’s landscape of rising costs, increasingly stiff competition, and rising environmental pressures, you need a reliable control system now, more than ever. Our ECS/ControlCenter process control solution offers just that. The product of more than 40 years of innovation in process control and engineering, it’s designed to deliver secure and reliable performance based on your needs, delivering the most advanced yet simple-to-use solution on the market.

Complete and reliable plant process automation

Tailored specifically to process industries, the ECS/ControlCenter software delivers reliability and security – as well as usability – in one advanced package.

Cybersecure systems

The ECS/ControlCenter solution features server, network, and PLC redundancy to ensure continuous operation, while a defence-in-depth approach delivers enhanced security with granular access control, tested patch update, firewalls, network segmentation, and endpoint security.

Hardware agnostic

We don’t tie you into proprietary hardware. Our ECS/ControlCenter software is designed to support best-in-class computer, network, controller, and IO hardware from the complete range of suppliers, including Dell, Cisco, Siemens, Rockwell, Scheider Electric, Fortinet, Beckhoff, and Phoenix Contact.

Easy to engineer and scale

Our advanced standard function block library delivers reliable plant control and allows easy parameter changes, without specialised programming knowledge, while automatic PLC programs generation further ensures standardisation and consistency, while also facilitating maintenance and system expansion.

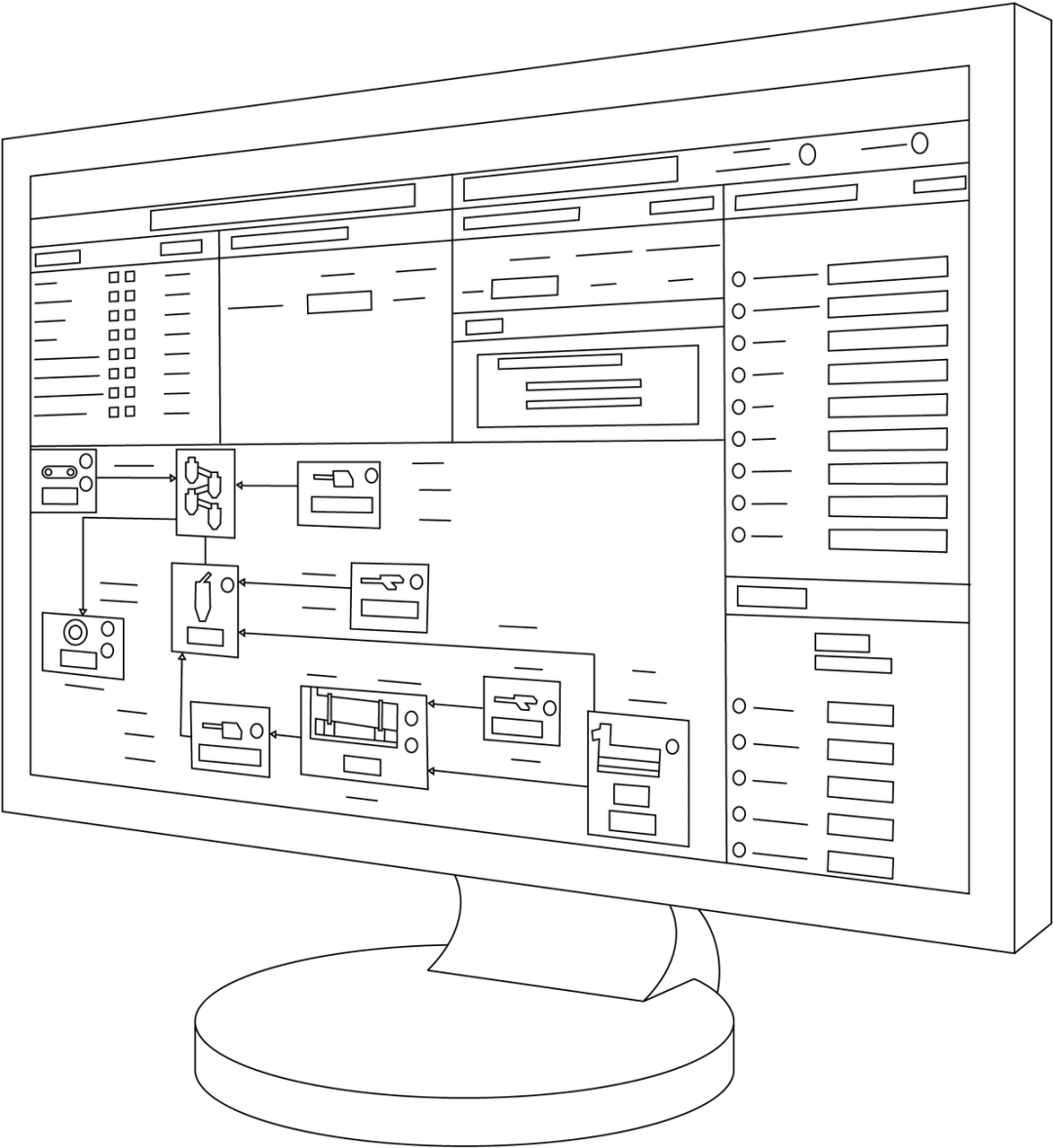

Personalised user interfaces

Configurable role-based user interfaces help keep operators focused on what is relevant to them, while our ISA 18.2 alarm management system comes with automatic alarm suppression by hierarchy to reduce the number of nuisance alarms and prevent information overload in critical situations.

Lifecycle reliability

Our PlantLine service agreements keep your systems running reliably, with 24/7 phone, chat, or remote service available in emergency situations. Software subscriptions are available to keep your system up-to-date and security patched, while our cybersecurity services prevent attack and system downtime.

Product features

Process control by process experts

We’ve designed the ECS/ControlCenter process control solution with a range of features that support your operators run the plant, consistently, day in, day out.

DCS functionality with PLC flexibility

Based on our PLC-brand agnostic ECS/ACESYS™ advanced standard function block library, the ECS/ControlCenter system offers a hybrid solution, combining the benefits of traditional DCS systems with the flexibility of modern PLC/SCADA systems.

Inbuilt data historian

The inbuilt data historian logs all process, alarm, and event data for one year at full resolution, using a ‘swinging door’ algorithm, which logs data only when it changes to preserve disk space. Longer time horizons are possible with an optional ECS/PlantDataManagement server.

Trend anything any time

All analogue and digital signals and statuses are logged automatically and continuously. This data can be presented in any combination as trend curves, with the ability to compare up to 16 signals in the same view. Pick from pre-built trend packages, build your own, or simply drag and drop tags onto the trend screen from the HMI without the need for an engineer or admin user. The trend system is responsive, with most trends opening within 1-3 seconds; trends data can also easily be exported to a file for further data analysis.

Fast fault detection

The software provides the tools you need to find faults quickly. Your operators and maintenance staff have access to comprehensive information, such as alarm and events, diagnostics, interlocks, trends and statistics, to help them identify the problem and act.

Simple reporting and data export

SQL reporting tools provide a simple interface to basic reporting functionalities, which can be configured with any analogue value or digital status and scheduled for automatic printing or export as required. Data export queries from the SQL database can also be scheduled or triggered by an event, which can be used prompt actions, such as sending a SMS, email, or workplace notification, or playing a sound.

Interoperability and AI integration

Our software easily integrates with other systems, both onsite and Cloud-based, including ERP and data historian systems, via open communication standards. There’s also seamless integration with open-source AI and data analytics tools, such as Jupyter Notebook and Python.

.png?w=1080&q=80&auto=format)