Tailored CEMS solutions that keep you in compliance

.png?w=1080&q=80&auto=format)

What we offer

Process insights that help keep you in compliance

Your process is complex and the penalty for exceeding emissions allowances is severe. But the good news is, we can give you the insight you need to ensure exceedances do not happen.

What emissions measurements do you need to know?

Cement and other combustion industries are dealing with a multitude of gaseous and particulate emissions. Our technology is designed to be adapted to your needs, measuring components such as O₂, CO, CH₄, CO₂, NOx, SO₂, VOC, HCl, HF, NH₃, H₂O, Hg, as well as dust (PM), opacity, flow, temperature and pressure. This flexibility ensures you always have the information you need, when you need it. Our stack emission analysis systems can be built to meet the requirements of EU, TÜV, MCERTS, EPA and other standards. All our solutions are pre-approved during site testing of emission control equipment and emissions analysis to ensure we deliver what you need.

Bespoke emissions monitoring systems

We work with you to determine the optimum solution for your specific needs. After an initial site visit and a conversation, we can work out what and where you need gas analysis according to your regulatory requirements, production permits and plant layout. Most systems are installed in the stack using a combination of extractive and in-situ systems to give you the best overall picture of your process gases. When it comes to emissions reporting, the format is generally dictated by the relevant authorities. We make sure that you can deliver on their requirements and provide evidence of the operation and correct calibration of the analysers.

Reliable. Robust.

