Precise, reliable dosing of fine-grained and powdered materials

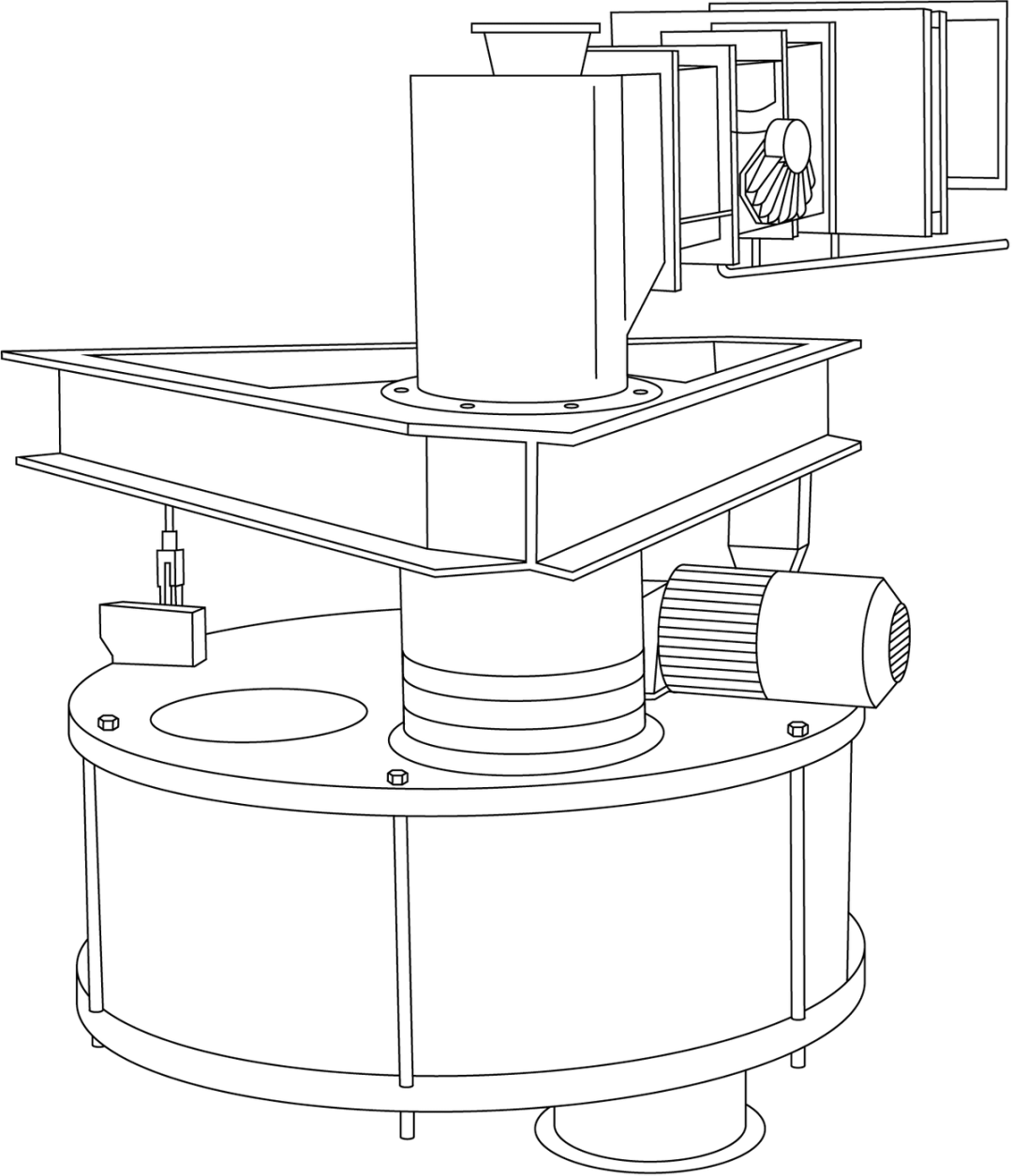

PFISTER® FRW 5 series

Gravimetric feeding and dosing. Accurate and easy to operate.

