Online condition monitoring services that reduce cooler downtime

What we offer

Expert data analysis – your no. 1 shield against unplanned downtime

Sometimes it can seem like equipment failure comes out of nowhere, but there are almost always early warning signs – often invisible to the naked eye. Unless you’re continuously capturing and analysing the data, you wouldn’t see it. And then outages take you by surprise, causing damage, high costs and untold stress. Our online condition monitoring services for Cross-Bar coolers log data from various parts of the cooler and send it via a secure connection to our Global Remote Service Centre. They’ll report back to you immediately on any areas of concern and provide regular reports and guidance on how to optimise your cooler health.

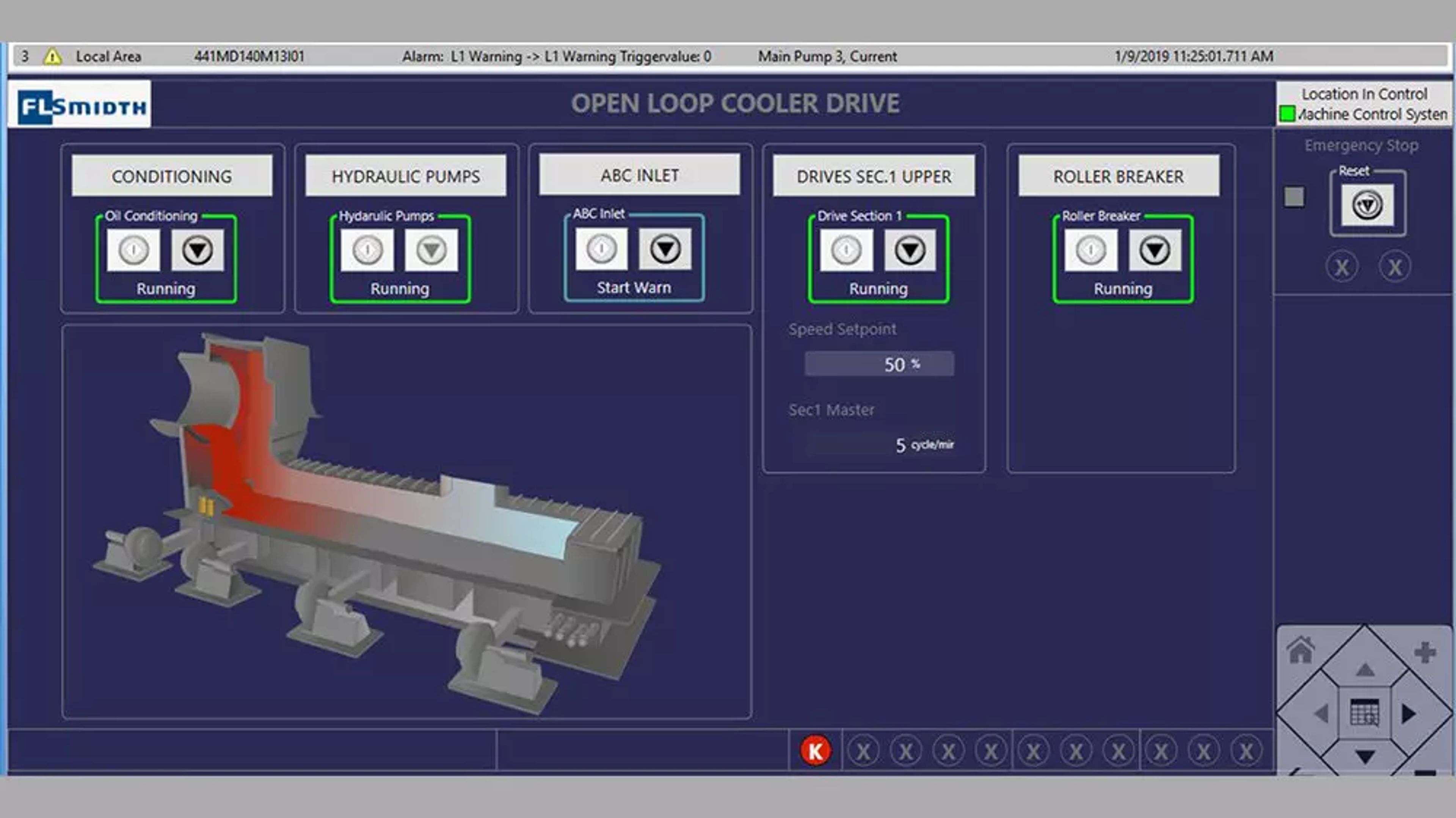

How does it work?

The online condition monitoring service for Cross-Bar coolers is an annual subscription service. It comes with a data logger and PC, which is connected to the team at FLSmidth’s Global Remote Service Centre. Key data is collected 24/7 and run through our specially developed algorithm, which flags up any irregularities for review by our experts. They will analyse the data. If there are any immediate concerns, they will report back to you straight away. Otherwise, they’ll collect the data into a regular report and use it to advise you on upcoming maintenance needs and ways to optimise cooler operations.

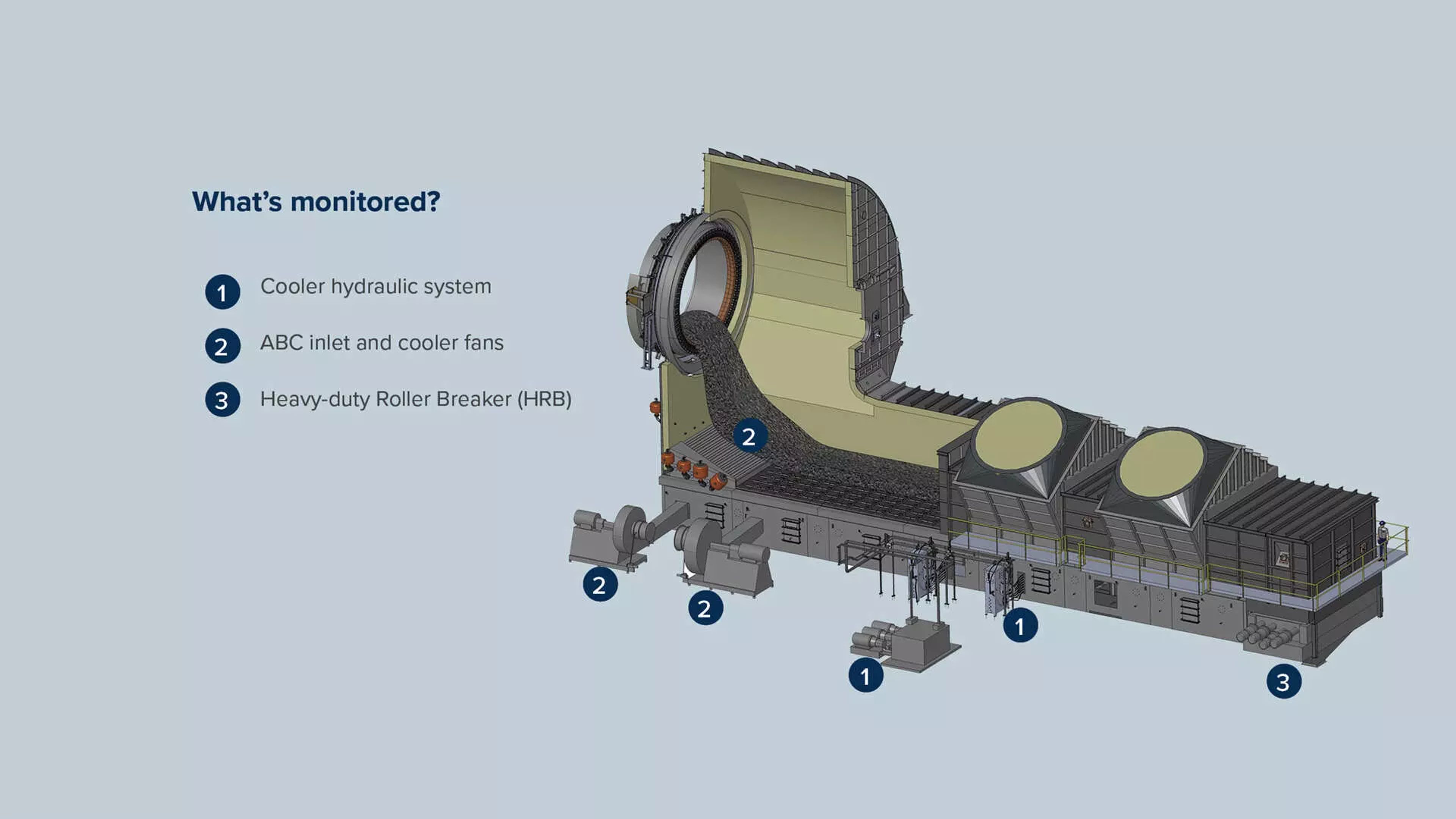

What is monitored?

With this package, we monitor the condition of your: Cooler hydraulic system, to evaluate the health and abnormalities of hydraulic pumps, cylinder seals and critical components by analysing Hydraulic drive force Hydraulic pump utilisation factor ABC inlet and Cooler fans, to ensure the long lifetime of wear parts and cooler health by analysing Recuperation zone cooling air coefficient and pressure drop coefficient Heavy-duty Roller Breaker (HRB), to monitor abnormalities and HRB health by analysing Roller torque, reversing frequency and bearing temperature

Predictive maintenance benefits

Online condition monitoring is a simple solution with far-reaching results. By connecting our experts to your equipment, we can keep an eye on the health of your Cross-Bar Cooler and give you the advanced notice you need to take a proactive maintenance approach. Reduce downtime Reduce the cost of downtime Improve cooler operations Reduce the safety risks associated with unplanned outages