Access expert maintenance, troubleshooting and repairs

What we offer

Optimise performance with online condition monitoring services for kilns

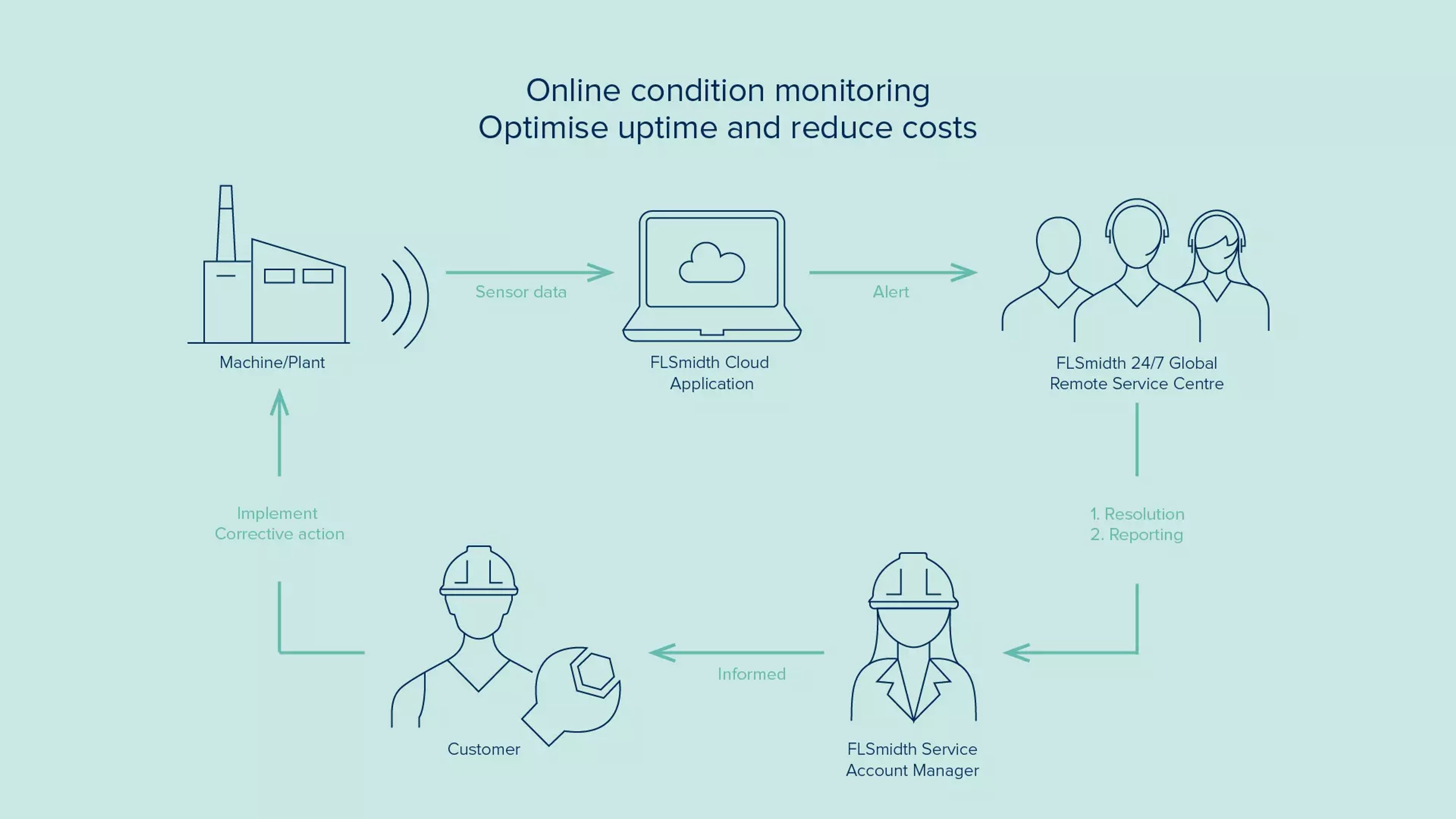

The kiln is the heart of your plant – but are you looking after it properly? Most kilns are operated with a few isolated sensors and an inspection every 2 – 3 years. That simply doesn’t give you enough information to optimise performance and be proactive with kiln maintenance. You need 24/7 online condition monitoring services. With online condition monitoring services for kilns, you have the ability to gather data and insights that were previously unavailable through third-party inspections. It’s the difference between treating the same symptoms over and over and identifying the root cause of kiln problems. A difference that can save you significant time and money. Data plus expertise: our services are focused on coupling data with expert oversight. We don’t just install sensors and leave you to it – the experts at our 24/7 Global Remote Service Center help interpret the data and provide actionable insights so you can optimise kiln performance and be proactive with kiln maintenance.

