Complete pyroprocessing solutions that lower your operating costs

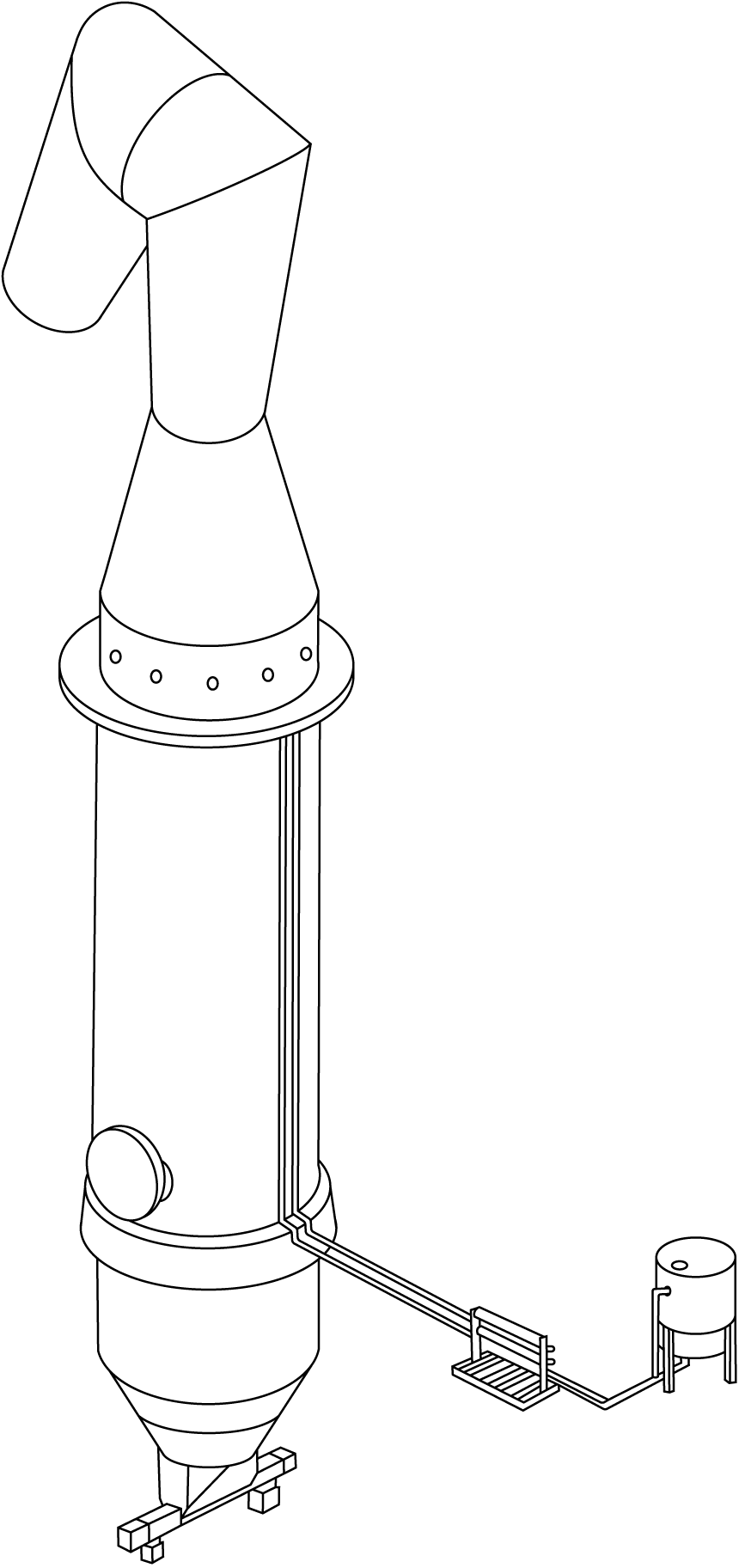

The pyroprocessing unit is central to a plant’s efficiency and uptime. That’s why so many producers choose a pyroprocessing system from FLSmidth Cement.

Our preheater/calciner systems have the lowest NOx and CO emissions in the industry. Not only that, but their simple design and highly efficient operation make them the industry standard. All our preheater/calciner systems can be tailored to your specific raw materials, fuels and emission requirements.

The world’s best rotary kilns

Our rotary kilns are suited to even the most challenging raw materials and fuels and they continue to deliver at the highest production rates. They come in 2-base and 3-base versions, and both offer proven operational reliability and durability for continuous performance with low maintenance costs.

