What do you need from your gas analysis and emissions monitoring systems?

Reliability. Precision. Low-maintenance. High availability.

Over more than 40 years of supplying gas analysis and emissions monitoring equipment to diverse processing industries, we have listened to our customers. We understand your need.

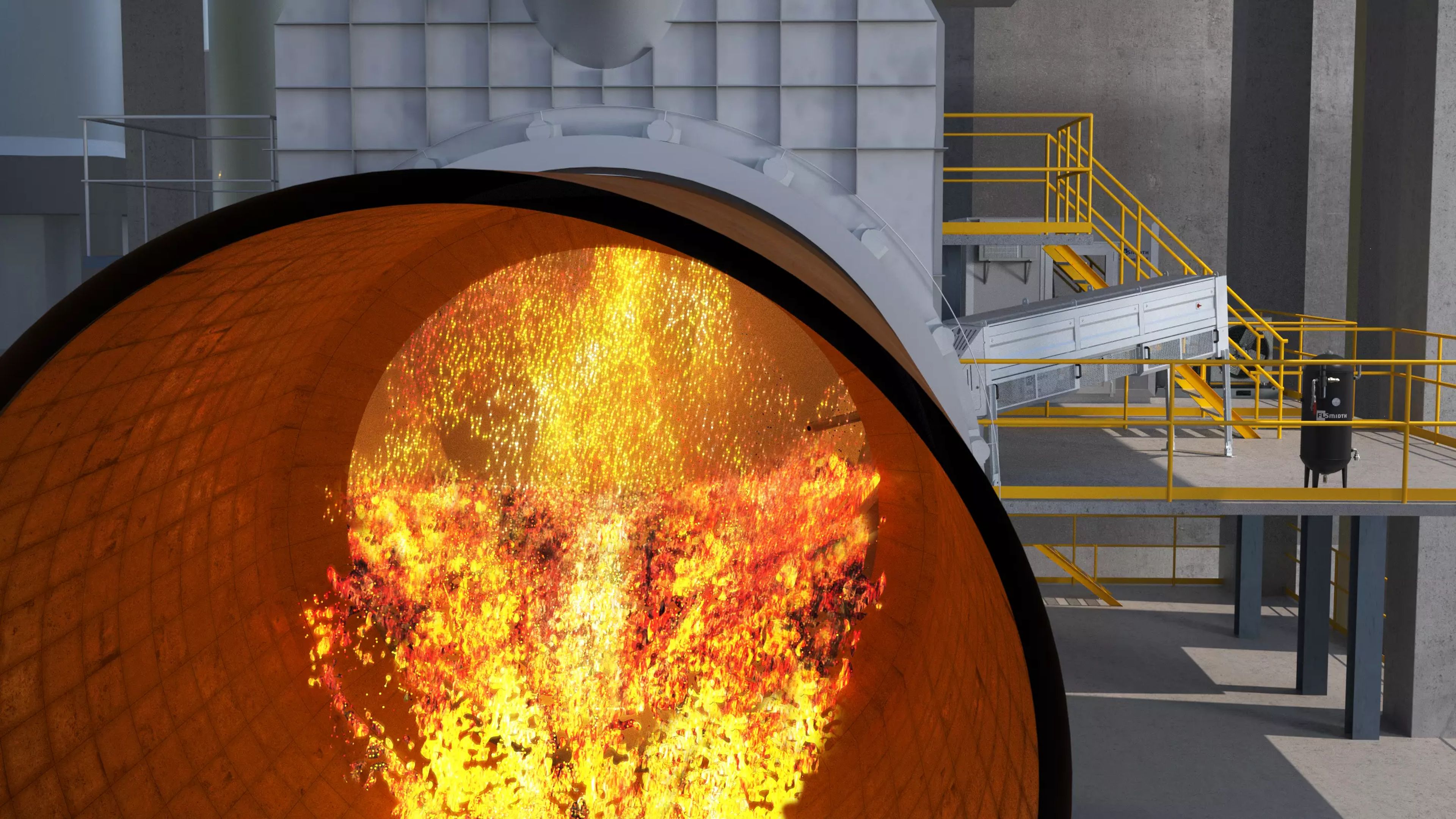

- Gas analysis solutions that can tell you precisely what’s going on in your process. Identifying potential threats to personnel and equipment safety. Detecting irregularities in your pyroprocess.

- Emissions monitoring equipment that works continuously. Turning raw data into insight. Helping you stay within regulatory compliance limits.

Your process is complex and the stakes have never been higher. Competition is fierce, costs are high and the penalty for exceeding emissions allowances is severe. But the good news is, the technology is up to speed. We can make you more efficient. We can help you lower costs. We can give you the insight you need to ensure exceedances do not happen.

