The process control platform that empowers productivity and sustainability

What we offer

Proven and adaptable process control

With more than 1900 active product and process control installations, the ECS/ControlCenter™ Platform is a trusted process control solution around the world. It’s a key component of our growing portfolio of digital solutions and services. The ECS/ControlCenter Software Platform is the digital heart of your operation: an advanced, reliable, adaptable and secure software platform that provides the foundation to control anything from machinery to full processes. It enables your business to get the most out of both your equipment and your operators, while simultaneously supporting greater sustainability and future productivity improvement.

Empower operators to reduce human error

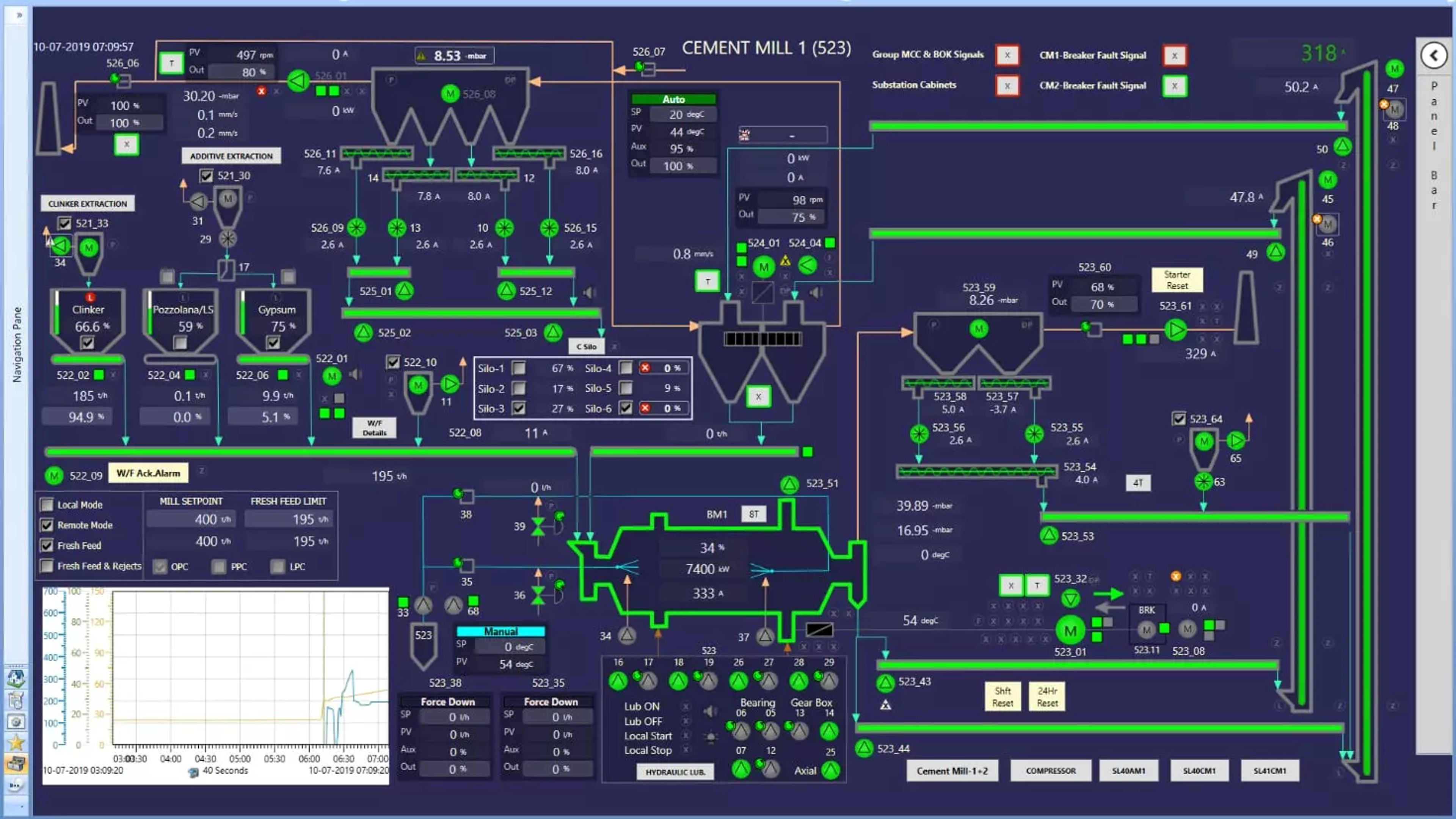

Across process industries, a significant proportion of unscheduled downtime is caused by operator error. Our aim is to prevent error by helping operators make good decisions. We are continuously focused on improving our operator interface to make it easy to understand and faster to navigate. Unnecessary information is filtered out, allowing the operator to see quickly where a reaction is required.

We are also working to integrate data analytics and machine learning technologies to help guide operators in their decision making, ensuring the ECS/ControlCenter Software Platform not only provides the best operator support now but into the future.

Finally, with our remote operation solution, we are enabling the sharing of knowledge, experience and best practice across sites by bringing operators together, under one roof. Sitting with each other. Learning from each other. Supporting each other. It is a human-centred approach to digital advances.

