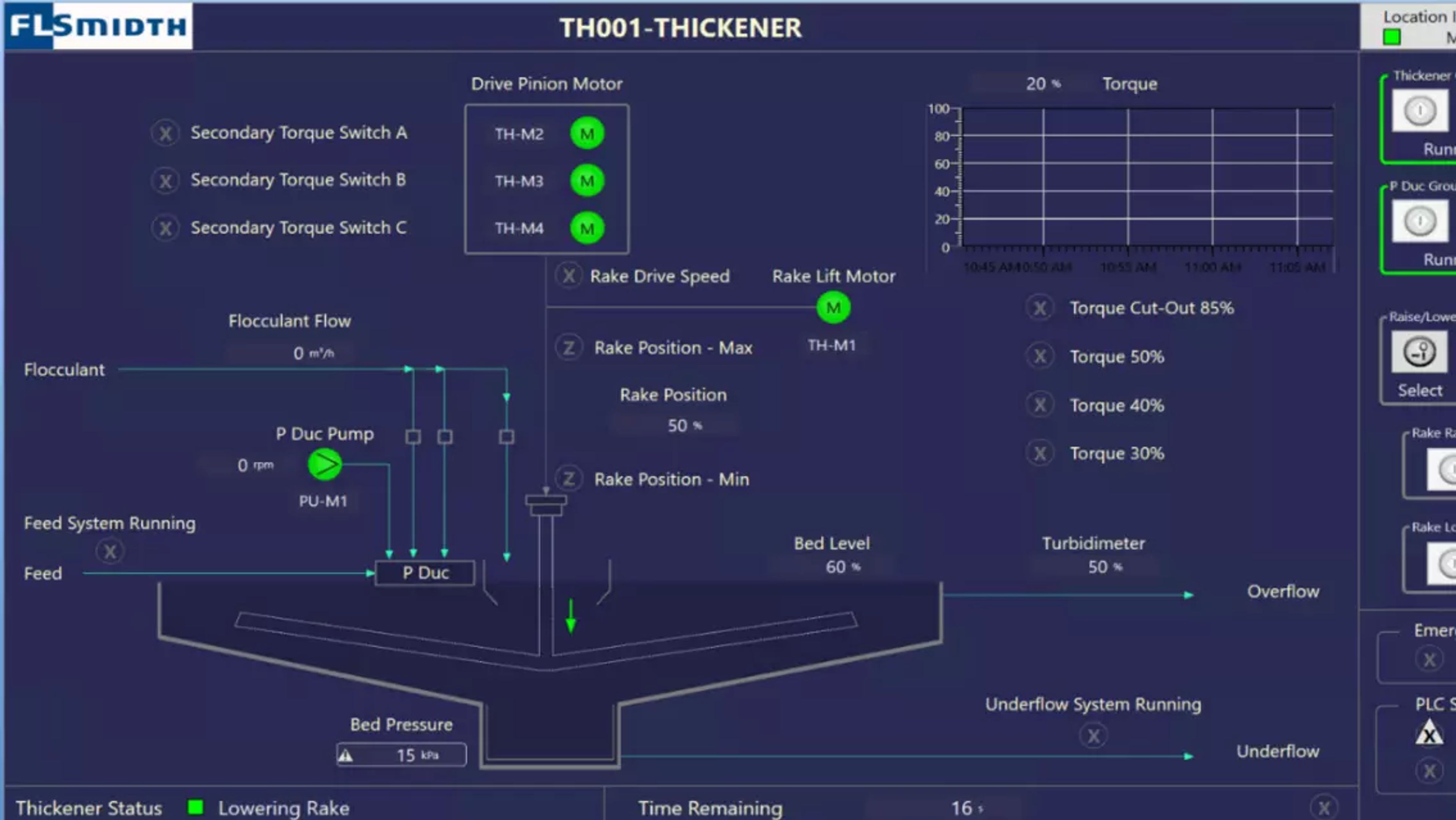

A control system that fits your operational needs

What we offer

A fast, flexible control system built for your business and for any machine

We know the landscape today is tougher than ever before for many businesses as they navigate high staff costs and often intense competition. To survive and thrive you need to manage your equipment as efficiently as possible, and you need control system software that allows you to commission equipment quickly and reduce downtime. Not only that, you need it to work with a range of hardware that may come from a variety of manufacturers. Our ECS™ Machine Control Solution is built with your needs in mind.

