Long-lasting wear solution tailored to the demands of our OK™ mills

ProCeramic_Wear_Segments.png?w=1080&q=80&auto=format)

What we offer

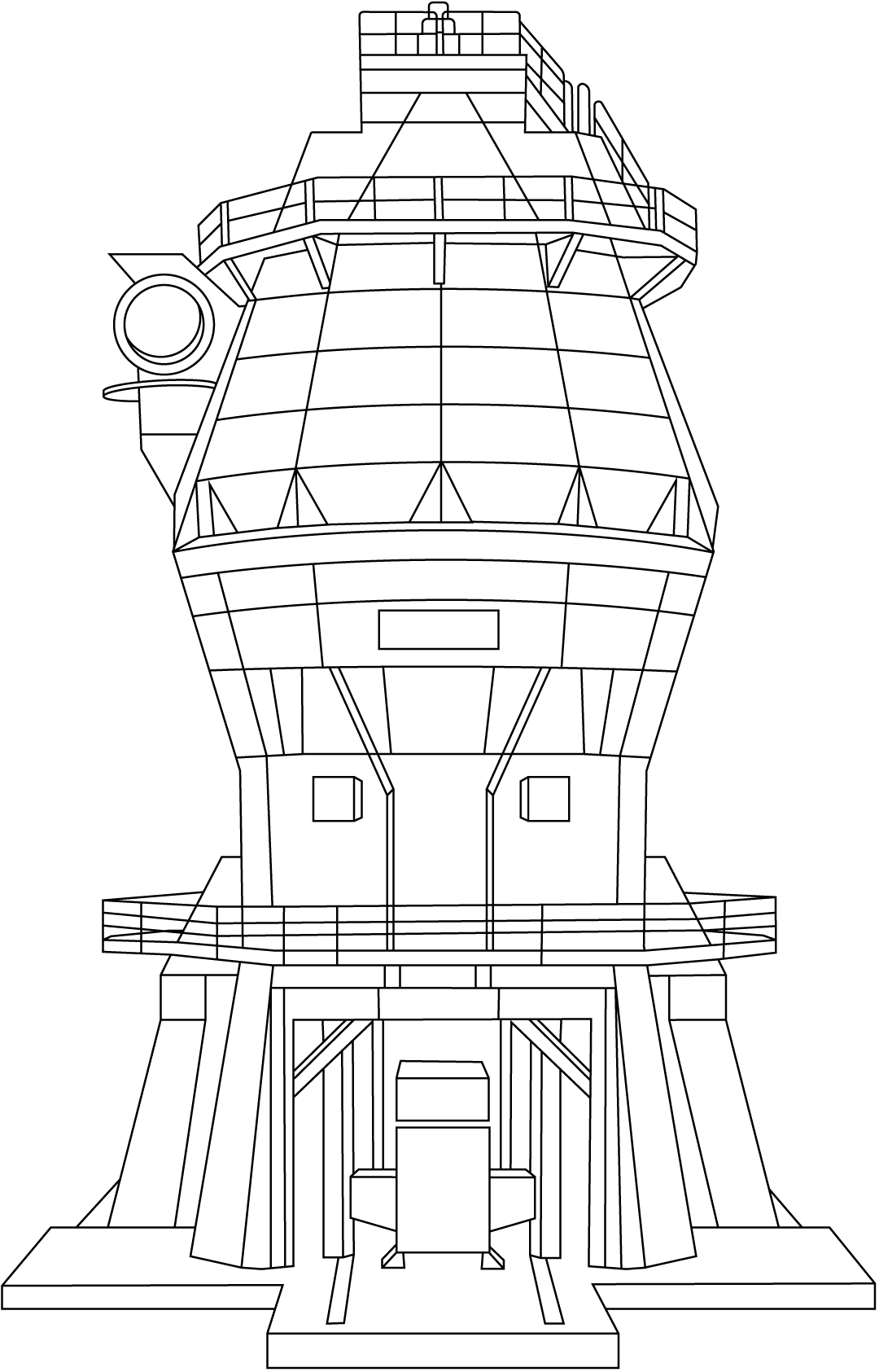

A best-in-class mill deserves a tailored wear solution

The common maintenance practice for worn VRM roller and table wear liners is to reweld or hard face the worn surface. This means regular stops to mill operation. But because the wear rate in a VRM varies, depending on feed materials and product fineness, the number of times maintenance is required over a given time period is variable. With up to 3 times the wear life of traditional high-chrome liners, OK™ Pro+ ceramic wear segments reduce the number of maintenance stops, offering a long-lasting wear solution for our OK™ raw, cement and slag mills. And because they are designed by us for our mills, they’re guaranteed to ensure mill performance stays at the high level you expect it. They also bring sustainability advantages compared to third-party wear liners, which may not fit as well or be made from inferior materials. By ensuring mill performance remains at optimum levels, grinding efficiency is maintained and energy consumption is optimised. There is also less consumption of wear parts (because the OK™ Pro+ liners last longer) and they can be recyclable at end-of-life, minimising waste.

A wear solution that helps get the most out of your mill

Improve mill productivity with fewer maintenance stops

When your mill is down, you aren’t producing. And when you’re not producing, you’re not making money. It’s a simple equation. Traditional wear control strategies for VRMs require regular stops to the mill in order to reweld or hard face the wear surface. While we may be experts in vertical mill technology, we can’t actually stop wear in your OK™ mill. But what we can do is make sure that the interval between wear lining maintenance stops is as long as possible – up to two and half times longer than alternative wear solutions, in fact. This means your mill is up and running for longer. Which is what everyone wants a mill to be.

