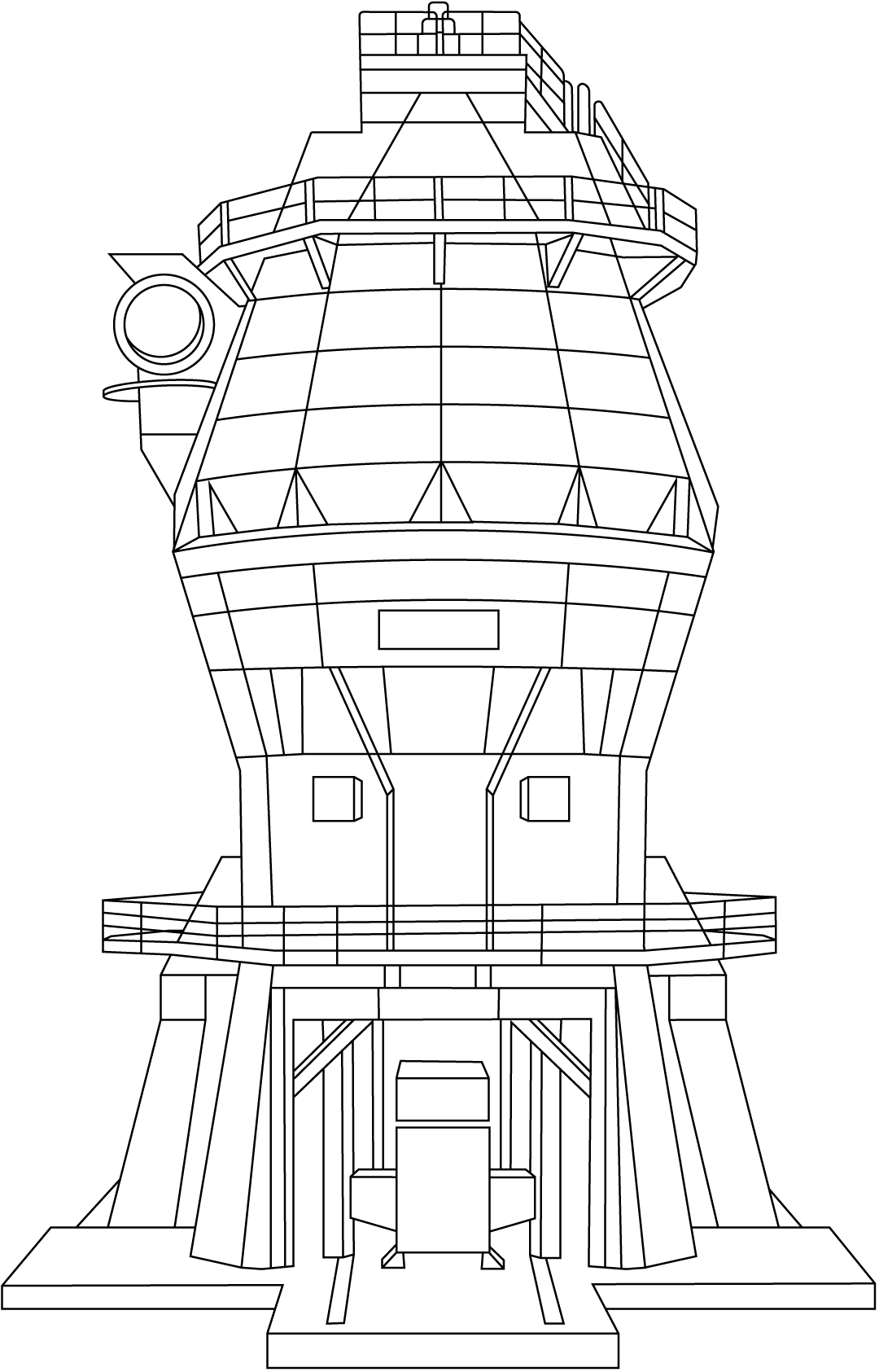

Maximise mill performance with a reliable maintenance strategy

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

What we offer

Straight-up services you can rely on to reduce vertical mill downtime

To increase the reliability and availability of your mill equipment, you need an effective preventative maintenance approach. Our comprehensive mill services help to identify and eliminate root causes of performance bottlenecks, so that you can prevent: Excessive downtime Hydraulic system failure Contaminated lubrication oil Oil leakage from rollers Repeated failures Vibrations

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)