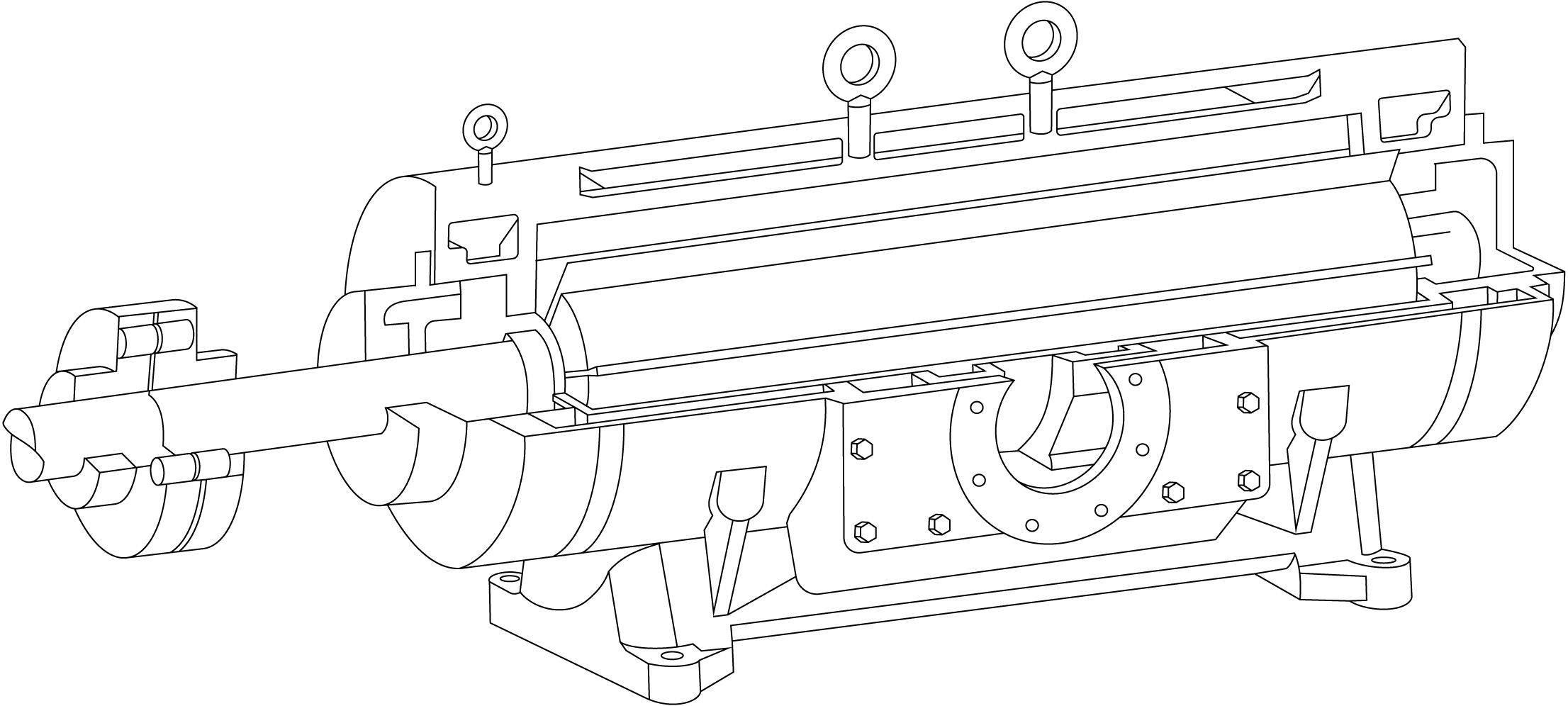

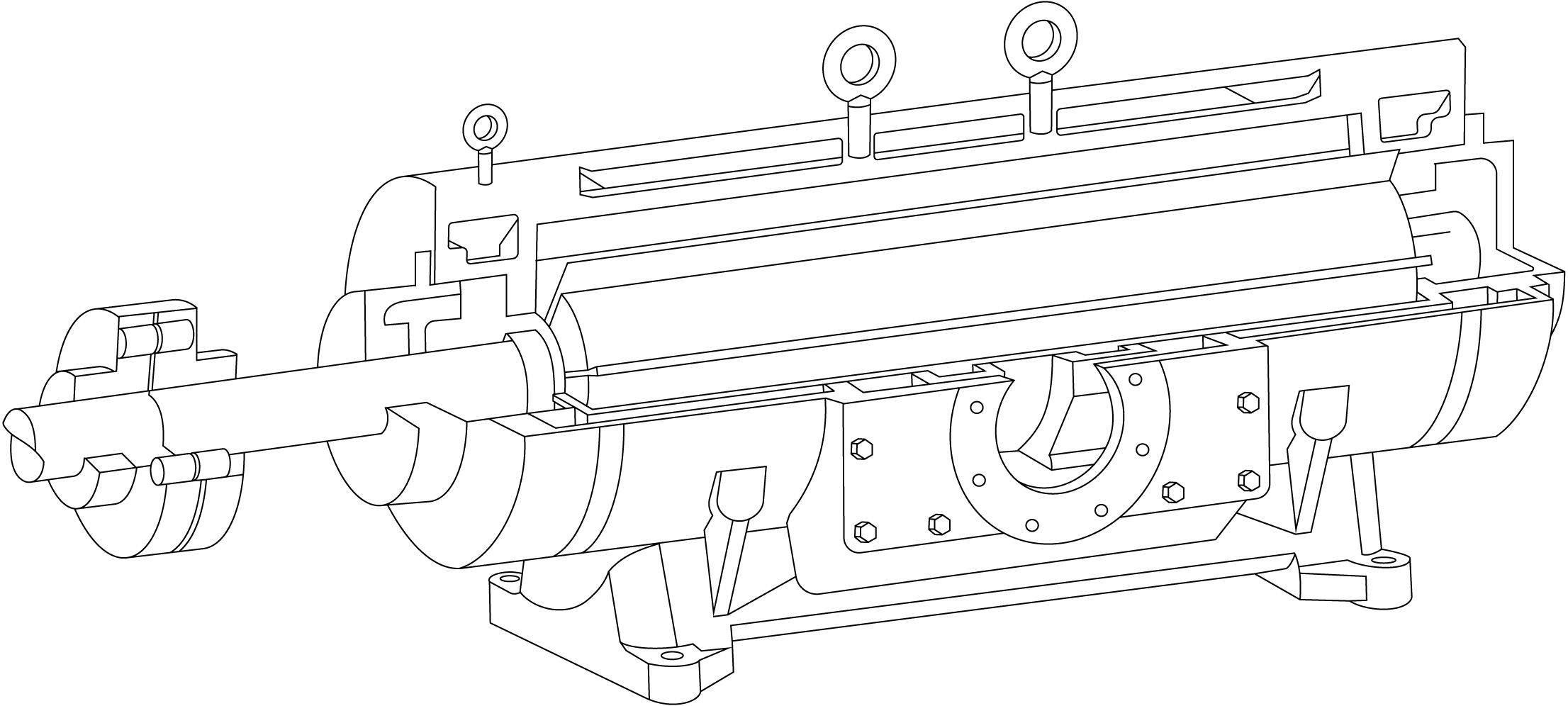

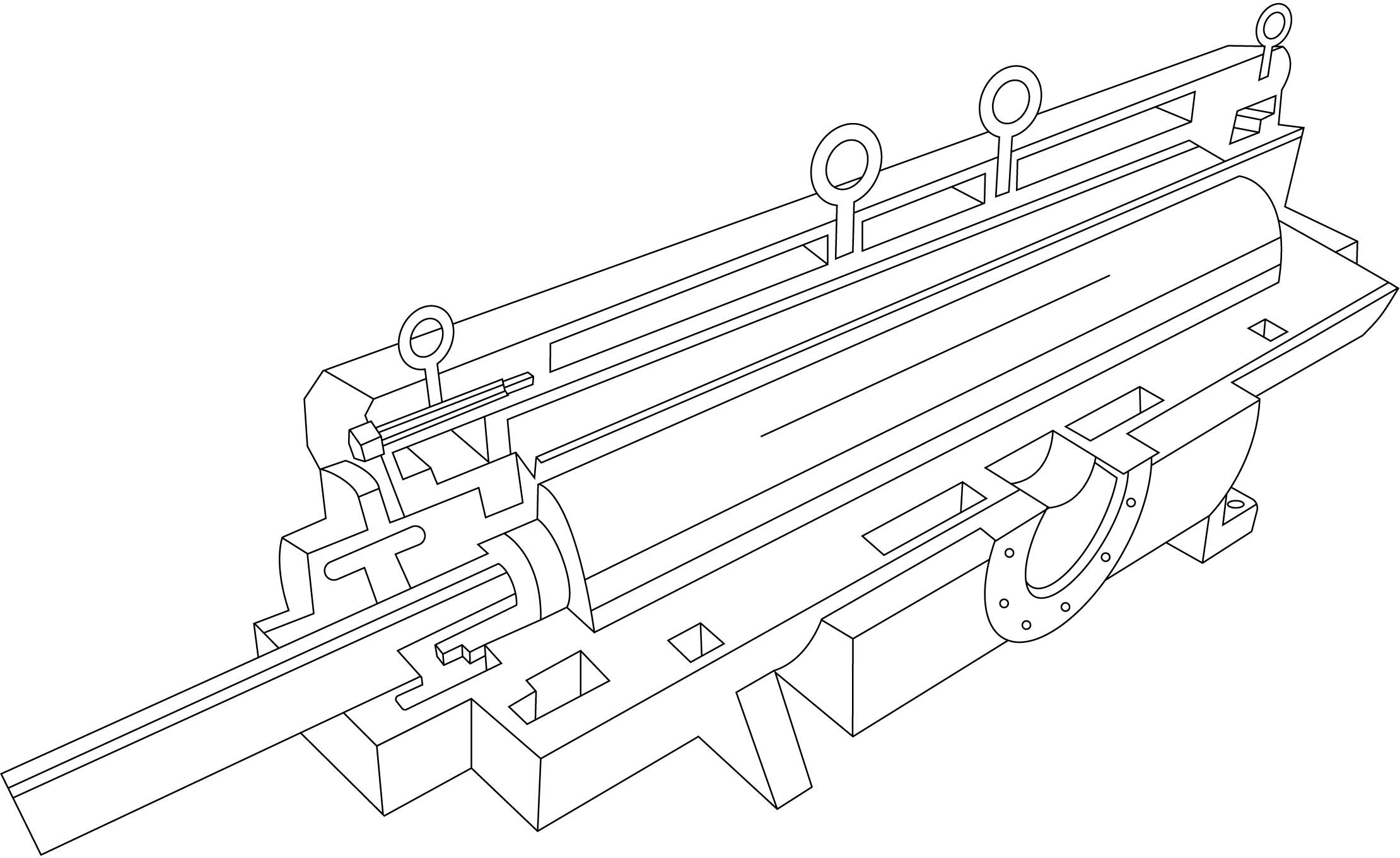

Carbon graphite compressor blades for Ful-Vane™ compressors

_Rotary_Vane_Gas_Compressor.png?w=1080&q=80&auto=format)

What we offer

Low maintenance, high performance

Compressor blades work hard. ‘Strong’ isn’t strong enough. At best, blade breakage is a costly maintenance item – at worst, it leads to catastrophic cylinder failure. To achieve true reliability, you need to think stronger. That’s why we use carbon graphite composite to make the B3000™ V2 compressor blades. With significantly greater strength and reduced weight, the B3000 V2 blades have up to four times the wear life of alternative blade materials under optimal compressor operating conditions. And, in the unlikely event of blade breakage, we guarantee the blades will not damage the cylinder bore. If they do, we’ll replace the cylinder free of charge.

Key benefits

Lasts up to 4x longer than alternate blades

Reduced operating costs, oil consumption and wear

Extends the life of the internal compressor components.

4-year protection warranty against blade defects.

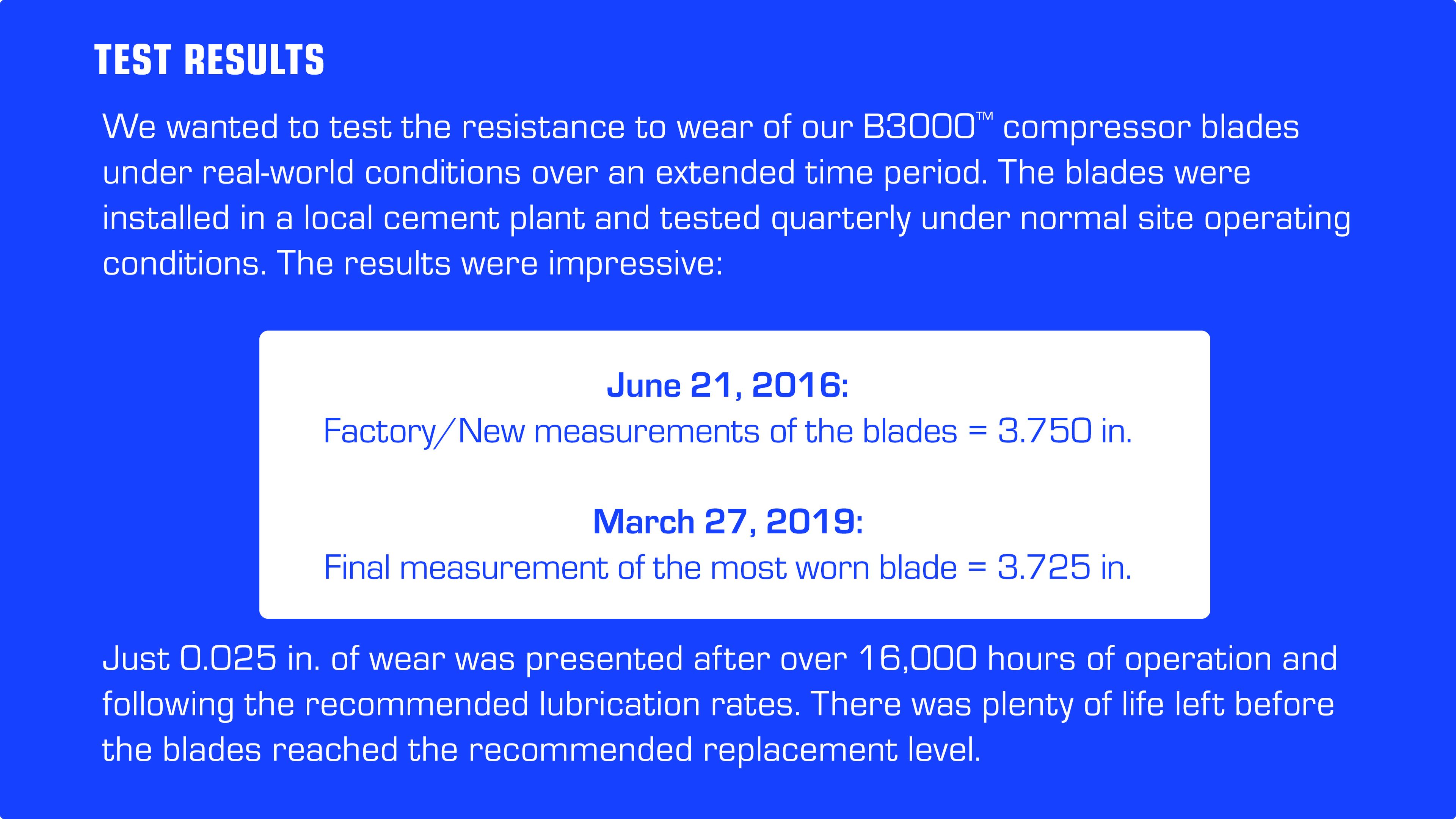

Proven in the field

We don’t just think B3000 ‘Black Velvet’ compressor blades are better than alternate blade types – their superiority has been proven in the field.

Less maintenance, lower cost

Our blades reduce cylinder bore corrugation by up to 50% compared to other blade materials – dramatically lowering maintenance time and costs.

Extremely abrasion-resistant

The carbon graphite composition is highly abrasion-resistant and allows for a maximum continuous operating temperature of up to 350°F (177°C).

Strong carbon graphite composite

Deformation and failure are unlikely due to the strong material properties.

Long life

The B3000 blades do not absorb moisture, so they avoid swelling, and have been engineered to withstand optimal storage conditions guaranteeing an extended shelf life.

Robert Jones III, Maintenance Manager, Buzzi Unicem, Stockertown Pennsylvania Cement Plant

B3000 V2 carbon graphite blades are available for all Ful-Vane™ compressors, exchange compressors, and cylinder assemblies.

_Rotary_Vane_Gas_Compressor.png?w=3840&q=80&auto=format)

_Rotary_Vane_Air_Compressor.png?w=3840&q=80&auto=format)