Guarantee mill performance with an expert OEM-made solution

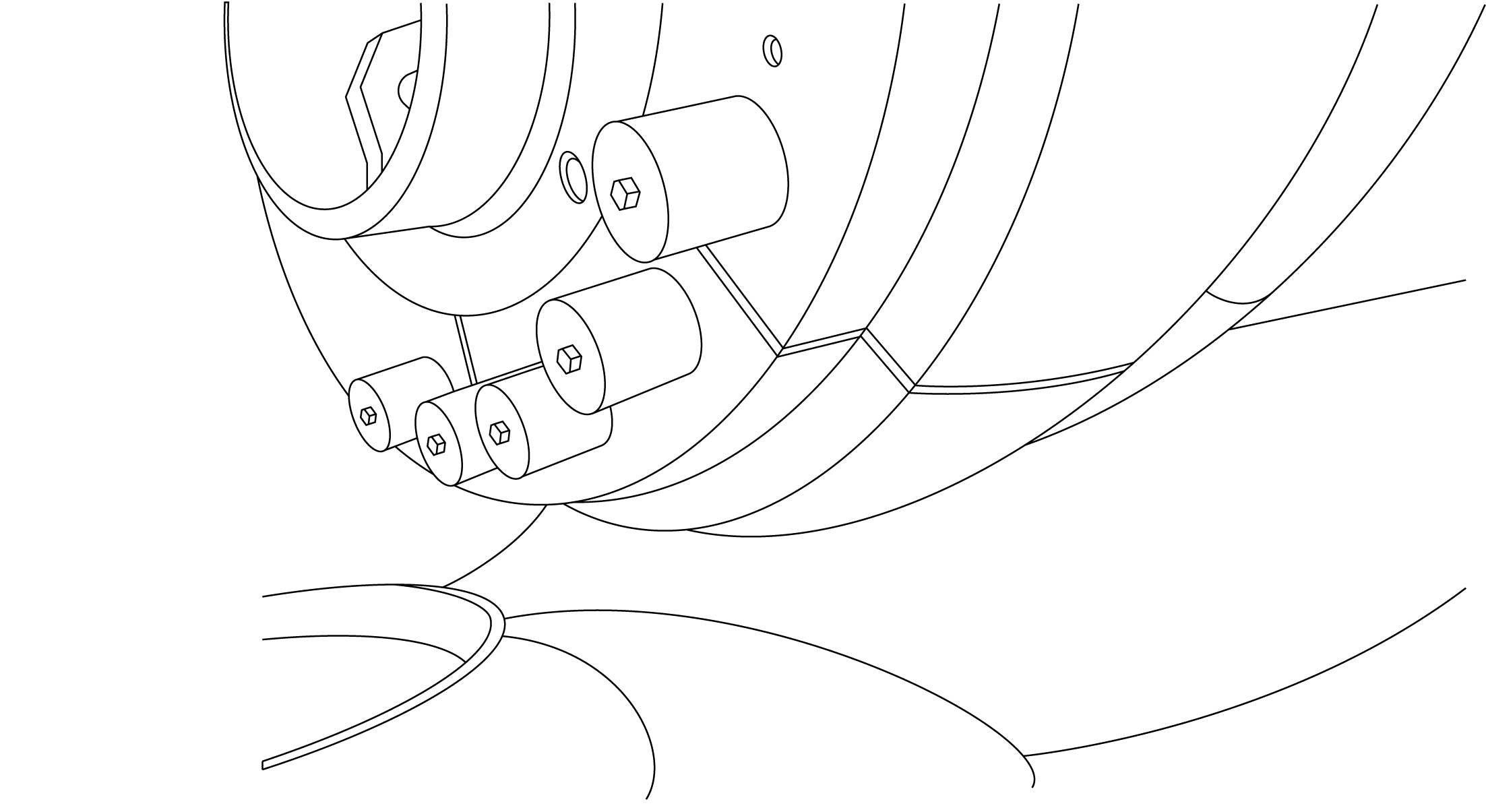

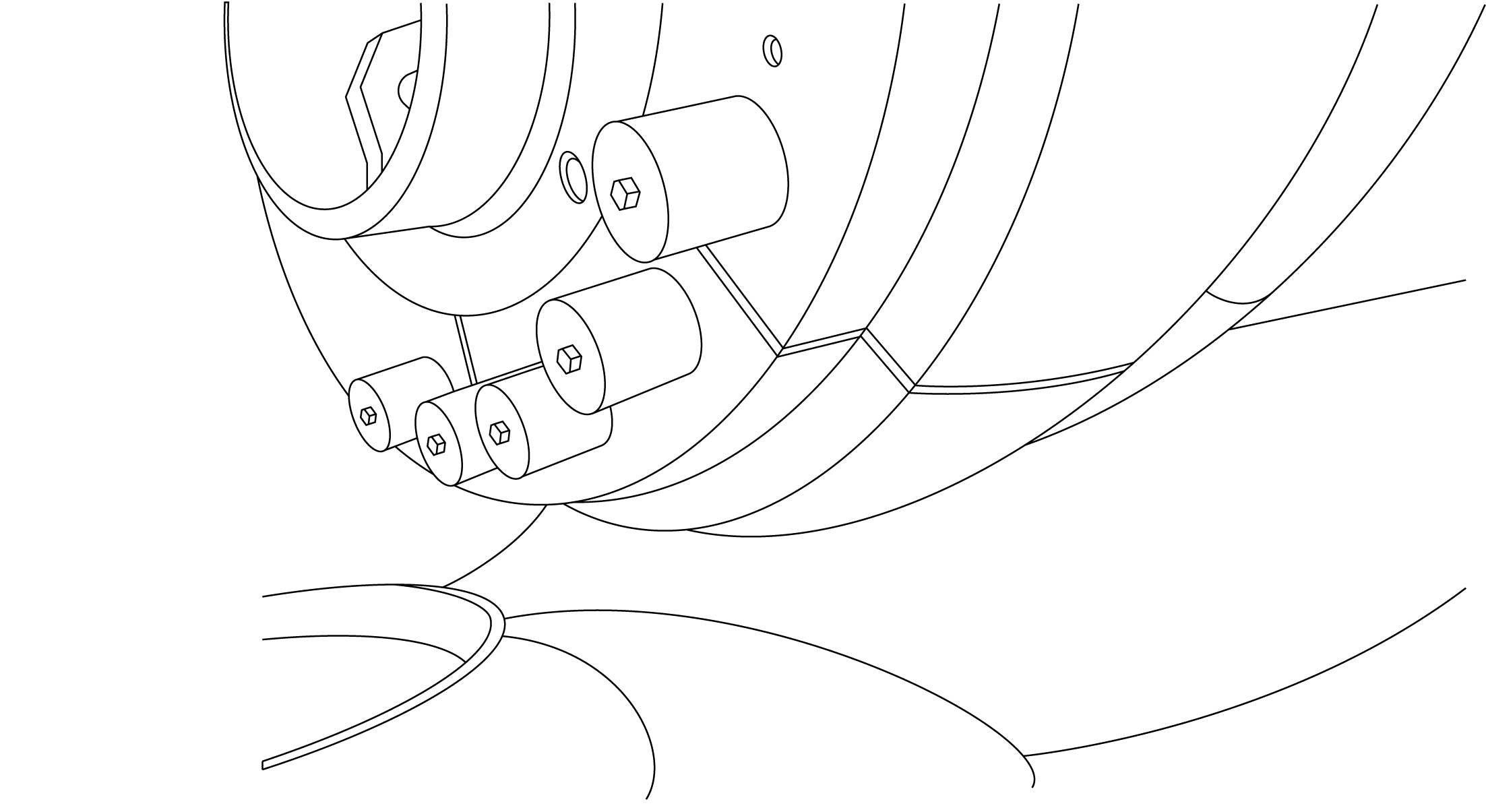

We also make sure that our OK™ Pro+ ceramic wear segments fit. Sounds simple. Not so in practice. The grinding parts inside of an OK™ mill are made to exacting specifications. Making sure the wear liners are made and installed correctly is not an easy task. But it is an important one. Ill-fitting wear segments may upset production rates and stability, dragging down the production from your mill. With our first-hand knowledge, we are able to expertly manufacture our ceramic wear segments to fit the original tolerances of critical components with proper positioning and secure placement. The shape of the alumina (AL2O3) ceramic inserts has also been carefully selected to match the spherical dual-lobed surface profile of the OK cement mill, and