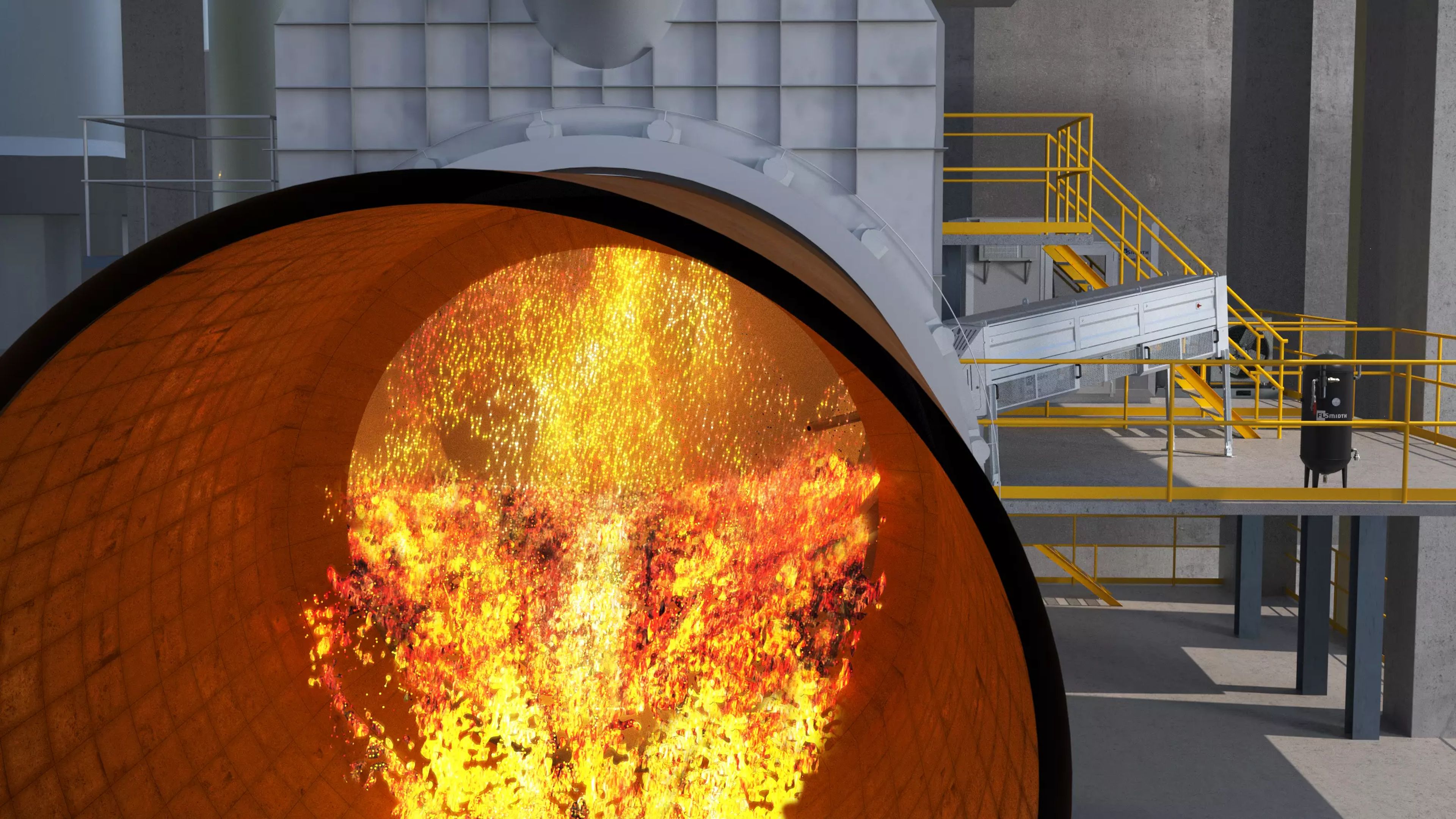

Emissions monitoring systems keep you in the loop with what’s going on in your process. When your monitoring system goes down, you’re effectively running the kiln blind. No combustion process can afford to be in the dark on what’s coming out of the stack. That’s why all our solutions are carefully designed and selected to be robust and reliable. Minimal maintenance. Minimal interference. Just optimum performance.

Complete CEMS solutions, designed around you

How can you reduce your environmental footprint and still be profitable?

This is the question that keeps heavy industry up at night. Everyone is under pressure: Bring down costs. Comply with emissions regulations. Increase productivity. Be more efficient. Win a greater market share. But the good news is, you’re not in this alone. We are committed to utilising existing technologies and finding new ways to make this happen.

Greater understanding of your process leads to better management

Emissions monitoring is a key first step in reducing your environmental footprint. Exhaust gases tell a story about what’s going in your process and the implications that has on the whole system. With the right data to hand, you can adjust your process to minimise emissions and increase efficiency. Small changes can have a big impact – both on the planet and on your bottom line. That’s how an emissions monitoring system can improve your performance.

Complete CEMS solution tailored to your legislative requirements

Globally, emissions regulations are complex and inconsistent. While one country might be concentrating on mercury, another will be cracking down on NOX or CO. There’s no one-size-fits-all compliance solution because the regulations themselves vary so widely. As a global supplier with an in-depth understanding of the market in which you operate, we’re able to navigate these variables and design an emissions monitoring system that works for your plant while meeting any national or international standards or legislation. As an independent supplier, we will configure the equipment according to the principle of Best Available Technique known as BAT. Sure, regulations have never been so stringent – but the technology is up to speed. We can make you more efficient. We can help you lower costs. We can give you the insight you need to ensure exceedances do not happen. We can assist you with service, support, spares and training globally. One supplier, one service partner. Let’s put an end to those sleepless nights and get to work on a solution

