Reliable rotor weighfeeder for gravimetric dosing of pulverized coal

What we offer

Simplicity and precision: coal feeding that improves your process

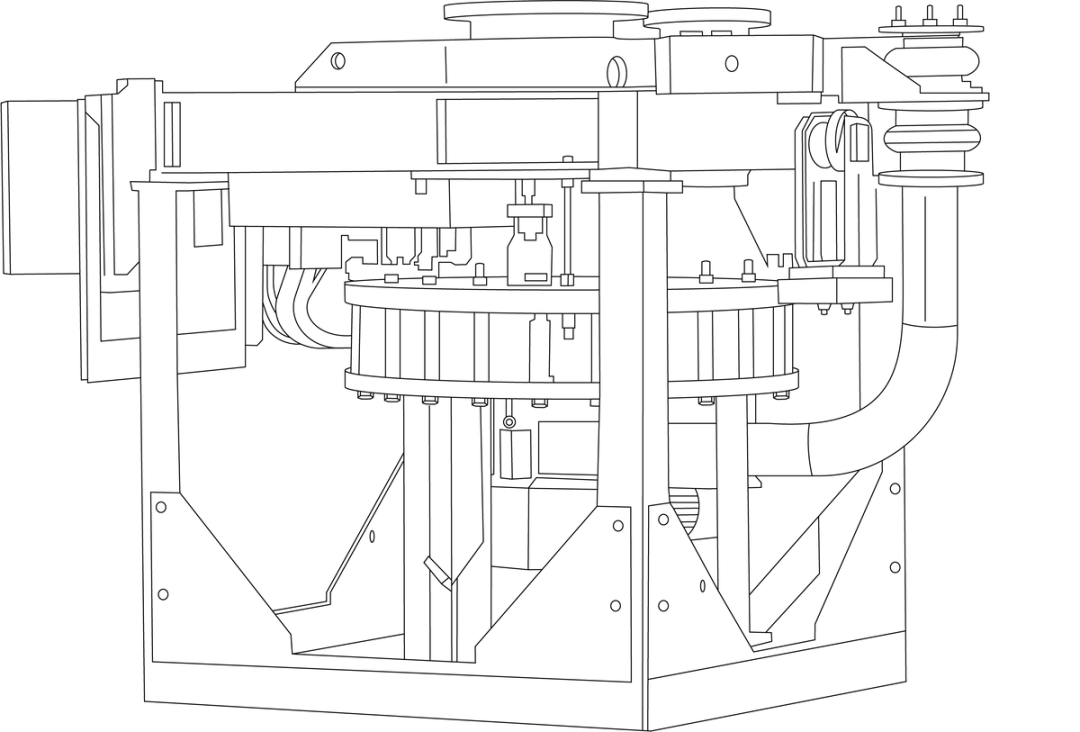

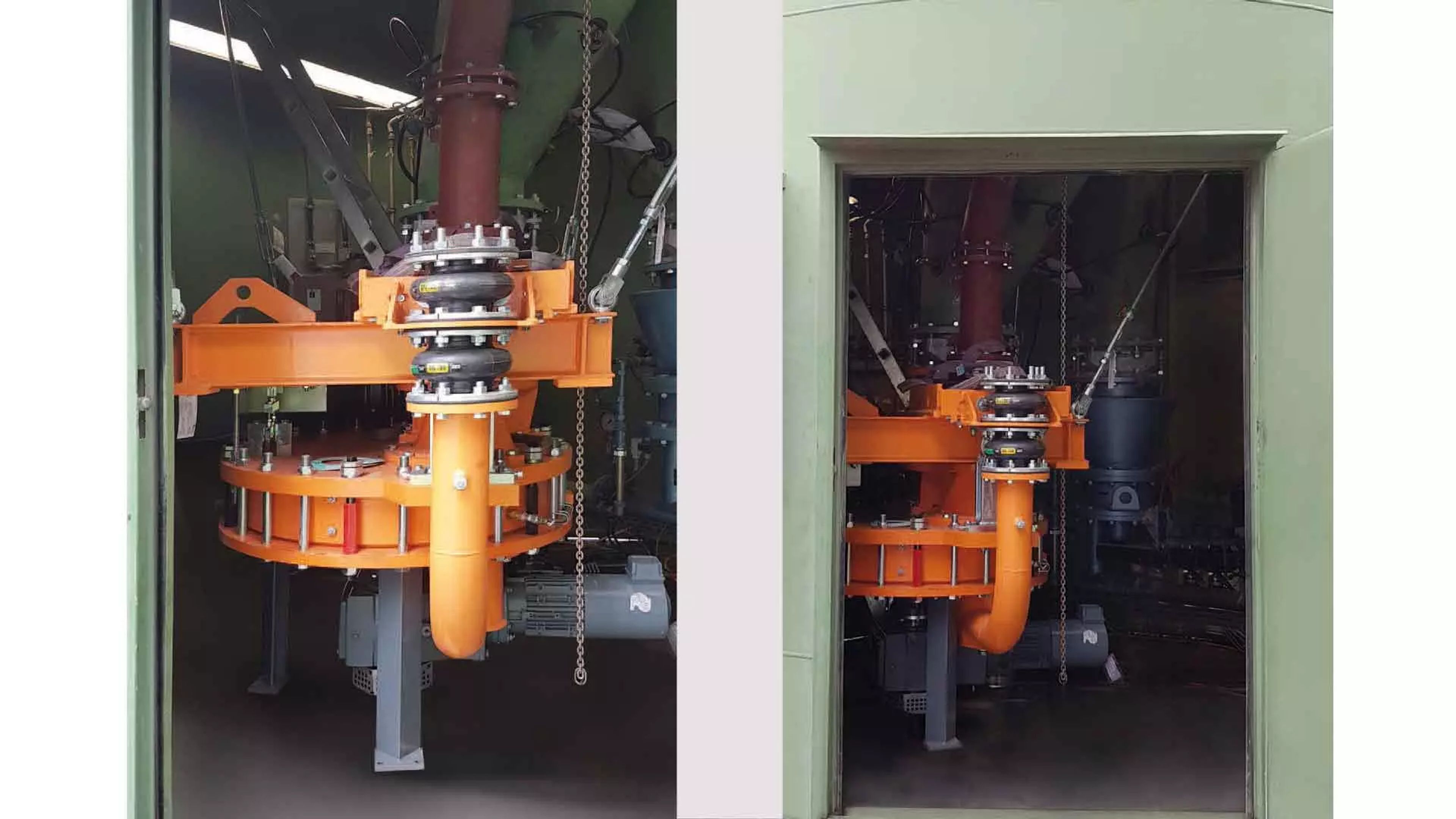

Unreliable coal dosing leads to an unstable process. For maximum fuel efficiency and low emissions levels, you need a precise and consistent coal feed. The PFISTER® SCF delivers. Thanks to the integrated dosing electronics, this smart coal feeder provides highly accurate and reliable gravimetric feeding of pulverized fuels to the burning process, including coal dust, lignite dust and petcoke. It has applications in the asphalt production industry, as well as heat and steam generation, where precise dosing of pulverized fuels is essential. Based on the industry-proven PFISTER® gravimetric rotor weighfeeder technology, the smart coal feeder is especially designed for dosing pulverized fuels in industrial environments. The sturdy design and integration of material extraction, weighing, dosing and material transfer into a pneumatic conveying line make this a compact system that is easy to integrate into existing facilities. Pulverized fuels are extracted directly from storage and fed pneumatically to the burner to support an optimal burning process.

Choose control: the PFISTER® SCF gives unparalleled dosing accuracy

Consistent and reliable fuel feeding

Traditional feed systems control dosing volumetrically. Their accuracy depends on the coal itself being homogenous, when the reality is vastly different. Your coal feed can’t be depended on to have the same density, the same calorific value or even the same lump size. PFISTER® rotor weighfeeders are gravimetric, meaning that the coal is weighed as it is dosed, so variations in size and density don’t have the same impact on dosing accuracy. The precision you can achieve with a PFISTER® rotor weighfeeder can have a huge impact on the economical and ecological operation of your plant. Constant, reliable coal feeding enables consistent, complete combustion with low emission levels.

Intelligent dosing control

ProsCon® prospective control is built in to all PFISTER® rotor weighfeeders. It’s an algorithm that anticipates the variations in flow rate caused by material density and flow ability by measuring the material’s weight before dosing. It then uses this measurement to calculate the precise speed of dosing to ensure a constant and stable fuel supply. Because fuel feed is based on weight rather than time, this gives very high accuracy over the short and long-term.

Compact system

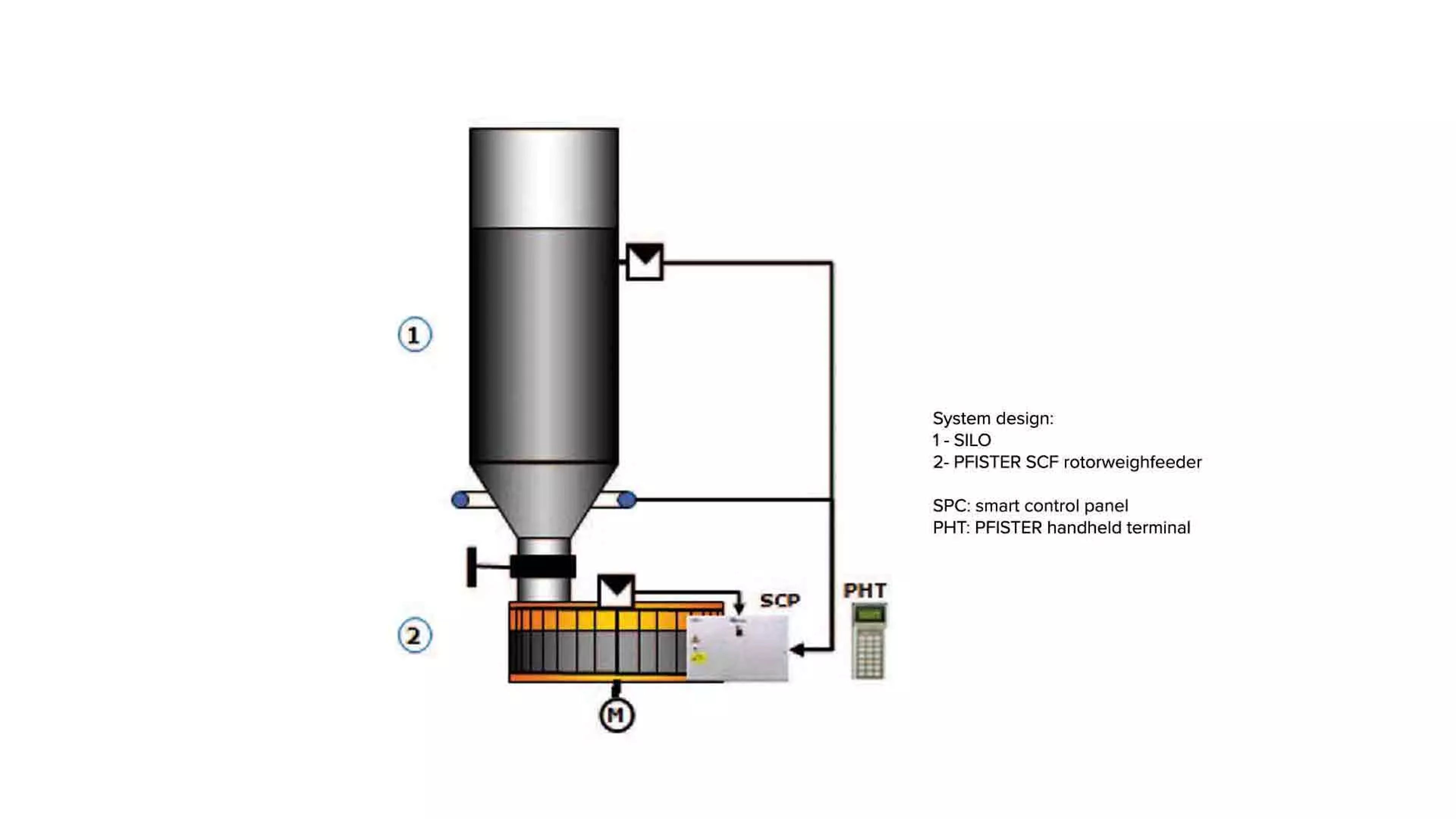

With material extraction, weighing, dosing and transfer to the pneumatic conveying line all contained in one system, the PFISTER® SCF is easy to install and maintain. Plus, it’s safe. System calculations provide optimal fuel transport to avoid material segregation in the pipes that could cause CO peaks.

User-friendly

Advanced systems shouldn’t be complicated to operate. We’ve equipped the PFISTER® SCF with an intuitive operator interface so that it’s very easy to operate. Flexible, reliable communication to the local plant control system is included as standard.

The accuracy you’d expect from a PFISTER® rotor weighfeeder

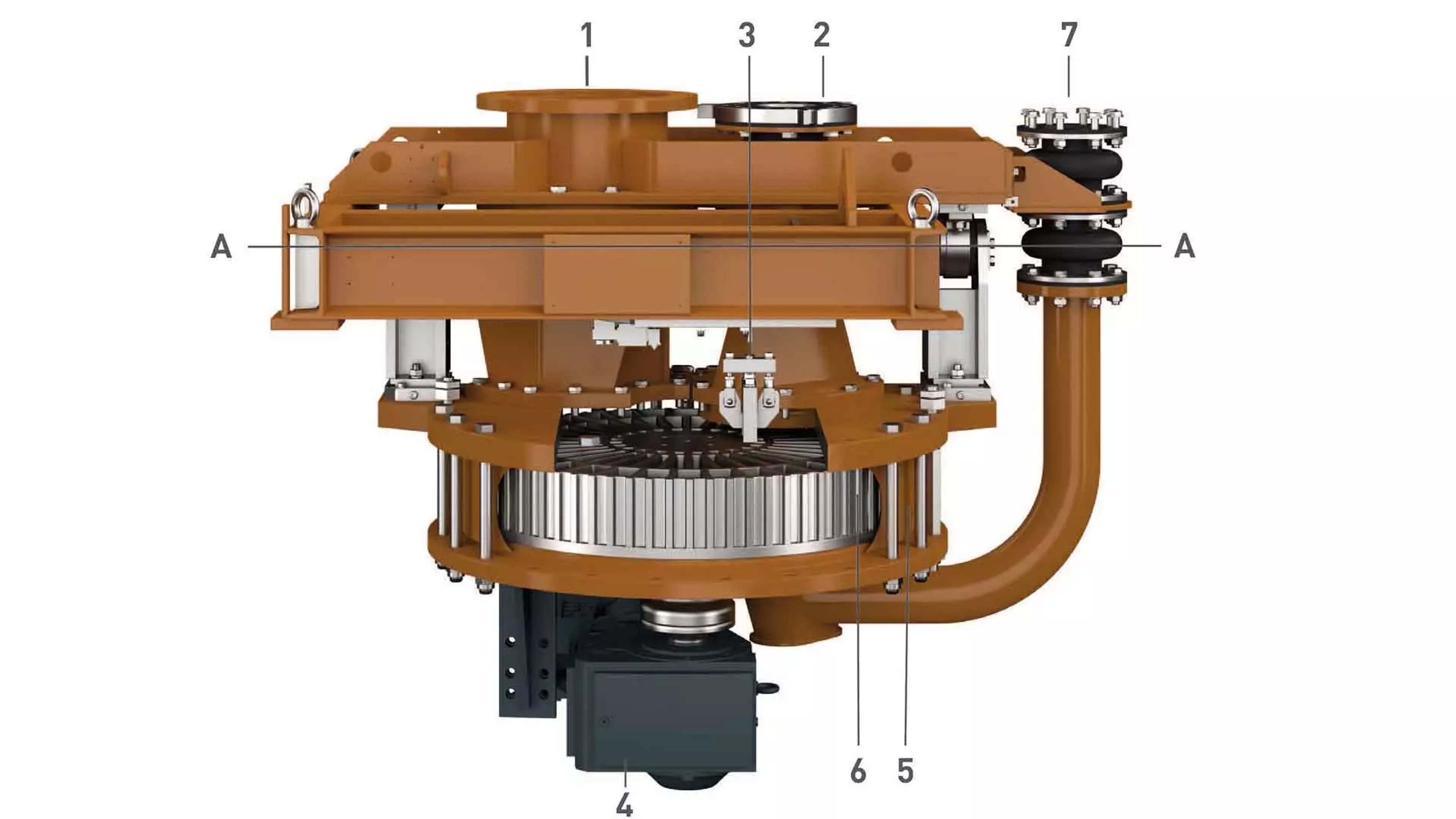

The PFISTER® SCF operates on the same principles as all PFISTER® rotor weighfeeders. The picture below illustrates the PFISTER® weighing and dosing principle.

Operating principle

Material is extracted out of the pre-hopper and is transported in the rotor chambers from the inlet (1) to the outlet (2). The rotor body is mounted on bearings that form a weighing axis (A-A). This axis is eccentric to the rotor shaft, and through the middle of inlet (1) and outlet (2). The third point is suspended at a load cell (3), which weighs the content in the rotor wheel gravimetrically. This means the rotor weigh-feeder measures the actual material load and is therefore a real scale. The measured gravimetric force provides information on the bulk material mass in the rotor weighfeeder before material discharge. This is used in conjunction with the position of the rotor wheel at the time of the measurement to determine the appropriate rotor speed. Put simply, the rotor slows with a high load and speeds up with a low load. This enables the rotor weighfeeder to discharge at the outlet (2) with a highly accurate mass stream.

Easy integration; constant communication

The PFISTER® data sampling device and controller is mounted at the feeder and collects all data in the field. Communication between the PFISTER® feeding dosing controller and the plant control system is possible via: Analog/Digital-Hardwired Interface; Serial Interface (ModBus RTU); or Network-Interface (ProfiBus DP/Device Net/or others).