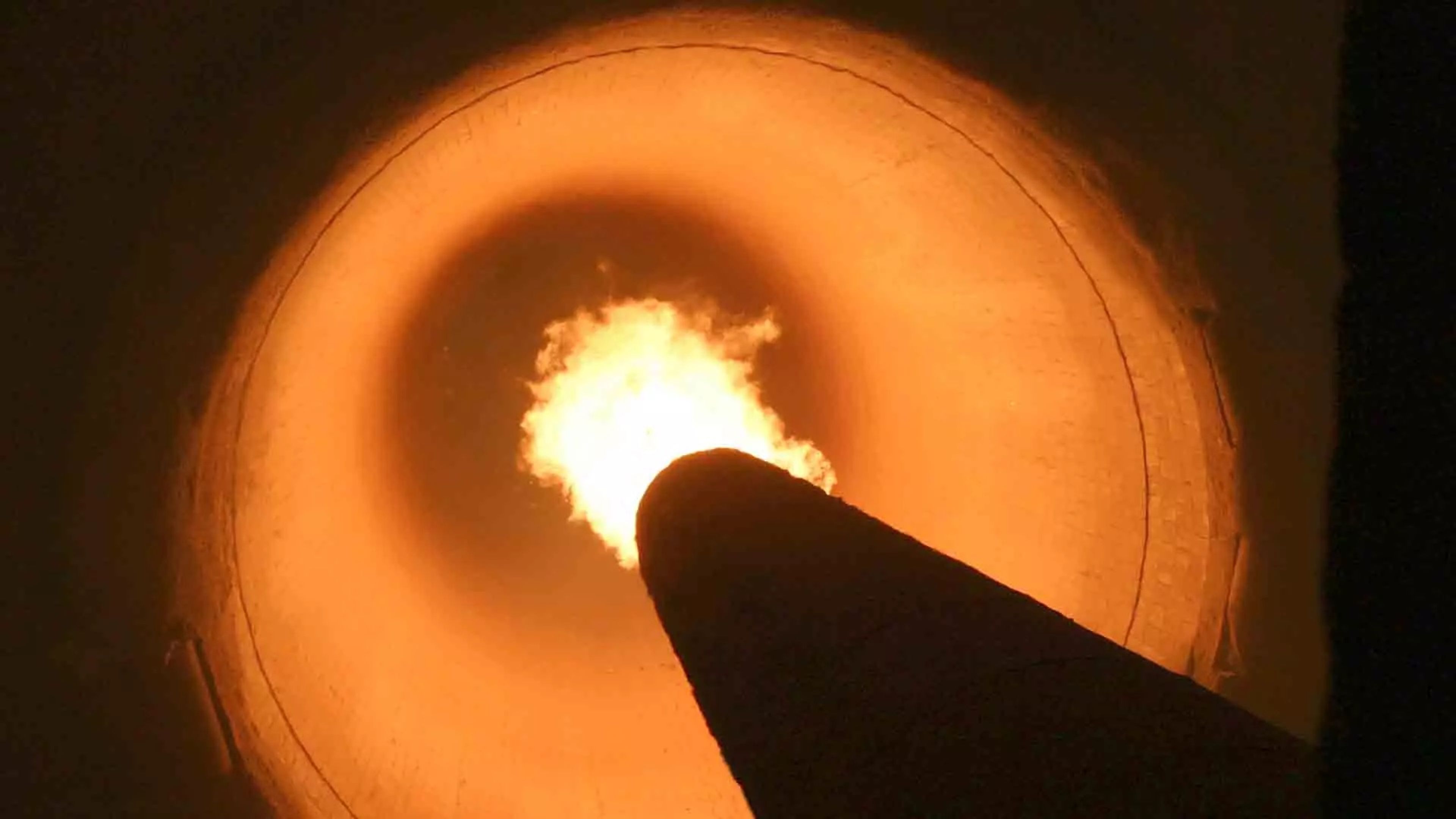

Burn almost anything to lower your fuel costs

Integrated with your preheater/calciner systems, the HOTDISC® Combustion Device enables you to burn almost any alternative fuel – from wet powders to tractor tyres. This gives you the ability to lower your fuel costs by choosing from a wide range of alternative fuel options and suppliers.

