Superior sample preparation with QCX® Dosing, Cleaning and Fusing (DCF) Units

What we offer

QCX DCF automation – the simple and safe solution for sample fusion

X-ray fluorescence (XRF) analysis analyses fused bead samples to rapidly and accurately measure the chemical composition of raw materials and ores. Errors can cause production disruption and poor quality output, so ensuring you prepare your samples correctly is a must. Our fusion technology has been developed over many years to reliably prepare fused beads with precisely weighed samples and fluxes. This improves the sample reproducibility and ensures a high analytical quality. In fact, our fusion technology is so reliable, that over the last 15 years, we have seen many laboratories using our automated units as their sole method for preparing samples for XRF analysis. We engineer our equipment not only to improve the quality of your operations, but also to boost your productivity. That’s why we’ve designed the QCX Dosing, Cleaning and Fusing (DCF) units to give you the ultimate in convenience – handling the whole process in one low-maintenance machine: Dosing, weighing and mixing of flux and sample Fusion Cleaning of the crucibles By automating the entire sample fusion process, these cost-effective units pay for themselves. They reduce the need for repetitive, labour-intensive work, leaving your operators free to focus on more complicated tasks. Their high throughput capacity increases your productivity. And automatic dosing minimises consumable waste, reducing your costs even further.

Trouble-free sample preparation with fully automated DCF units

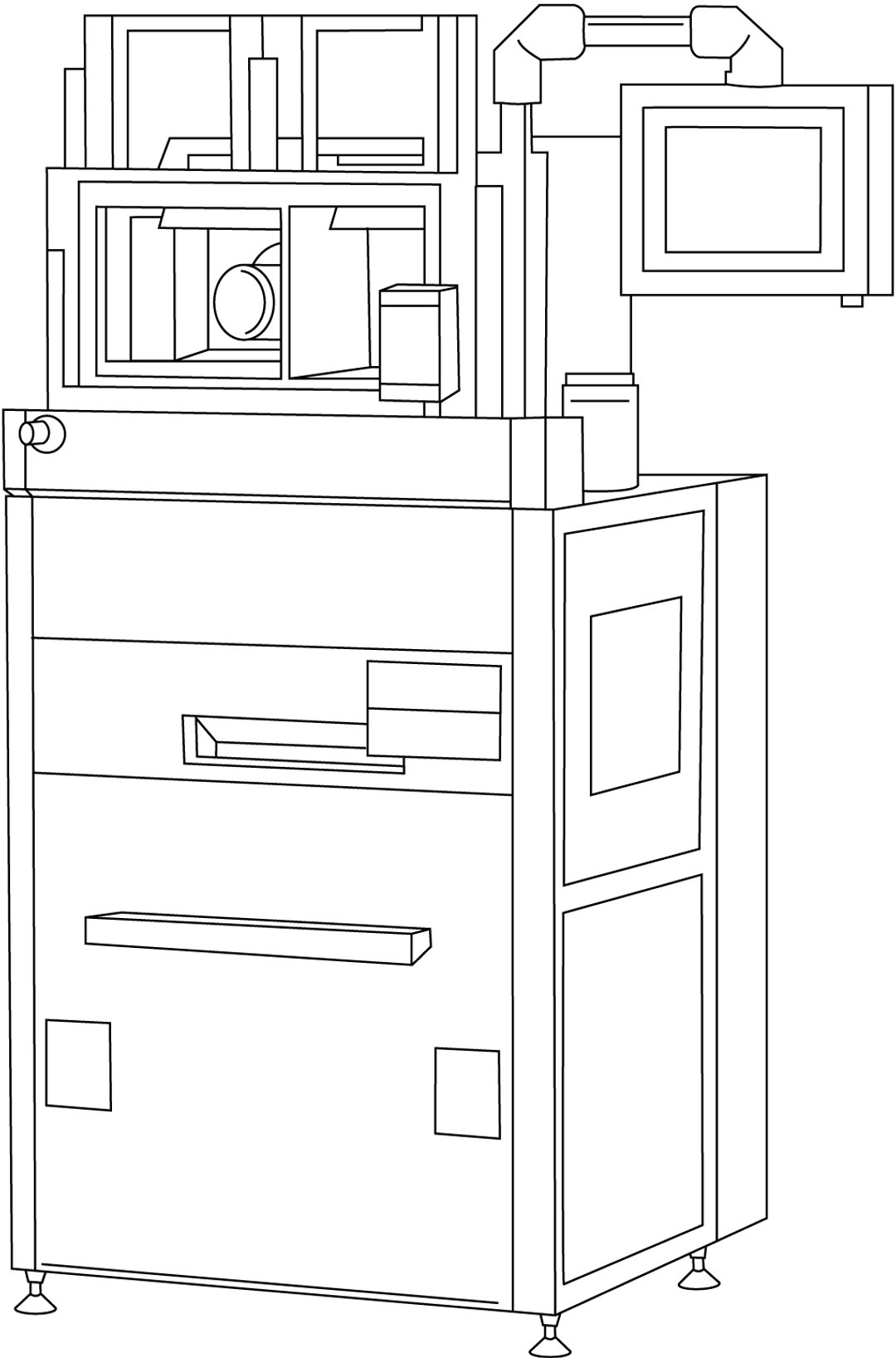

QCX DCF820 Dosing, Cleaning and Fusing Unit

Highly accurate With increasing demands on laboratories, there is no room for error in sample preparation. A key advantage of the DCF820 is its highly accurate, automated dosing and weighing function. The unit achieves dilution ratios with an accuracy of +/- 0.15%. Dilution ratio and flux type can be adjusted from sample to sample, according to recipe. Convenient and consistent The fully automated machine prepares fused beads for XRF analysis at a typical rate of eight beads per hour. It precisely manages the dosing of the flux and the material sample, casts the fused beads, and cleans the crucibles. This process happens in three functionally-separated sections: Top section – an integrated muffle furnace and linear manipulator Middle section – a high-precision flux and sample dosing station operating at 0.001 g precision levels. Lower section – a linear manipulator, ultrasonic bath and rinsing/drying station to clean the crucibles returned from the fusion process. The furnace can store up to 32 unique fusion programs, giving you effortless control.

QCX DCF830 Dosing, Cleaning and Fusing Unit

Fast and efficient If you require high sample throughput, the DCF830 typically produces fused beads at a rate of 16 beads per hour. With twice the output of our smaller QCX DCF820 model, the QCX DCF830 is the ideal choice for high capacity laboratories. Reliable results You can rely on the QCX DCF830 for consistent sample preparation. Samples are mixed with the flux with dilution ratio accuracy ranging from +/- 0.15% (precise dosing) to +/- 0.75% (rapid dosing). The unit features two muffle furnaces able to handle temperatures between 300°C and 1200°C. The crucibles are cleaned automatically using a heated ultrasonic bath with a cleaning reagent followed by washing with tap or distilled water, and hot air drying. This thorough, in-built cleaning mechanism reduces the chances of cross-contamination. Cost-effective The QCX DCF830 is suitable for an automated laboratory where containers and samples are handled by a robot or manipulator. Our fully automated system improves productivity in your laboratory. Staff are no longer required to perform the repetitive, manual handling needed with traditional methods, and can focus on higher-level tasks, saving you time and money. And sample throughput is increased, reducing your cost per analysis.