Reach a new level of cement production quality control

What we offer

Increased production stability and higher profitability

Do you want superior, steadier raw meal quality, cost-efficient additive control and reduced fuel consumption? Advanced quality control systems minimise variability in raw material proportioning – but not all do it equally well.

Top-quality chemical control you can trust

Our latest generation of QCX/BlendExpert advanced software helps cement plants to rise above the many challenges of consistently producing high quality products at a lower cost. With QCX/BlendExpert, the complex task of controlling varying raw materials is no longer manual. We have taken cement production to a new level. Increasing productivity. Becoming more sustainable. And enhancing product quality.

And with over 700 QCX/BlendExpert applications in operation around the world you know it delivers high quality results – all day, every day.

State-of-the-art technology

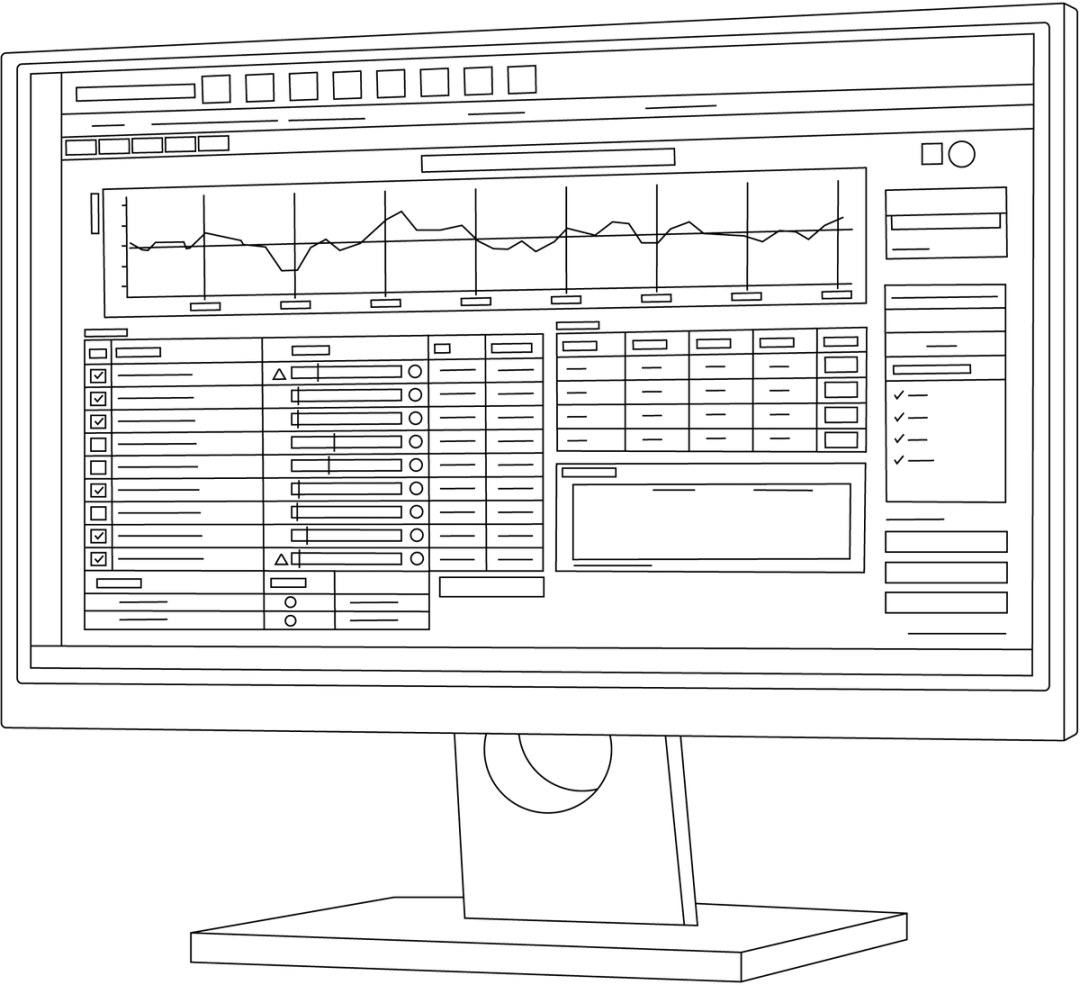

QCX/BlendExpert™ is an advanced suite of software applications that performs the complex task of controlling the raw material feed to stockpiles, raw mills and cement mills, or other blending systems. By performing sophisticated analyses of the chemical conditions and automatically adjusting the set-point of material and additive feeders, QCX/BlendExpert gives you superior quality control and greater efficiency. And greater control adds to your sustainability.

