QCX/RoboLab systems: industry’s best cement laboratory automation

What we offer

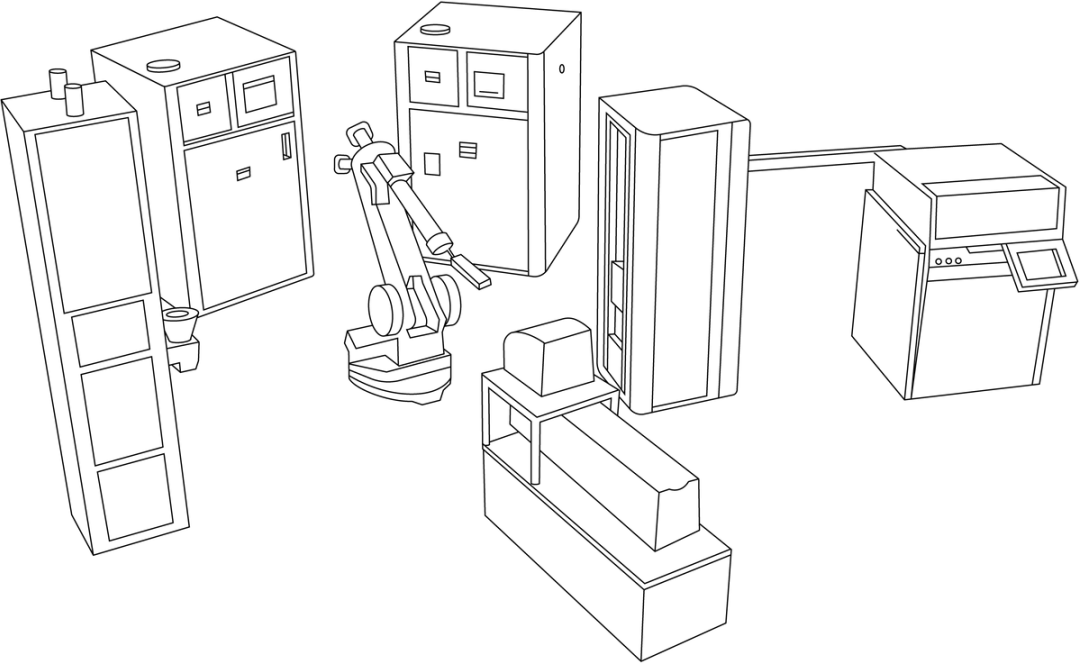

Advanced automation with customised equipment combinations

Our passion for progress and innovation has been shaping our laboratory automation systems since 1971. That’s when we first introduced QCX solutions to cement producers. Over the years, we have applied our deep industry knowledge and drive for improvement to develop the QCX/RoboLab range into a complete solution for quality control in cement. To date, we’ve installed more than 200 RoboLab systems worldwide. QCX/RoboLab is a high-tech robotics solution for automated sample preparation, analysis, and automated quality assurance (QA) and quality control (QC) procedures. This advanced automation system ensures that your process laboratory delivers fast, accurate, and safe analysis – with as few operators as possible. It receives and co-ordinates samples from the QCX/AutoSampling system. Then, depending on your requirements, it can handle some or all the sample preparation and analysis tasks. Capabilities include dosing samples into sub-samples, particle characterisation, sample preparation (for example pressed pellets or fused beads), and analysis methods such as carbon, sulphur and Blaine determination, and XRD or XRF analysis. It’s the system’s modular architecture that makes it so unique, and gives you a high degree of flexibility. It can be tailored to your specific cement production needs, including special cement and alternative fuels. And it can provide any level of automation - from small, task-oriented automation units to a large, fully automated cell. So, you can adopt a phased approach when introducing automation to your laboratory. Most of the equipment is semi-automated. This means units can also be operated manually, and you can keep working even when other parts of the system are being serviced. It teams up seamlessly with other modules in the QCX software range, so you can integrate all your cement quality control activities into a single system. QCX/RoboLab is a tireless worker in your laboratory, giving you foolproof sample analysis, and enhanced productivity.

