Low-maintenance, low-energy gravity conveying for dry bulk materials

What we offer

Airslide gravity conveyor: a fluidized conveying system that just makes sense

With minimal fluidizing air and a gentle incline, Airslide Conveyors transport dry and fine-grained mineral bulk materials economically and efficiently. Working at speeds of 2000 m3/h and more, these enclosed fluidized conveying systems are dust-free, low wear and low maintenance, yet highly efficient. They can be used across the plant, in applications such as conveying bulk material from silos to vehicle or ship loading facilities, receiving material from bucket elevators for further distribution to silo chambers, or where multiple material flows meet for transport on to a common station. Thanks to the low conveying speed and simple construction, Airslide gravity systems convey even high volumes of materials gently, without segregation and with very low wear. This gives you a long equipment life with virtually no maintenance. Our Airslide Conveyors are built with flexibility in mind, so we’ve designed a variety of attachments and accessories to enable a broad range of uses. Branch points, distributing systems, ejection flaps, or shut-off units and regulating units enable a large number of individual conveying section variations. Adaptations can also be made for high-wear or high-temperature materials up to 400°C.

Economical, low-maintenance pneumatic conveying with zero dust

Dust-free conveying

When you’re handling fine-grained materials like cement and fly ash, dust and spillage are a real concern. It’s bad for your equipment, and for the environment – not to mention your relationship with the local community. Airslide gravity conveyors are totally enclosed pneumatic conveying systems that give 100% dust-free conveying – no mess, no fuss. It’s also very quiet, since the only part to make noise is the system’s air supply, which is generally located in a remotely insulated area.

High throughput, low cost

Dense-phase conveying allows high material transport volumes with low conveying air use. It’s a gentle way of conveying large volumes of fine and powdery dry bulk without risking material segregation or grain attrition, ensuring optimum product quality even at throughputs over 2000 m3/h. The gentle incline of the Airslide – adjusted for each material and application – contributes to the easy flow of material, giving you incredibly low energy costs and easy operation.

Flexibility

The flexibility of Airslide Conveyors enables bulk material temperatures up to 220˚C as standard, and up to 400˚C with specially adapted fluidising fabric. Investment costs are low and you can build the system that best suits you with our extensive range of accessory options.

Low maintenance

Maintenance is often where your conveying system lets you down. It’s a messy business and there are a lot of moving parts. But that’s not the case with a pneumatic conveying system like the Airslide gravity conveyor. Maintenance of the Airslide Conveyor is very simple because there are no moving parts other than the air supply equipment. Airslide Conveyors require no lubrication. With zero dust and very low maintenance, you get a highly reliable material transport solution that’s kind to the environment and to your operating budget.

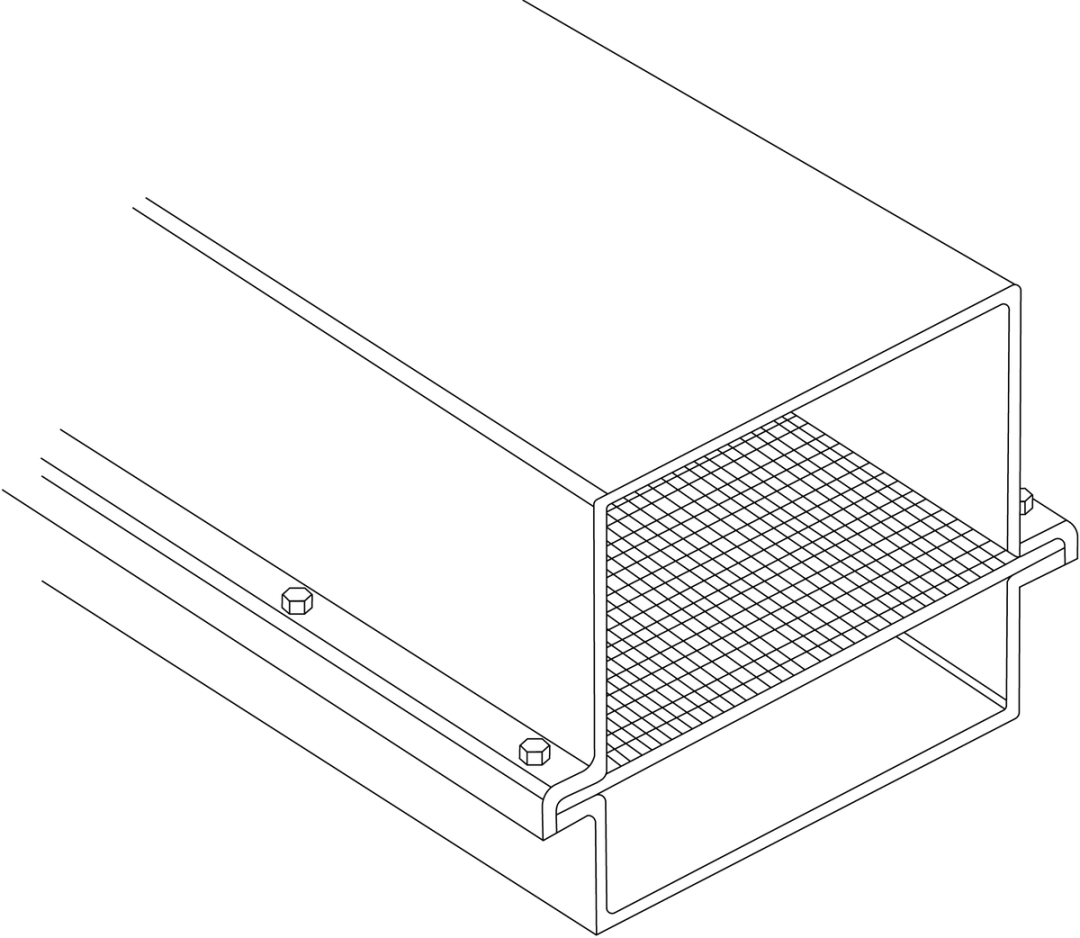

Working with nature to deliver eco-friendly air slide pneumatic conveying

So how does the Airslide harness the natural force of gravity to provide gentle but high-volume pneumatic conveying? The pneumatic Airslide gravity conveyor consists of an upper trough and a lower trough, with a porous fabric clamped between the two. Material to be conveyed is fed into the upper trough, while the lower trough is charged with a low-pressure fluidizing gas – usually air. This passes through the fabric and fluidizes the material, but the material can’t pass through the fabric. Material flow is achieved by sloping the Airslide Conveyor to match the fluidized angle of repose to the powdered material. At the correct angle, fluidized materials flow with the consistency of a liquid. Every installation is tailored to your material and application. The whole process requires very little energy – just 0.02 kWh/t per 100 m of conveying length. Our Airslide Conveyors have a robust and simple structure. As they are installed overhead, valuable floor space and added headroom are available for other purposes. By eliminating the need for massive support members, it permits a flexibility of plant design not available with straight-line conveyors. Low investment costs and energy-efficient operation result in an optimal pneumatic conveying system that is quiet and clean.

Typical Airslide Conveyor Applications include:

- Distribution from bucket elevators to storage silos

- Gathering under baghouses / precipitators

- Feed to process

- Feed to other conveyors

- Loadout from bulk silos to trucks, railcars or barges

- In-plant conveying

- Storage silo / bin withdrawal