Keep your system running like new

To ensure your ECS/ControlCenter continues running as initially installed, our online condition monitoring service continuously monitors all your key equipment, including server PC(s), industrial network performance, PLC diagnostics, time synchronisation and client PC(s). Any problems that might affect your control solution are picked up by our intelligent algorithm, enabling you to act immediately to fix them – so nothing gets in the way of optimum performance.

Structured platform for digital optimisation

Digital optimisation is based on the provision of structured data. This is the fuel for advanced optimisation technologies, such as data analytics, machine learning and artificial intelligence. In combination with our ECS/ACESYS™ Control Library, the ECS/ControlCenter Software Solution provides that fuel. Designed to be hardware agnostic, our process control platform can be used with many different popular PLC brands, ensuring data of consistent quality and structure to empower your digital journey.

A software platform for your process control needs

Whether you are looking to control your FLSmidth equipment, a process area, your complete plant, including third-party machinery, the ECS/ControlCenter Solution is the software platform that makes it happen effectively. It is the basis for our three digital automation solutions – Process Control, Machine Control and Product Control – that are sure to cover your needs.

Safeguard control system uptime with online condition monitoring

We understand how important it is to keep your control system running. Without it, production grinds to a halt. And every stoppage wastes time, energy and money, impacting the productivity of your plant. If you choose to add our secure online condition monitoring services that provide insights to potential system problems, the ECS/ControlCenter Software Platform is protected against the risk of unplanned downtime.

Digitalization lies at the heart of business and sustainability success

Reduces costs through optimised productivity

The ECS/ControlCenter Software Solution improves productivity. By providing a platform for automation, it ensures equipment runs consistently at optimal conditions. By reducing operator error, it minimises unplanned downtime. This keeps throughput high, while boosting process efficiency and overall output. And with our proactive service module and advanced cyber security, we make sure that the control system itself is protected from unexpected stoppages. All of this means that you can be sure your plant is operating at its best, guaranteeing lowest cost per tonne of production. In short: we make sure you are in control to maximise your returns. We let you sleep well at night.

Enables progress toward sustainable operations

Digitalization is the enabler of sustainability. It lies at the core of our Green’26 strategy. How so? Digitalization allows processes to be optimised according to plant conditions. Energy can be used more efficiently, reducing the carbon intensity of production. Plant and equipment can be more finely controlled, reducing wear and tear – and the need for maintenance. And problems can be more quickly identified, limiting the risk of unplanned stoppages – and the waste of energy and production time on repeated start-ups. Meanwhile, provision for greater remote support – whether at commissioning, production or upgrade – reduces travel requirements to site and the environmental impacts that such travel entails.

Full lifecycle support from initial engineering to upgrade

Our solution provides support through the complete life cycle – from the initial choice of product to commissioning and onto our aftermarket services. These include remote user support and system updates, including cyber security patches, all provided by automation experts with years of experience in the cement industry. It’s a unique approach and means that, whatever stage of your process control journey you’re at, we can walk alongside and guide you to success.

Allows integration of third-party equipment and systems

Plants are rarely made up of equipment from a single supplier or equipment that is installed at the same time. Rather they grow organically with equipment and systems added and upgraded as needs arise. This requires a process control approach that is flexible enough to support a full range of equipment types and ages. The ECS/ControlCenter Software Platform can do this – even in situations where others said it was impossible. This was the case at Yanbu Cement, where we integrated two production lines running on PLCs from different vendors and older I/Os into a common control platform. This capability not only covers existing equipment but also future equipment upgrades and installations. Things that might not even been thought of yet. This means you’re not tied to any one supplier when you need to make that next change. You can choose whatever solution works best for you, safe in the knowledge that the ECS/ControlCenter Platform has it covered.

An advanced and adaptable digitalization platform

Our ECS/ControlCenter™ Platform has all of the functions you’d expect from a modern DCS system for effective operation at all plant levels. System and maintenance staff will enjoy the engineering benefits that come with our ACESYS Control Library. This world-class control standard enables ultra-fast engineering and maintenance of consistent plant-wide implementation. Meanwhile, detailed diagnostic data from the controller and electrical devices can be accessed directly in the system. Operators will be able to take faster and better-informed decisions with recent additions to the system, such as the combined trend and alarm view, advanced mimic symbols to support fast detection of upcoming limit violations, and root cause indications to quickly understand and eliminate stoppage. The ECS/ControlCenter™ Software Solution also includes an advanced trending tool with high data resolution and long-term data logging of all tags, both analogue and digital, even without a historian. Collaboration is made easy with the inbuilt electronic logbook and notification system, as well the ability to email snaps directly from the operator interface to relevant staff. This is possible from both onsite control room, as well as remote operation centres. When it comes to cyber security, the control center solution uses the latest technology based on Windows 11, Server 2022 and SQL Server 2022, with segmented network design, whitelisting-based malware protection (application control), and easy and fast back-up and restore tools. All of the above benefits can be delivered on your preferred control brand, as the ECS/ControlCenter™ Platform and ACESYS Control Library are designed to support a wide range of hardware from the major brands, such as Siemens, Schneider, Rockwell Automation and others. Controls from different brands can be combined seamlessly into the same system, maintaining consistent operating structure. This is particularly relevant if upgrading the control system on plants with multiple production lines, based on different platforms, into one system is desired.