The package has a range of applications, with optional add-ons to complement the system’s capabilities:

- QCX/BlendExpert – Mill

- QCX/BlendExpert – Pile

- QCX/OnlineExpert

Now in its eighth version, QCX/BlendExpert uses the latest control technologies, such as model-based predictive control. Together with today’s powerful PC processors, the software is capable of very complex process simulations and estimations.

Superior chemical control giving your cement plant a competitive edge

To remain competitive in today’s cement industry, it’s essential to tap into the latest technologies. With QCX/BlendExpert, you get the benefit of more than 50 years of innovation, and our vast experience in automating cement production processes. QCX/BlendExpert meets these challenges head on.

The software optimises raw material blending to improve the quality of your product, and ensures you meet peak quality targets. By minimising the variability in raw material proportioning, the new generation QCX/BlendExpert software lowers lime saturation factor (LSF) standard deviation by up to 60%.

The cost benefits of this unique system give you fast payback on your investment. With less variability in your raw product, there is less thermal stress on your kiln and preheater. This translates as cost savings in lower fuel consumption, and less wear on mechanical parts – meaning a longer lifetime.

Capex budgets are often limited, and the QCX/BlendExpert system can help there too. With better control over your raw materials, there is a reduced need for costly blending silos, for new plant builds. And in existing plants, the system compensates for poorly functioning silos. Plus, you will find production becomes more cost-efficient. The system ensures you get the best use of your raw materials and additives. Along with reduced fuel consumption, this can add up to real cost savings.

Sustainability is at the heart of everything we do. And we know it is an important part of your business too. With QCX/BlendExpert, you can achieve higher kiln alternative fuel substitution rates without jeopardising the quality of your clinker. And stable kiln operation gives you stricter control over emissions.

We understand you need to operate 24/7/365. So, QCX/BlendExpert helps you achieve that. The system directly monitors feeder operation for fast trouble-shooting, and it has unique capabilities that maintain optimal chemical control during upset conditions. Plus, with stable kiln operation, there is less stress on kiln parts, such as the lining, which means fewer and shorter kiln stops. The end result? Steady production, with less downtime.

Our passion for improving your productivity led us to create a solution that completely automates the complex task of controlling raw materials. The dynamic bias correction gives highly accurate estimates of chemical values, so it eliminates the need for specific sampling and analysis of raw materials into the feeders.

All our screens are intuitive so users get an easy overview and ‘next step’ operation. And as an added option, our 24/7 PlantLine Service Agreements can provide you with expert online monitoring and support, maintenance services, troubleshooting and a range of other services. This means you can leave the quality control up to us, and get on with other important tasks.

A high-tech quality control system designed specifically for cement production

From the quarry to delivered cement, the QCX/BlendExpert suite of applications optimises your operation.

Advanced blending technology

Its sophisticated algorithms take the accurate analysis from the laboratory XRF, and integrate this with the high frequency, but less precise online analysis results. Taking a range of other process parameters into consideration, the software then continuously corrects the bias of the online analyser to create highly accurate, real-time estimates of chemical composition. Based on these results, the system constantly adjusts the set-point of material and additive feeders to achieve the ideal blend. Driving productivity, and delivering substantial quality improvements.

Versatile

QCX/BlendExpert software works in tandem with our package of other QCX® quality control solutions, including QCX/AutoSampling and QCX/RoboLab. But it is still compatible with most other plant control and quality control systems, or it can be operated as standalone software. It can be installed on a standard PC, either physical or virtual. It is designed to work in tandem with QCX/Reporting giving you extensive reporting, trending and alarm handling capabilities.

Quality Manager, Cement Plant