What is it?

Our machine control solution can control any machinery within your operation and be completely customised to suit your setting. With our software solution, you’ll be able to automate any machine to ensure you get the most out of its functionality, while eliminating the risk of operator error. This ensures greater efficiency and productivity within your plant.

Increased flexibility

Our software solution is designed to support a wide range of hardware, including products produced by major brands like Siemens, Schneider, Rockwell Automation and others. And, because it supports a variety of communication protocols, it will easily integrate with numerous other systems.

This makes life so much easier when it comes to upgrading systems as it’s not dependent on one particular supplier of hardware. With our machine control solution, you’ll have a control system that caters to your future needs, not just your present ones.

How can the ECS Machine Control Solution help my business?

Commissioning new equipment involves extensive testing and troubleshooting. Our machine control solution gives engineers the advanced tools and assistance they need to get the job done as quickly as possible.

And when faults occur, it is critical to establish the root cause as quickly as possible. That’s why our software solution provides tools taken straight from major control systems to support fast troubleshooting efforts. These advanced features give operators easy, efficient access to comprehensive information so they can quickly identify the problem.

The result is a digital, connected control system software solution that’s fast, flexible and minimises downtime, helping your operations to run at their peak.

A flexible control system for a wide range of hardware

We know you need to get equipment online quickly and minimise delays due to technical failures. And we know that your business has its own unique needs. That’s why we’ve built our ECS Machine Control Solution to be as flexible as possible, while giving you the tools you need to run your equipment efficiently.

Faster commissioning

With our software solution, your engineers will have access to advanced tools to help with testing and troubleshooting during commissioning. That helps speed up installation and allows you to get your equipment working productively, as quickly as possible.

Rapid troubleshooting

Your business can’t afford to have equipment offline for long periods due to equipment failures, so when something goes wrong you need to be able to identify the cause of the problem quickly. Our machine control solution is equipped with advanced features taken straight from our ECS/ControlCenter Software Platform. This ensures your engineers can find faults quickly and easily, and get everything back online fast.

Flexible applications

Our machine control solution is built with your business in mind. We’ve designed it to be flexible to your business needs so we’ve ensured it can be easily integrated with numerous hardware products to allow you to set up an individual configuration for any project.

Backed by FLSmidth know-how

When you choose FLSmidth, you get more than just a product. Everything we do is backed by our expert teams of engineers, project managers and support staff. We deliver on time and can upgrade your equipment and systems with little to no downtime to avoid production losses. With our ECS Machine Control Software you’ll also have access to around-the-clock support and troubleshooting from our teams so you can be confident we’ll always be there to help.

The fast, adaptable control system your business needs

Our ECS Machine Control Solution is so much more than a local control panel. We’ve built it to include many of the features of a full control system while making sure it can be adapted to your business needs.

The tools to act quickly

We’ve given you the tools you need to find faults quickly. Your operators will have quick access to comprehensive information like diagnostics and operation instructions to help them identify the problem and take action.

Industry best practices

Our ECS Machine Control Solution follows industry best practices to deliver a product that is standards compliant and consistent. It can be used to control and automate any machine in your plant, regardless of the manufacturer.

Easy to implement

Our software solution is factory programmed and requires only minor customisations on site, which allows you to commission equipment more quickly. We’ve also tested it to comply with specifications to further reduce commissioning time and the risk of damaging equipment.

Works with your needs

We’ve designed our machine control solution to easily integrate with numerous hardware products, such as programmable logic controllers (PLC’s) and input/output (I/O) modules, to allow you to set up an individual configuration specific to a project. This will make it easier for you to upgrade hardware in the future as you won’t be tied to just one manufacturer. Our software is compatible with controller brands like Siemens, Schneider, Rockwell Automation and others. If desired, it can also be integrated with your central control system to provide operators with critical alarms and status indications.

Easy to customise

Your business has its own unique needs and set-up. We get that, and we’ve built our machine control software solution to accommodate a wide range of customisations that your staff can apply using our intuitive user interfaces and comprehensive function libraries. You’ll also have access to remote programming assistance from our experts to help with any programming modifications.