Hi-Chrome Wear Segments offer a long-lasting, sustainable wear solution

What we offer

Best fit in installed products

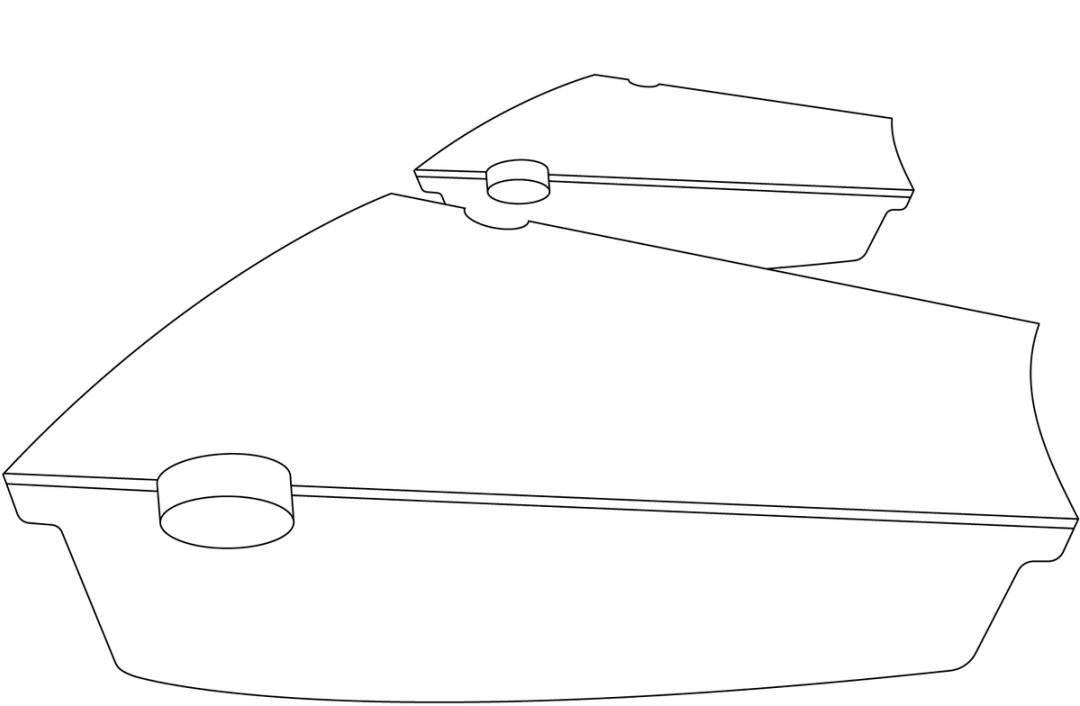

Hi-Chrome Wear Segments for vertical roller mills are made by us for our mills, thus, the guarantee for best fit in installed products.

The optimal wear solution for your FLSmidth vertical roller mill

Hi-Chrome Wear Segments are a long-lasting and flexible solution to wear protection needs. The segments are recyclable at end of life, making them the sustainability option compared to alternatives.

High quality

The uniform microstructure of our Hi-Chrome Wear Segments ensures that all segments comply to our high standards. But we don’t just assume that. Each Hi-Chrome segment is individually checked against FLSmidth standards before installation. And because they are made by us for our own vertical roller mills, you can be sure that they are made to measure, perfectly fitting original tolerances in installed products, and ensuring optimal wear resistance.

Flexible

Hi-Chrome wear parts also offer a re-usable wear solution. Segments are suitable for repeated hardfacing and can be refurbished in-situ to bring them back to the correct surface profile. This keeps downtime to minimum and ensures the continued high performance of your FLSmidth vertical roller mill. Hi-Chrome Wear Segments can also be reversed and re-welded on some applications of the rollers, essentially doubling the life of the segments.

Sustainable

Hi-Chrome segments offer long life – even in highly abrasive conditions. But when they do finally reach the end of their usability, they can be recycled. This makes them a more sustainable option than segments made from ceramic composite materials, which are difficult to re-use and are often sent to landfill when they reach the end of their life.