Meeting the quality control challenge

In today’s cement industry, the increased use of alternative fuels and additives requires stricter controls and special analysis. Accurate results have never been more important. By automating sample preparation, the QCX/RoboLab system gives you reliable results. Sample preparation is more consistent. And the system also avoids sample contamination, with in-built cleaning mechanisms.

Error-free sampling, sample preparation and analysis

QCX/RoboLab eliminates human error, and ensures your samples are readily traceable. Your operation becomes practically unmanned, with the software managing the route that your samples take through fully automated sample preparation equipment and controls the automatic analysers.

Complete documentation and reporting

Sample traceability is also a priority, with ever increasing documentation and audit trail requirements.

Fast and accurate results lead to greater quality control

By letting the computer do the work, you know that your equipment is processing as many samples as possible – giving you vast benefits in terms of throughput. And QCX/RoboLab is designed to keep you up and running 24/7/365, with reliable performance, in-built equipment monitoring, and the FLSmidth global support network at your fingertips.

Labour saving system that promotes safe working environment

Automation not only prevents human error and accidental sample contamination, it’s good news for the wellbeing of your workers, too. QCX/RoboLab eliminates the labour intensive manual processes that can lead to operator injuries, and also protects your workers from hazardous materials such as dust and flux. And by reducing manual tasks, this labour-saving system frees up your skilled technicians for other important work, improving your efficiency.

Scalable as your needs change

The modular architecture of both its hardware and software components allow a user to deploy the system in phases. That is, to extend the sample throughput, the thoughtfully designed circular or linear configuration makes it a child’s play to extend the system by adding a few sample handling or preparation equipment. In other words, the flexible QCX® RoboLab can be scaled up from small task-targeted laboratories to large fully automated laboratories. This modularity is especially beneficial when you add a new raw mill or a cement mill or even an entire production line to the existing plant.

Consistent analysis centred on advanced robotics technology

Unique set up to suit your needs

In a typical RoboLab installation, laboratory equipment is placed in a circle with an industrial robotic arm at its centre. Advanced software controls all the devices in the system. The comprehensive QCX/RoboLab® system includes all equipment drivers, diagnostics tools and informative uniform equipment faceplates. No two RoboLabs are necessarily the same. The system gives you the flexibility to select which laboratory apparatus you need, and scale the system to your required throughput capacity. We offer a wide range of sample preparation and analysis equipment that is supported by the QCX/RoboLab application. RoboLab set ups often include devices for: sample drying sample crushing splitting and dosing milling pressing preparing fused beads or pressed pellets particle sizing by laser or traditional sieving colour analysis combustion analysis for C/S/H20 determination composite sample collection.

Intelligent and fast sample processing

For each individual sample, the powerful software will automatically select the most efficient pathway for it to be prepared and analysed. The programme will even take into account when one or more devices are out for maintenance by automatically routing samples through another available apparatus. Using a barcode system, the software can pair a sample with the desired preparation and analysis recipe. The operator can adjust various parameters in the recipes. The system can store frequently used recipes, or individual settings can be changed as needed. The software’s interfaces are uncomplicated, so selecting appropriate sample preparation and analysis methods is simple. In addition, this smart programme will identify where pre-set instructions are illogical, so you get failsafe processing for each and every sample. The software ensures documented QA. For example, it will duplicate or triplicate sample preparation and analysis, or introduce blank samples at predefined time.

Safe and reliable operation

With QCX/RoboLab, operators are no longer exposed to repetitive and potentially hazardous manual tasks. When the robot is operating, the sample area is locked down, preventing human access. We incorporate safety features as an essential part of design for each of our units. We understand the need for continual operation, 24/7/365. So, all our equipment is designed and constructed for trouble-free, long lasting service. Devices have uniform KPI’s, to make your preventative maintenance planning more efficient. And the equipment has integrated performance metrics to provide valuable usage and performance information, and to enable timely purchase of spare parts. Plus, the system can be configured for remote assistance, for effective troubleshooting and less downtime.