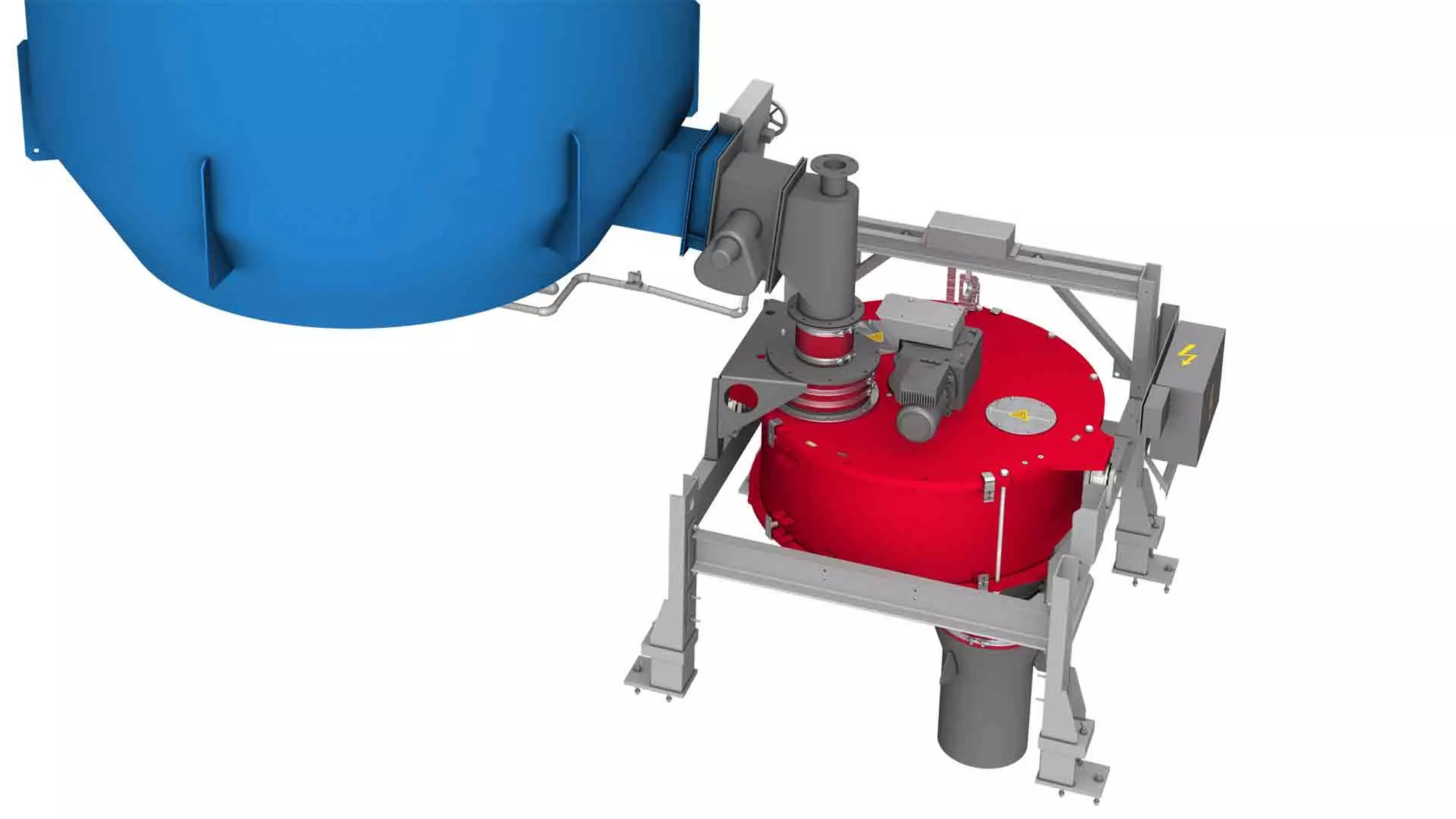

When it comes to precise processes like cement manufacturing, the accuracy of your feeding and dosing systems is crucial. The strength of the final product is dependent on getting the mix just right. And it’s not just product quality at stake. When dosing is not consistent, the efficiency and profitability of your process is also impacted. The PFISTER FRW Rotor Weighfeeder is designed for highly accurate gravimetric feeding and dosing of fine-grained and powdered bulk materials, such as raw meal, limestone, hydrated lime, fly ash or bypass dust. The advanced weighing electronics enable truly consistent feed rates with the utmost reliability. If you combine the rotor weighfeeder with a feed bin, you also have the option of online calibration to ensure reproducible weighing data. As the cement industry increasingly pursues a more environmentally-friendly process, the addition of waste materials such as fly ash or slag to the finish mill will make an important contribution. Accurate dosing will maintain cement strengths while reducing costs and CO2 emissions – and putting your cement plant on the path to MissionZero

Your application deserves a tailor-made dosing solution

FRW Rotor Weighfeeder is typically used in kiln feeding or finish mill feed applications, for cement blending. But what do you need? We will always work with you to determine the best solution for your application.

- Feed rates from 0 – 1000 t/h

- Rotary valve or flow control gate; as pre-feeding device

- Cabinet or field control solutions available

- Improved rotor design with sealings to avoid any blockage of the system and material flushing

- Suitable for installations in low or high ambient temperature environment.

High accuracy. Low maintenance. Reliably consistent.

Reliable and consistent. Two key attributes of any plant equipment, but particularly true for applications like this. You need to be able to trust your rotor weighfeeder to dose accurately in the long-term as well as over short time periods. For dosing to be consistent and repeatable, whatever you are dosing. Whether it is raw meal to the kiln or off-spec cement to the finish mill, the FRW Rotor Weighfeeder accurately weighs as it doses for unbeatable precision. High-temperature options are also available where needed. With the use of ProsCon® advanced weighing electronics, dosing is controlled proactively for continuous accuracy – short-term, long-term, all the time. And what’s more, by combining the PFISTER Rotor Weighfeeder with a pre-hopper equipped with load cells, you can calibrate the system online to ensure repeatable data output.

Simple and modular design

Your operation is complex enough. You don’t need any additional complications. That’s why we design simplicity into our systems – simple maintenance, simple operation. The rotor weighfeeder has minimal and slow- moving parts to ensure optimal performance. The modular design makes for easy installation and even easier maintenance. Everything that needs to be maintained can be accessed from the outside, making it both simple and safe. And there’s no tricky cleaning to do and no mechanical parts replacement necessary. We’ve also improved the patented rotor design to prevent blockages, ensuring you really can just install it and forget about it.

Remote support

Opt for the PFISTER® Remote Support Package and you are guaranteed expert support whenever you need it. Full remote feeder access and remote error analysis is available with experienced feeder specialists who have extensive technical and process knowhow.

How does the PFISTER® FRW Rotor Weighfeeder work?

It is typically used together with a pre-hopper equipped with load cells to enable online calibration. In a standard kiln feed installation, raw meal is transported from the silo into this pre-hopper, where it is weighed. calibrated. From the pre-hopper, the material is fed to the rotor weighfeeder via an electro-pneumatic flow control gate. The speed of the rotor is controlled by the ProsCon® advanced weighing electronics, which controls the speed inverse to the load, ensuring a consistent feed rate. The straightforward design is made even simpler by the fact that it is modular, making for easy installation and maintenance.