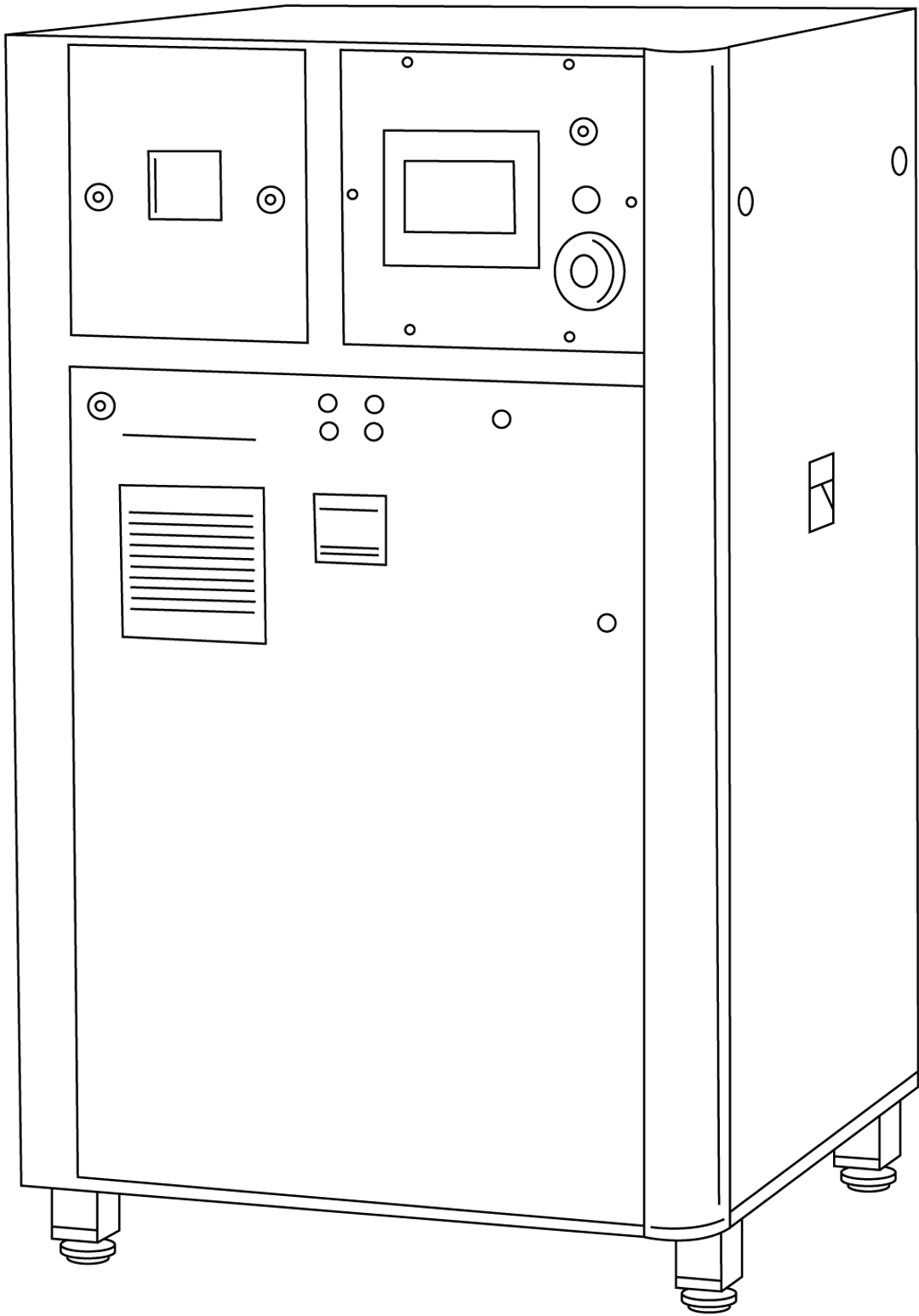

An all-in-one automated solution that streamlines grinding and pressing

What we offer

Fully automatic, large capacity unit for stand-alone or automated production

Laboratories tend to be tight on space, high on demand. The pressure is on to deliver accurate results, fast. Standing with a footprint of just 1 m², the QCX® Centaurus Combined Mill and Press offers an all-in-one automated solution that can grind and press. It also offers optional ‘grinding only’ or ‘pressing only’ features. This is a unique characteristic that you will not find anywhere else. This adaptable machine produces pressed powder test tablets from granular materials, such as raw meal, clinker, cement, ore, slag and exploration samples for x-ray fluorescence (XRF) and x-ray diffraction (XRD) analysis. Grinding and pressing is automated – saving your staff from many of the labour-intensive and tedious tasks associated with preparing pressed pellets. And you get high quality, accurate analysis time after time. Centaurus is a modular system that will grow with your needs. Either use it as a standalone system or integrate it into a fully automated laboratory with minimal additions.

Flexible and functional future-proof design

How much more efficient could your process be with automated sample preparation?

Flexible

This unit has the ability to create and store up to 99 sample preparation programmes, making it quick and easy for the operator to set up for different sample types.

Consistent

Grinding is a heat-intensive process and that can impact your sample. The Centaurus provides the option of both air and water cooling to ensure the appropriate temperature is maintained for optimum sample quality.

Improved capacity

More laboratory capacity is available because of fully automatic preparation cycles (optional input/output magazine). Operators are free to undertake more meaningful and important tasks, making it an intelligent cost-effective solution

Future-proof

The modular compact design enables a customer-tailored solution. Future upgrades are simple, however your needs change.

Easy to maintain

With lab space at a premium, you need to be able to position the Centaurus in a way that suits you. That’s why we’ve designed it for easy maintenance access. Only two sides need to be available for maintenance, so you can choose how to position it in your laboratory layout.

Versatility and performance – a mill and press that you can rely on

The fully-automatic QCX Centaurus Combined Mill and Press grinds and presses samples for a range of applications. It has been designed to function as a stand-alone system but works equally well as an integrated component in linear and robotic automation systems.

The process works as follows:

1. The mill is flushed with some of the sample material

2. A sample quantity is volumetrically dosed by a two-volume sample dosing spoon

3. Grinding aid pellets are dispensed

4. The sample is pulverised and transferred to a steel ring

5. The sample is pressed by a pneumo-hydraulic press unit

6. The cleaning process is fully automated using compressed air together with dedusting

7. Excessive dust is removed from the tablet surface

8.A vacuum integrity check is performed

9.The pressed pellet is delivered to the operator or automation side of the machine

10. Post analysis, the steel ring is returned for automatic cleaning.

The Centaurus is well-known for its quality, capacity, ease of use and reliability in sample preparation. The ‘grinding only’ and ‘pressing only’ functions are optional, making it truly adaptable to your requirements. It’s simple-to-use touchscreen control panel makes it easy for the user to set up and operate. The internal parts of the machine are self-cleaning, improving safety and reducing the need for the operator to handle heavy grinding tools.

Sample preparation is the most common source of error in quantitative X-ray analysis. With this machine, the opportunity for errors is greatly reduced. High-quality samples are delivered every time, giving lab staff more time to focus on productivity. Consistency is at the heart of accuracy – and that’s why automated machines are so successful at these types of tasks. The Centaurus maintains consistency in the repetitive tasks of grinding, sample weighing, dosing, pressing and cleaning. The instrument can prepare up to 10 samples per hour from coarse material to finished pressed pellet ready for analysis. And operators are free to spend their time on more demanding and important tasks, resulting in cost savings.

With the lowest possible cross contamination and the highest reproducibility, the Centaurus is a smart, adaptable machine that will significantly improve productivity in your laboratory.