Accurate weighing and dosing, however diverse the feed

In manufacturing processes, accuracy is key. Too much fuel and your process burns too hot. Not enough and you get incomplete combustion. In both situations, the impact falls on your product and your bottom line.

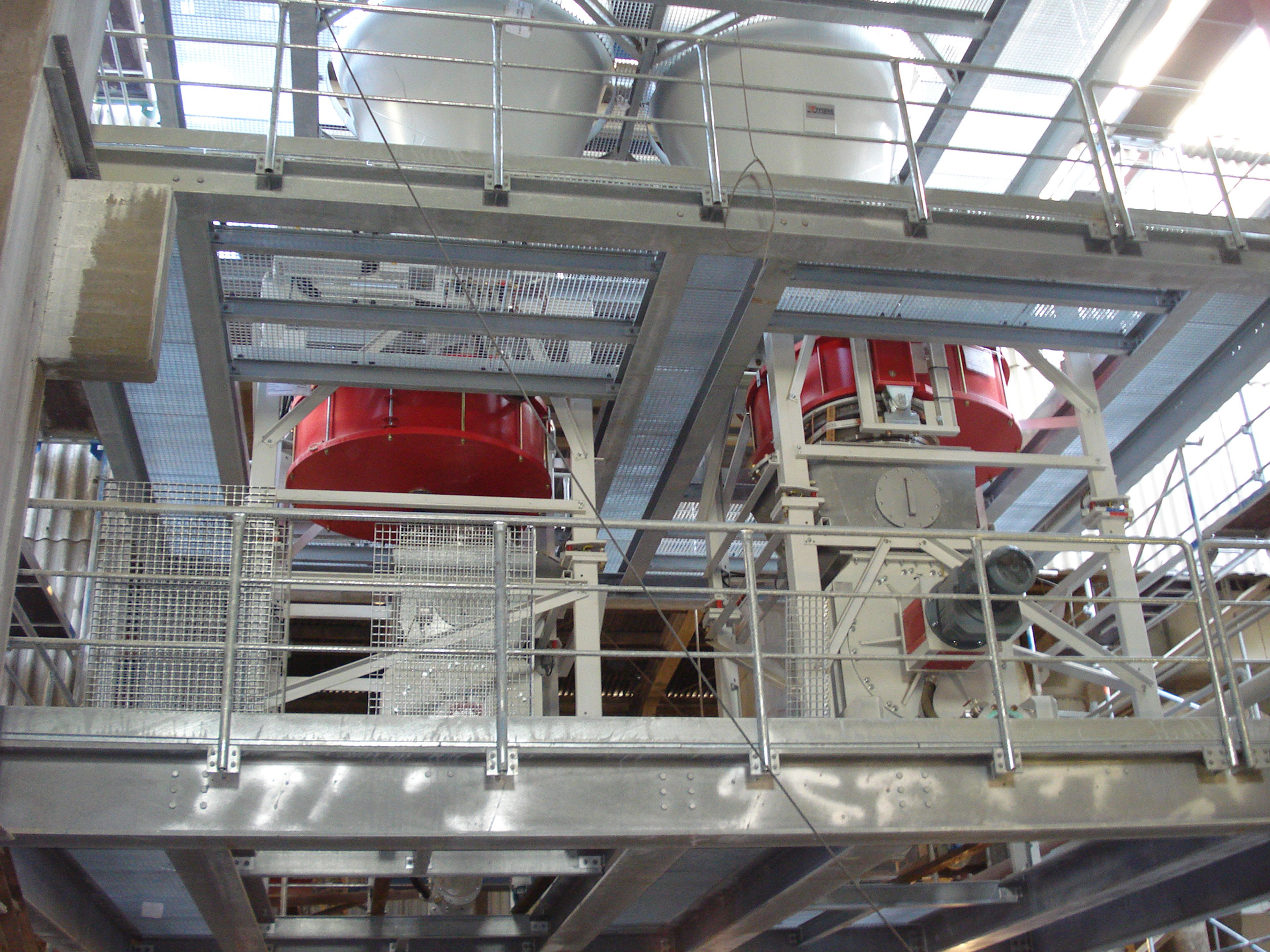

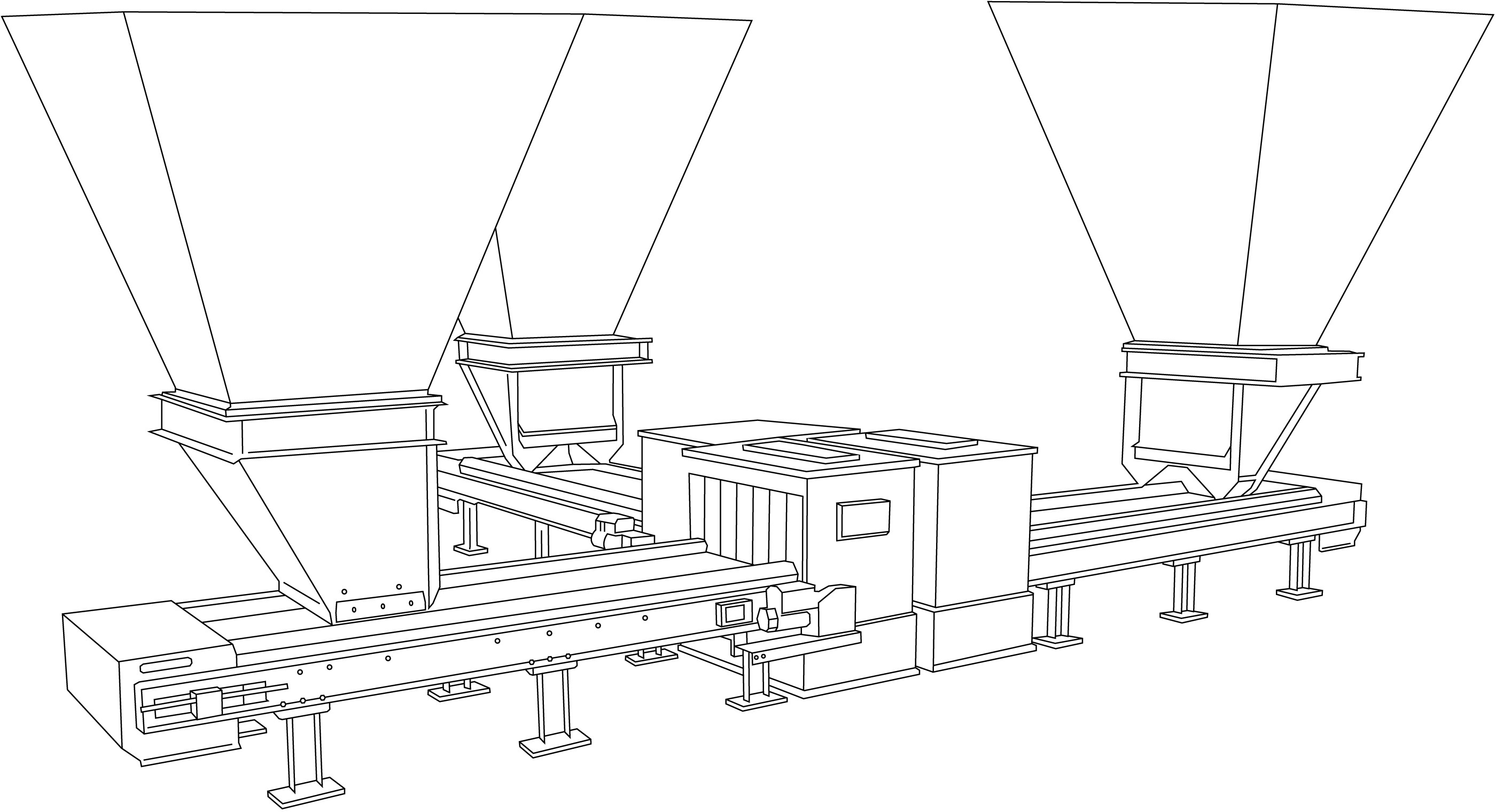

Weighing and dosing with the highest possible accuracy is a sure way to improve combustion and overall production quality. Our rotor and belt weighfeeders deliver a range of materials with the greatest precision thanks to our gravimetric weighing technology. Its success has been proven in all stages of production, from the raw mill to the finish mill, and in industries such as cement, iron and steel, fertilizer and thermal power plants.

PFISTER® patented rotor weighfeeders and belt weighfeeders measure materials such as coal and alternative fuels with the utmost precision, giving you a feed rate that is based on real data and not on time. Our gravimetric weighing technology compensates for the diversity in raw material and fuel feeds and adjusts the dosing speed accordingly.

.png?w=3840&q=80&auto=format)