Gas analysis systems that deliver

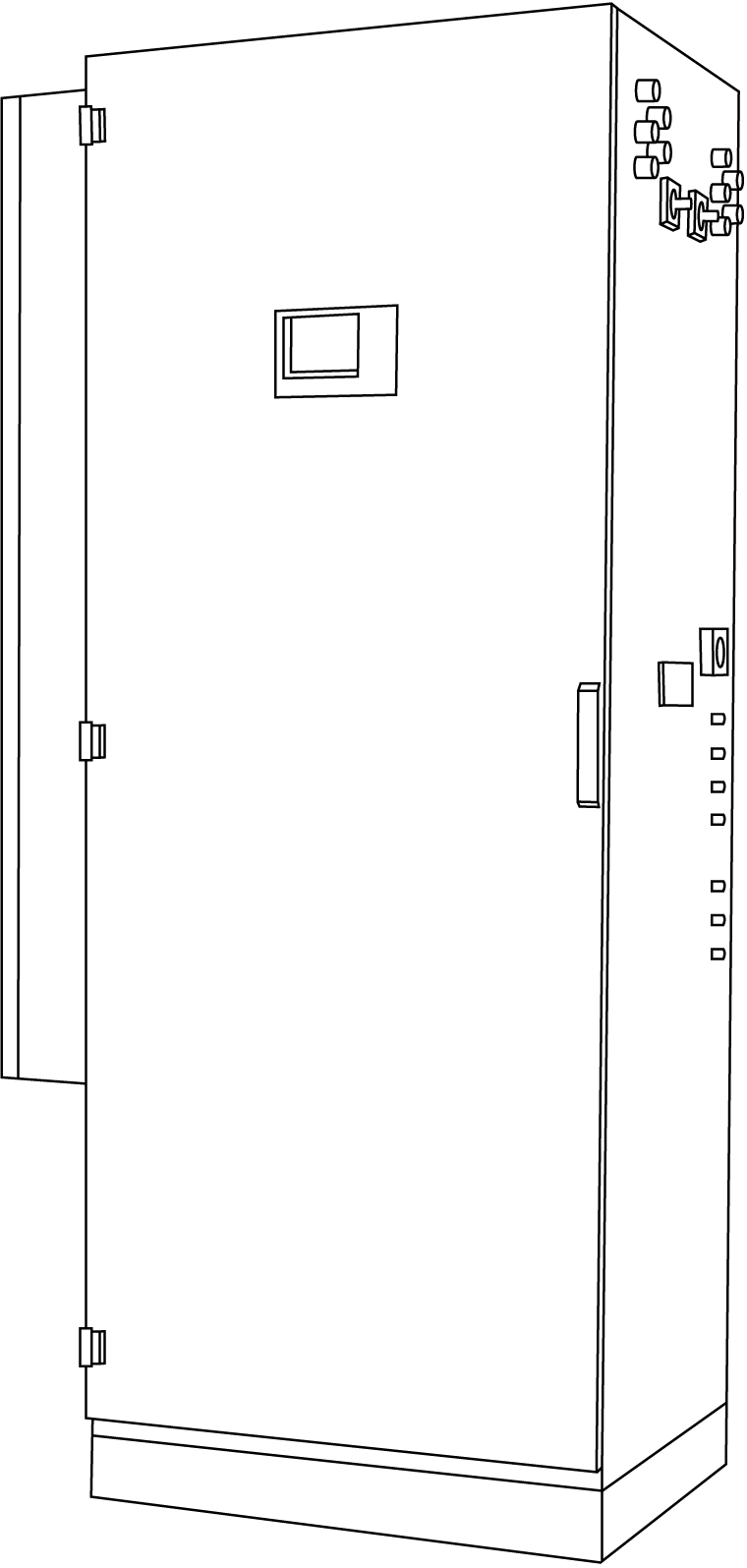

Every process is unique. Different raw materials. Different fuels. There is no one size fits all gas analysis system. Which is why we tailor every gas analysis solution to meet the specific customer need. We choose gas analysis instruments from among the best the industry has to offer. ABB. Siemens. Durag. NEO Monitors. Emerson. And we have our own solutions with unique capabilities. The patented KilnLoq probe is the preferred kiln probe across the global cement industry. Its sister product, the patented KilnLoq H/W, is built to withstand the harshest high-sulphur environments. The coal silo/filter probe offers reliable filter protection, while the double probe system is designed to eliminate downtime for cleaning. And we put all our gas conditioning equipment together into a GASloq system that is perfectly tailored to your needs, complete with everything you need to sample, condition and analyse process and emission gases.

Our aim?

To deliver the best possible gas analysis system that meets your needs. One that works in real life, not just in the lab, and never lets you down.

Emissions monitoring systems that tell the whole story

You need to know what’s coming out of the stack. Exhaust gases tell a story about what’s going in your process, and the implications that has on the whole system. But with ever more stringent environmental regulations coming into force around the globe, there are more reasons than ever to have a comprehensive overview of your emissions.

Our GASloq systems can be adapted to perfectly provide all the data you require. We can monitor the full range of gaseous emissions and particulate matter to generate environmental reports that are fit for purpose. Connect it with our ReportLoq environmental reporting system to carry out all the calculations required to provide your local authority with the relevant reports: short term average, long term average – whatever you need.

Process knowhow, built in

We understand the pressure you’re under to balance the needs of your delicate process with your responsibility to the communities in which you work. With more than 30 years’ experience in gas analysis and emissions monitoring, and many more decades spent working in cement and combustion industries, you can trust us to take care of this for you.

Our gas analysis and emissions monitoring business is based in Denmark, where we test and document all of our solutions in accordance with our quality management system. We have a wealth of process knowhow, providing gas analysis and emissions monitoring solutions around the world for a multitude of applications:

- Kiln control and optimisation;

- Filter protection;

- Emissions monitoring;

- Emissions reporting; and

- Safety measurements, etc.

Service technicians are available worldwide to assist with your process. And they can draw on the resources of the global FLSmidth Cement group for further expertise if required.

.png?w=3840&q=80&auto=format)