Plug and Play option available

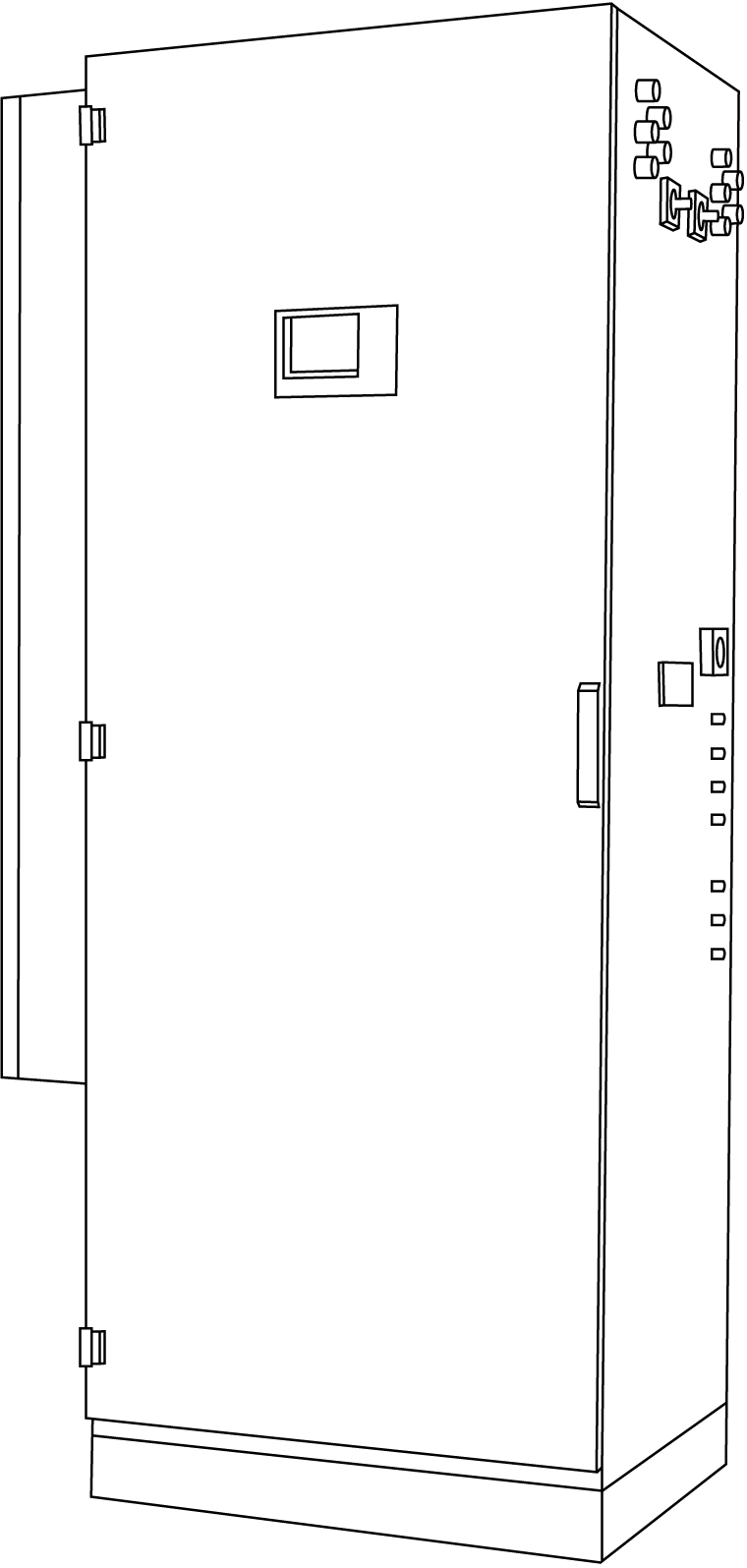

Organising all of your emissions sampling and analysis is a big job. We developed a complete Plug and Play solution in a pre-built on-site unit, the GASloq CUBE, which handles all the necessary analysis equipment through one common HMI interface. This setup takes care of the correct handling and operation of all the analytical equipment and can further be extended with our reporting package, ReportLoq. This dedicated emission reporting system collects all data in a normalised format and produces and stores emission reports according to your needs.

What does an FLSmidth CEMS solution include?

Our GASloq gas analysis system is equipped with the tools you need to sample, condition and analyse – and turn that information into data that will help you prove compliance and improve sustainability. Three different models of the GASloq gas analysis system are available: the 600, 800 and 1200. The capacity of these systems may be different, but the expertise is always the same. And so is the operating platform – so if you can use on GASloq, you can use them all. We also offer the GASloq CUBE, a complete Plug and Play solution ideal when there isn’t space to install the GASloq system indoors. GASloq CUBE is basically a complete analyser room with everything you need to get to work – including a desk and air conditioning!

Gas sampling

Our analyser systems are based on extractive gas sampling. Probes continually remove gas samples from the process or stack and draw them up through a sample hose to the gas conditioning unit.

Gas conditioning

The gas conditioning unit is individually designed for each application, depending on the gases, the contaminants, etc. It prepares the sample for analysis to ensure the most accurate read.

Control

All operation and supervision of the gas analysis system is performed from the GASloq cabinet through the HMI. The PLC controls the function of all connected instruments and components. External communication from the GASloq system can usually be matched to your plant control system.

Gas analysis

We don’t produce our own gas analysers, so we’re free to choose from the best available technology in accordance with the requirements of your application. We select the best instruments from a range of suppliers, including: