Flow monitoring solutions to give your emissions analysis context

What we offer

Flow monitors that deliver real process insight

In order to gain real insight from monitoring process and stack emissions, you also need precise measurements of gas volume and velocity. Flow monitoring completes your emissions monitoring package, giving you all the data you need to comply with the reporting requirements of environmental legislation.

Reliable measurements of gas volume and gas velocity

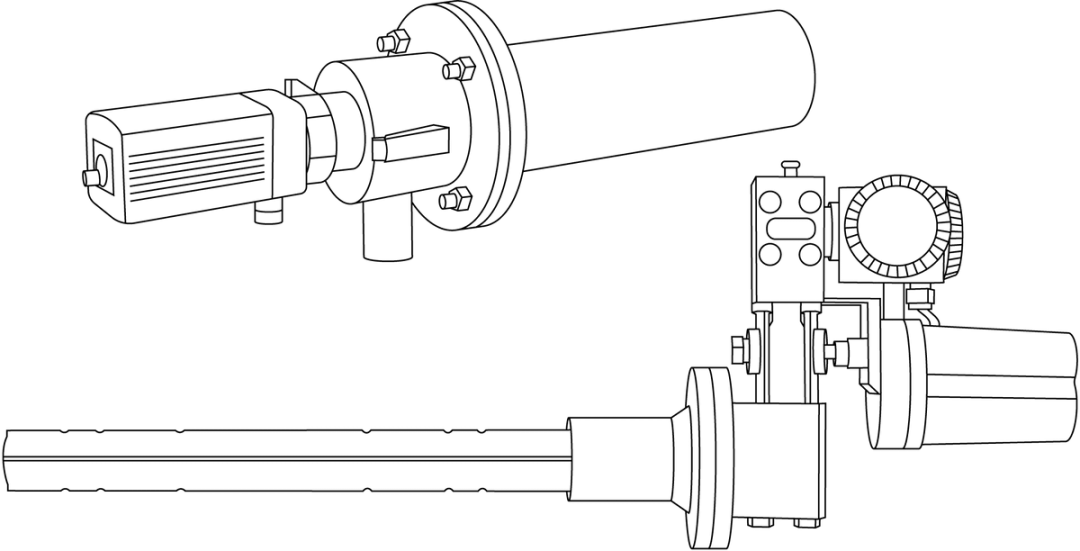

Durag D-FL 100

The D-FL 100 measuring system operates according to the differential pressure principle. The probe has two separate chambers between which the flow builds up a differential pressure. The evaluation unit determines the gas velocity and the volume flow (norm conditions or standard conditions) from the differential pressure, taking into account gas temperature and gas pressure. With this system, you can have continuous measurement of normal volume flow and gas velocity. And it can be operated with or without a control unit, via remote access with web interface. The flow monitor can also be used at high temperatures or high pressure and both for large or small stack cross-sections.

Durag D-FL 220

Measuring system for ultra-sonic measurement of flow and volume flow, especially for wet and aggressive gases. The measuring system works according to the acoustic transit time differential method. Two identical transducers mutually send and receive short ultrasonic pulses. The system calculates the precise gas velocity and volume from the direction-dependent transit time difference. This device provides reliable measurement of gas velocity even at high temperatures. There’s an automatic zero point and reference point control. And it can be operated remotely with web interface. As a non-contact system, it's subject to very little wear, giving you maximum availability and reliability.