Easy to operate and cost effective bagging machine

What we offer

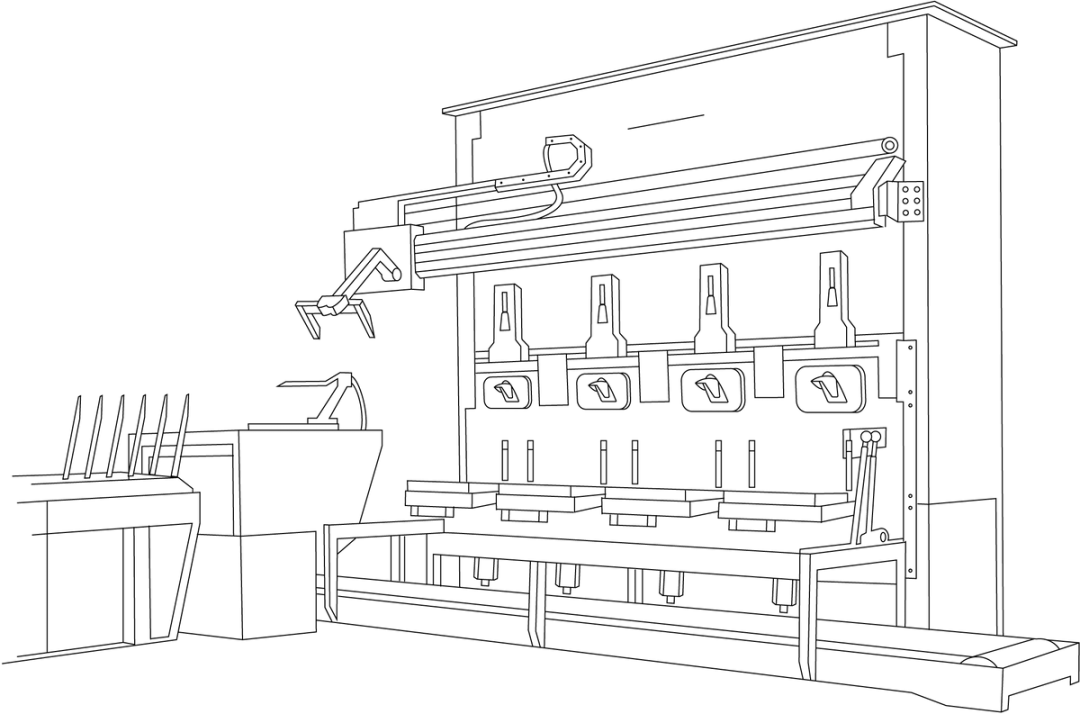

Plug & Play: flexible inline packing machine for granular and powdery products

What kind of materials do you want to pack? What capacities are you producing? When you look for a packing solution for your bagging plant, you have to choose the one that best suits your application. That’s why we have a range of rotary and inline packers designed for a broad variety of applications. Our latest innovation is the new Ventomatic® LINEAMAT™ inline packer. Designed for construction products like gypsum, hydrated lime, cement, mortars, ready mix and minerals, this valve bag filling unit is available with up to four spouts to meet low and medium capacity requirements. It is engineered to deliver optimum filling with low operational costs. It can also be interfaced with LINEAR™ EVO innovative automatic empty bag applicator and NORIAMAT™ empty bag storage and feeding. The new inline packer also comes with integrated digital solutions. Each filling unit is connected to a high-performance CANBUS data network, which sends data on the filling of each bag to the operator panel and optional VENTOLINK™ remote supervision and reporting system. A VENTOCHECK™ belt weighing system can also be hooked up to the CANBUS network, providing bag weighing data to the packer, operator panel and VENTOLINK™. DCS and ERP integration are also possible.

Reliability. Flexibility. Modularity. This is an evolution in filling.

Reliable electronic weighing and control system

The filling unit and impeller profile have been improved to provide a better filling process, with both vertical and horizontal impellers available. Choose from guillotine or pneumatic pinch valve for product flow control, depending on the material. Every filling spout is equipped with an electronic weighing unit for optimum accuracy

Flexible and customisable design

Depending on your application, the Ventomatic® LINEAMAT™ can be supplied with additional equipment for a complete automated packing and dispatch line, including empty bag handling, bag treating systems, spillage recovery system and palletizer with stretch hood.

Modular concept

Easy to install and to maintain, the modular concept also enables easy upsizing of packing lines if required.

Suitable for powdery materials or granulated products

The Ventomatic® LINEAMAT™ can cope with products of various granulometry. The valve bag filling unit is designed to ensure proper product handling, preserving the material characteristics and reducing wear on the packing machine.

High accuracy bag filling and weighing with LINEAMAT™ inline packer

Filling accuracy. Clean bags. High reliability. We know these are your concerns, so they were our focus when we designed the latest version of the Ventomatic® LINEAMAT™ inline packer. With these priorities in mind, we improved the filling process and the weighing accuracy. In the latest innovation, the bag hangs directly on the nozzle to ensure weighing accuracy, as well as homogenous distribution of the product within the bag. The machine has multiple positions, reducing bag deformation, stress and product spillage to a minimum. You can further add an onboard ultrasonic bag sealing system for the ultimate security if required. We’ve also added a feature from our rotary packers that makes it easy to use the same bagging machine for multiple products. Rapid discharge allows for quick product changeover with minimal disruption to the production line.