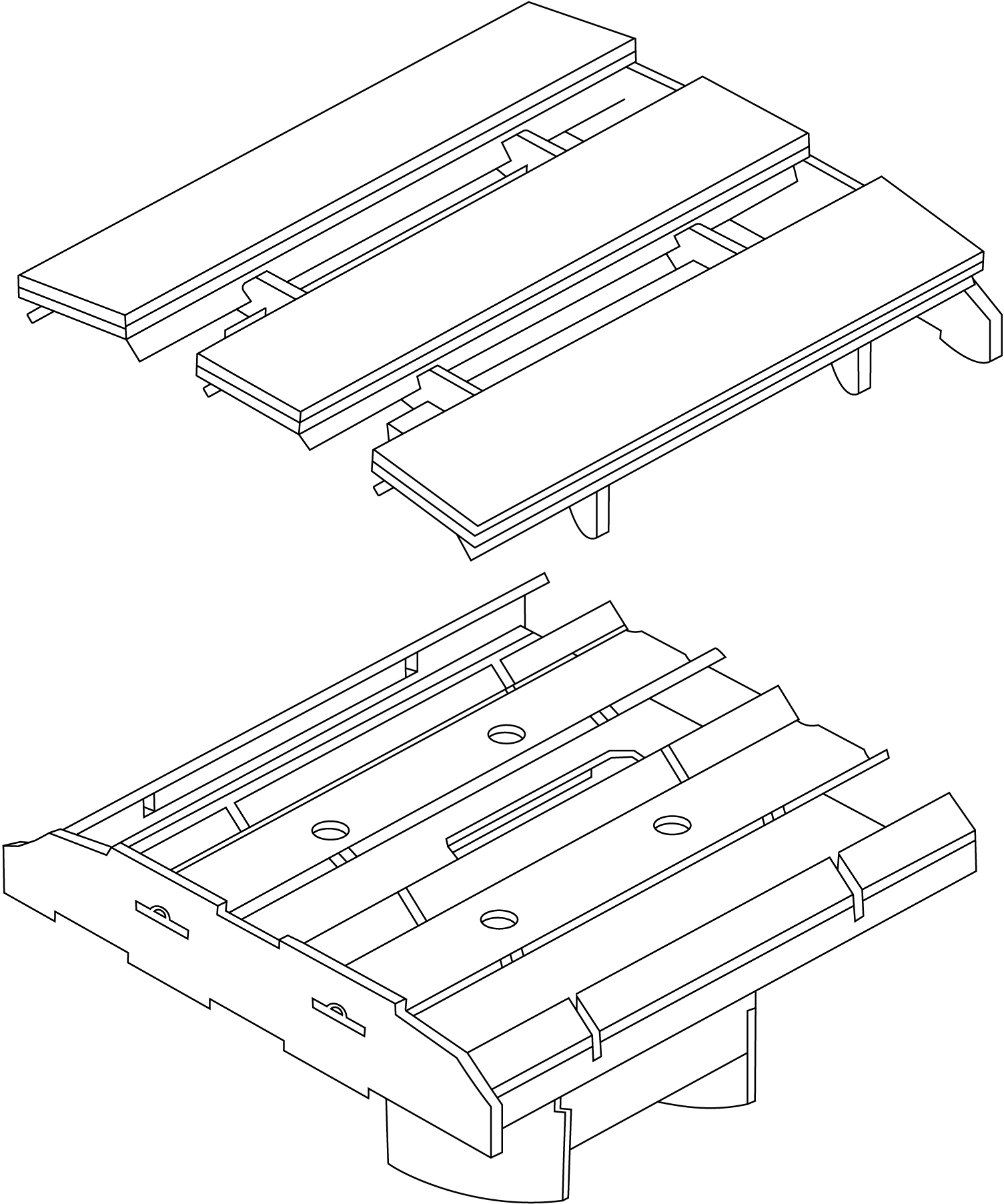

Cooling systems that cut your costs

When things get hot, you need a cooler that won’t let you down. Our Cross-Bar® Cooler gives you reliable long-term performance, efficient heat recuperation and high uptime.

All the data you need

Our high-temperature gas analysis systems collect the data you need to optimise your kiln’s combustion and production process, including increased production, reduced fuel and power consumption and improved clinker quality.

Let our experience make the difference

Whether you are working on a new production line or retrofitting an existing plant, our specialists can ensure your entire pyroprocessing system is optimised to your plant’s specific requirements – to help improve your overall efficiency and economy.

_and_Multi-Movable_Cross-Bar_coolers.png?w=3840&q=80&auto=format)

.png?w=3840&q=80&auto=format)