Are you looking after your kiln shell monitoring system?

What we offer

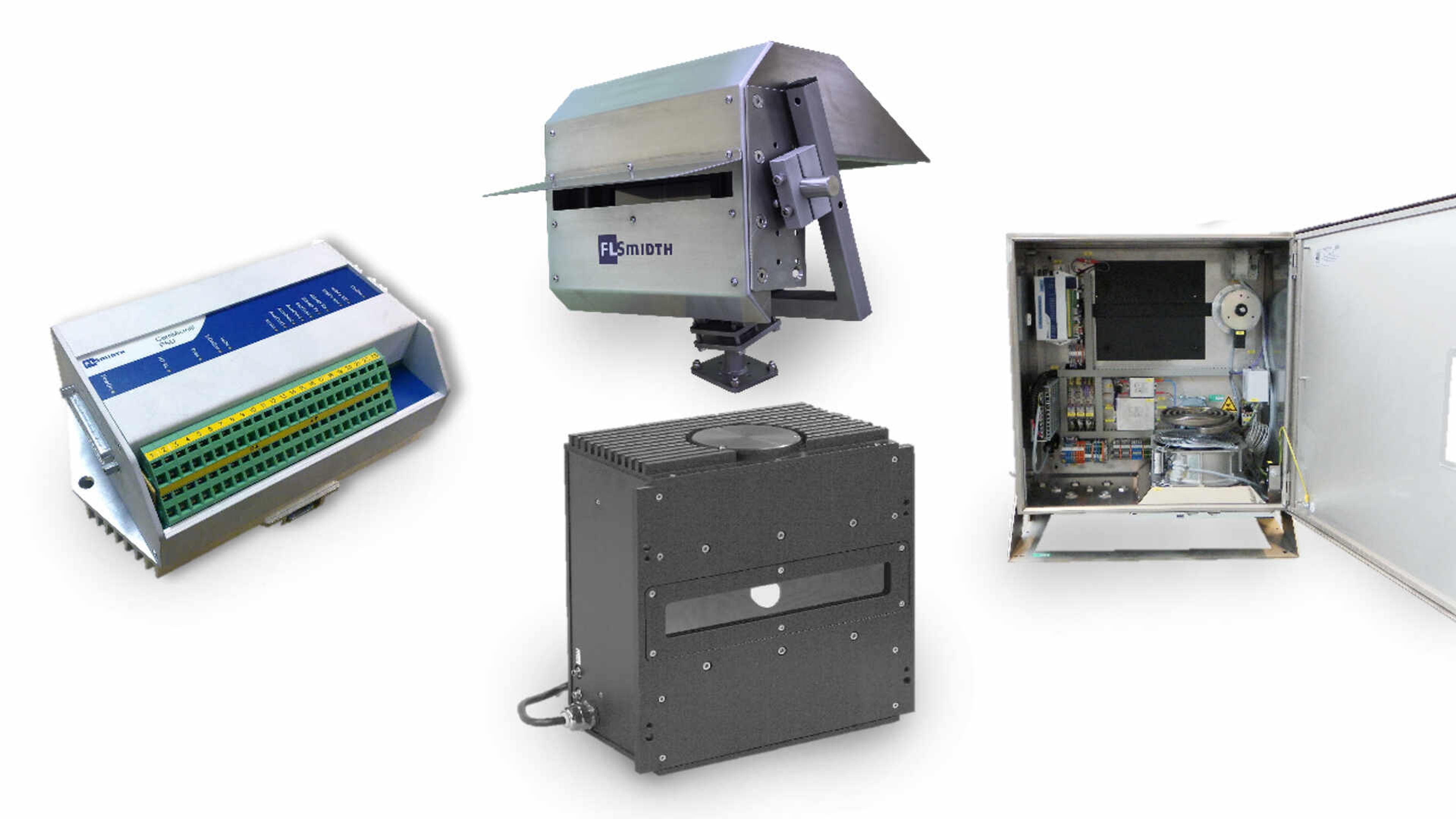

Maintaining high accuracy – CemScanner

When was the last time you checked on your CemScanner? This crucial instrument is notoriously reliable – but it’s not indestructible. A build-up of dirt could blind the scanner head. A knock could push it out of alignment. Would you know if the temperature measurements were a few degrees out? All instruments require recalibration and a good cleaning to make sure they can perform as they were intended. The CemScanner is no different, which is why we’ve put together a simple maintenance package to take care of your CemScanner. As part of your annual maintenance routing, schedule a visit from FLSmidth to perform a thorough ‘once-over’ to ensure that the measurements you’re getting reflect the reality in your process.

Our CemScanner preventive maintenance services include:

• Calibrate scanner head

• Check and correct scanner alignment

• Replace filters, clean window, and cabinet

• Check electrical and network connections

• Review available software service packs and hot fixes and install as necessary

• Complete review of the operating condition of the complete system (servers, clients, network) to find current or potential problems

• Windows event and performance logs

• Network monitoring

• Security vulnerability analysis

• Review with engineers and operators the current functionality for bugs, and areas that need improvement

• Improve and enhance the system as necessary to ensure the system is meeting the user needs

• Review alarm and event logs and take corrective action as necessary

• Check system configuration

• Customer training

• Additional services are also available, such as implementing automated kiln shell cooling fan control, and enabling your CemScanner to communicate with your data historian and analytics systems.