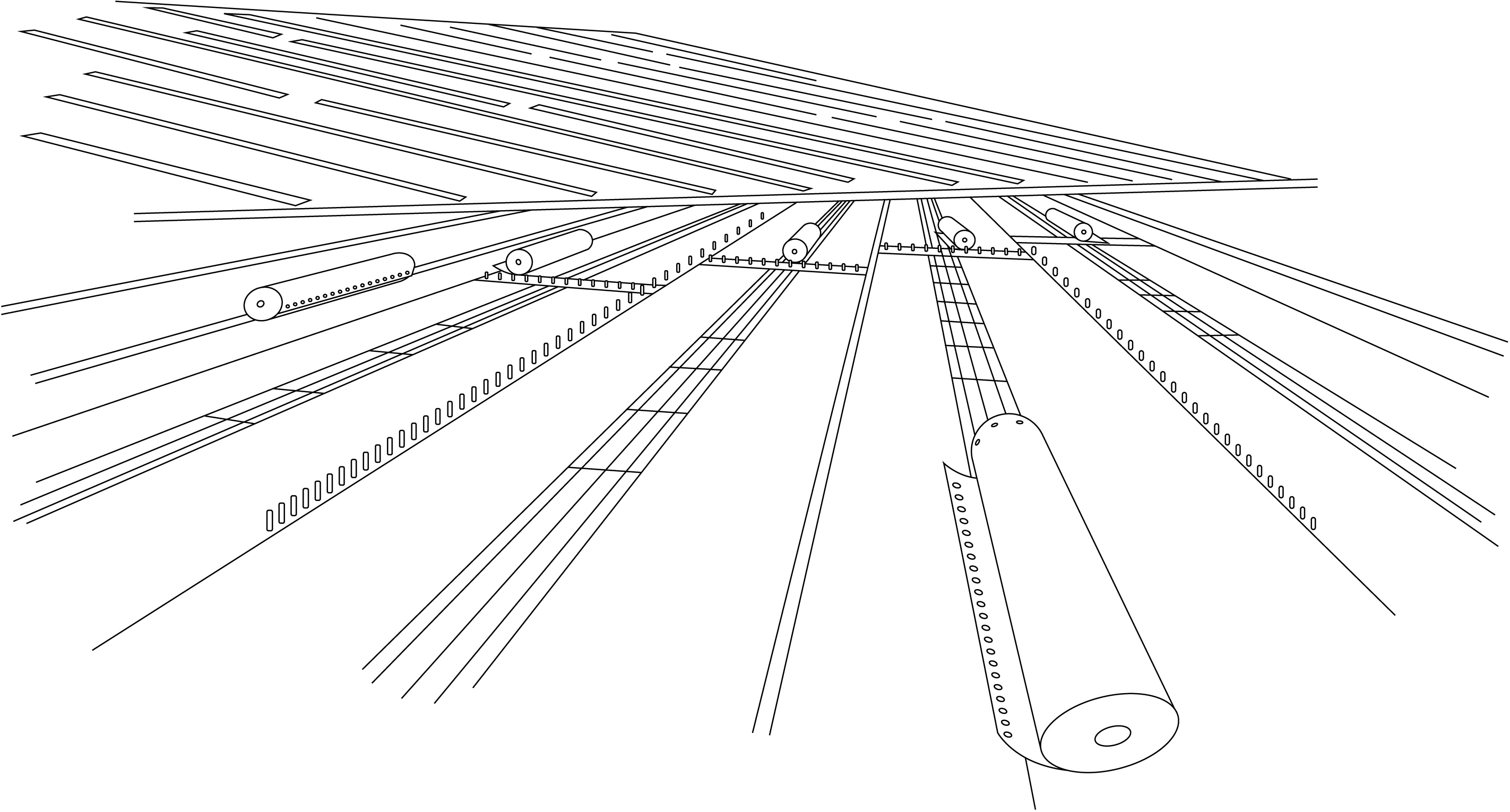

Complete material recovery with a aerator pneumatic reclaim system

_Pneumatic_Reclaim_System.png?w=1080&q=80&auto=format)

What we offer

Advanced silo fluidization for optimal withdrawal of materials

Dry bulk materials can be tricky. They have a tendency to bridge and cake, making it difficult to discharge them from the silo when the time comes. Materials that are left in storage can build up over time, causing yet more issues – and all the product you can’t reclaim is money and time wasted on retrieval operations that can be risky to personnel and silo structures. We use advanced fluidization technology to move material out of storage smoothly and effortlessly. Our Ful-Floor™ reclaim systems use industry-proven FLSmidth Airslide® fabric anchored to nearly 100% of the floor area. Pushing air through the Airslide® fabric enables material to move swiftly and easily. Embedded aerator troughs and piping eliminate restrictions that can inhibit material flow. The gentle slope directs the flow of material out of storage, ensuring nothing is left behind. That’s it – air, gravity, and very little power consumption. Simple, but effective. And because there are no moving parts inside the storage area, the system requires little maintenance, giving you maximum availability at low operating costs.

More product, less power – efficient aerator storage reclaim solutions

Using advanced Airslide aerator technology enables you to move more material, faster. With reclaim rates upwards of 800 t/h, you can guarantee it won’t be your storage reclaim system slowing you down. And with efficiencies greater than 99% you’ll also be happy to spend less time retrieving product from storage. In fact, there is rarely a reason to enter a partially-filled storage dome when you’re using Ful-Floor aeration. It’s a flexible system that allows simultaneous filling and reclaim. It’s also possible to select reclaim areas for complete drawdown, giving you a means of stock rotation that’s not possible with mechanical systems. You can opt to have the discharge point at the side or centre, according to your installation requirements.

Maintenance and dependability

There are no moving parts inside the storage area, and with minimal abrasion on the floor surface, fabric wear life can exceed 20 years. Routine maintenance on the blowers and air control valves is the only requirement for automatic, trouble-free material reclaim.

Silo fluidization configurations that suit your application

Every installation is designed with you in mind. Your materials, your capacity requirement, your application. Cone bottom storage silos are the most common for silo diameters under 14 meters (46 feet). Simple fluidization is usually provided on the cone walls to aid in continuous flow of material during the discharge operation. Open Airslide sections spaced equally around the cone can be activated all at once, individually, or in groups. Storage silos with 50 – 70˚ cone bottoms require minimal fluidization to prevent rat-holing and material bridging.

Total terminal system management

Our technology and commitment to product development and testing have made FLSmidth the leading supplier of storage silo fluidization and withdrawal. But reclaim from storage is just one part of terminal system management. FLSmidth can design and supply your complete control system to distribute the material flow, monitor inventory and transfer between storage facilities or directly to trucks, railcars, barges or ships. And throughout all these projects our focus remains on finding you the best solutions to improve productivity and profitability, safely, cleanly and effectively.

downloads

Article: Continental Cement – bigger and better storage

04.04.2024 |

121.24 KB |

English

Dome Technology article: Titan-Chesapeake Project summary

10.06.2024 |

514.86 KB |

English