The online condition monitoring services for kilns come in two packages – Level I and Level II

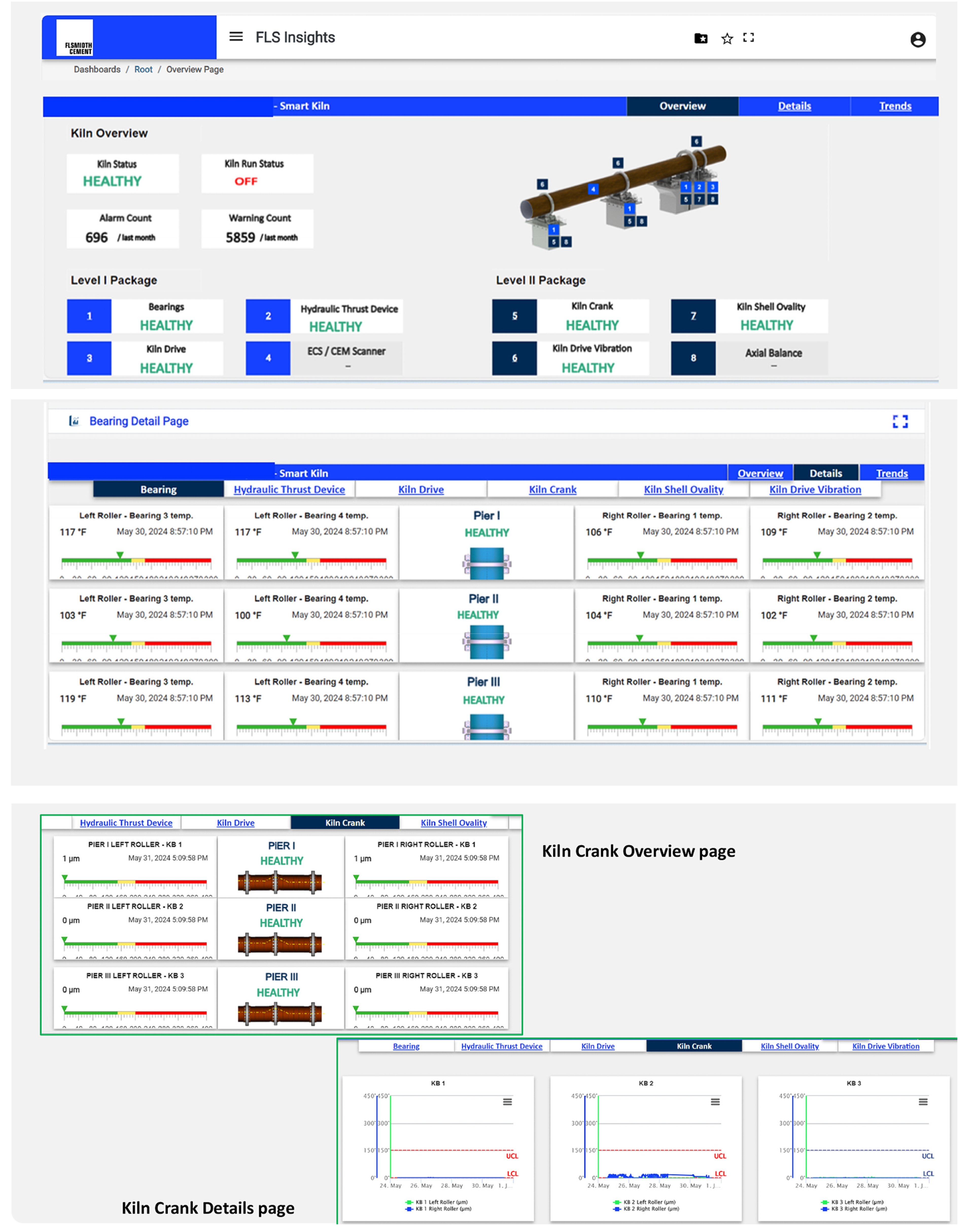

OCMS dashboards

In addition to the SiteConnect mobile app where you can view equipment performance data from anywhere in the world, as part of the OCMS package you also receive Customer OCMS dashboards at your plant. The dashboards – pictured here – can be seen on a PC monitor located onsite, in the Plant Head, Unit Head, Mech. HOD, E&I HOD or CCR room according to what suits you best.

The dashboards enable you to visualise:

- The overall picture of equipment health

- An overview of several equipment lines (Kilns, VRMs, etc.) in one place

- An indication of individual KPIs according to your OCMS equipment packages (eg. Level-I/Level-II)

- Detailed analysis of individual KPIs related to failure modes included in the OCMS package (e.g. Kiln crank, Kiln axial balance, etc)

- Further trends & analysis for individual components of the KPIs being monitored. (eg. Kiln Bearing temperature, HTD Pressure tc.)