properly placed to prevent localized wear areas that shorten the effective life of the liner segments. Before Pro+ ceramic wear segments are shipped we verify they meet our design specifications and standards. Which means your FLSmidth OK™ mill will continue to perform as you’d expect your FLSmidth OK™ mill to perform.

Reduce wear liner consumption with highest-quality materials

The ceramic inserts in OK™ Pro+ wear segments are 10mm thicker than those in non-FLSmidth liners, ensuring the wear resistant surface layer will last for the full production cycle. Meanwhile, the ceramic element is impregnated with a special hi-chrome alloy, ensuring better flowability during casting, and resulting in a dense material matrix with high hardness. When combined with the high-quality hi-chrome base material, this presents a durable and reliable technology for raw and cement/slag grinding that reduces both the need for wear liner maintenance and the overall consumption of wear materials.

Low-waste option as recyclable at end of life

We know performance is important. We also know that sustainability is a key factor. Reducing the consumption of wear materials is a good start. We’ve got that covered (see the section above). So is ensuring the mill remains as efficient and productive as possible to help optimise energy consumption. However, we also need to reduce the amount of waste produced during operations to help achieve circular economy and zero-waste goals - we’ve got this covered too. Our OK™ Pro+ wear liners are recyclable at end of life – so they won’t be cluttering up scrapyards at the plant or filling up landfills when their job in your mill is done.

_Raw_and_Cement_Mill.png?w=3840&q=80&auto=format)

ProCeramic_Wear_Segments.png?w=3840&q=80&auto=format)