A powerful, smart mill suitable for a range of sample applications

What we offer

Dependable ring mill pulveriser

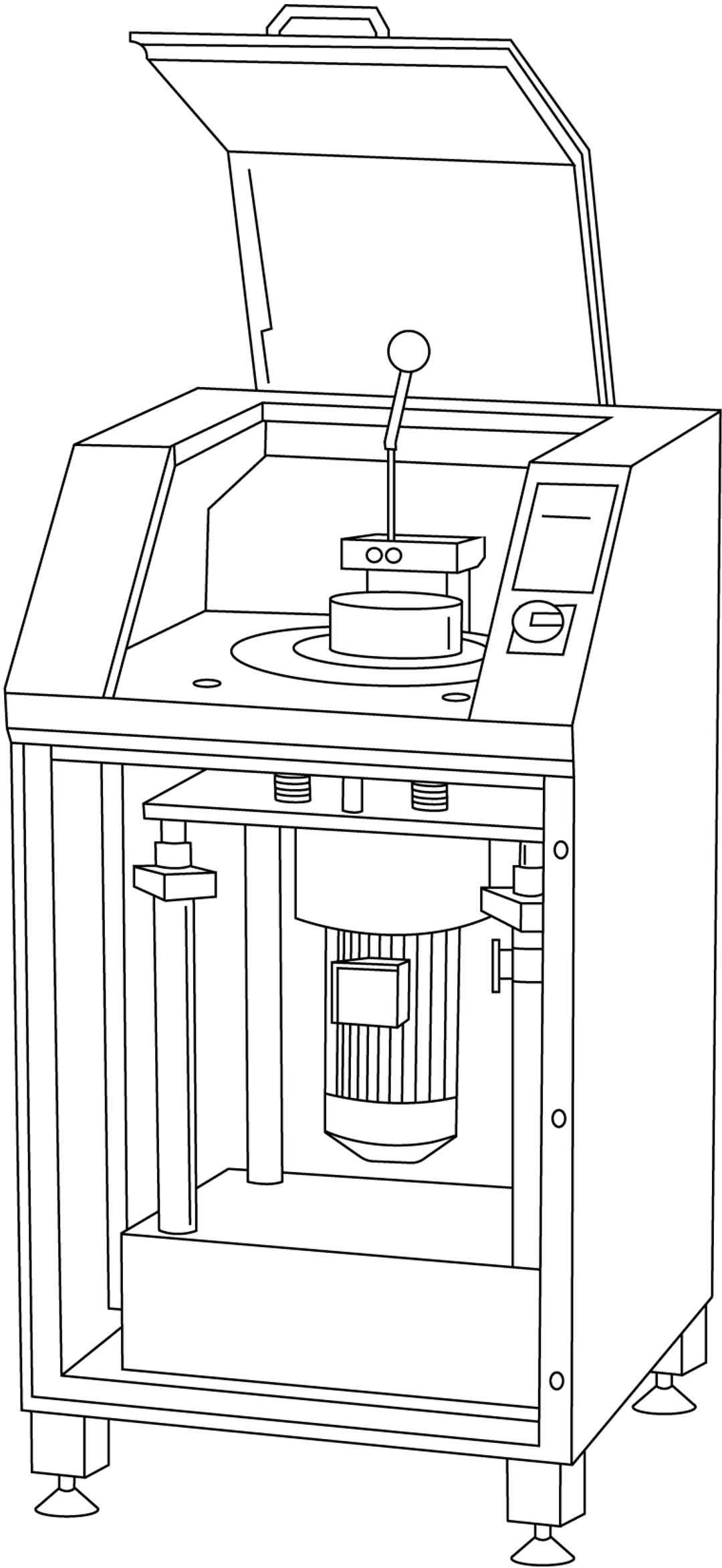

The QCX M100M Manual Mill is a manual disc mill that is engineered to provide high productivity and accurate results. It is an adaptable unit that easily handles a range of sample materials, such as clinker, slag, ores, minerals and raw materials. It is versatile and the human-machine interface (HMI) makes it easy to use – we guarantee your staff will appreciate its ease of operation. The operator has 16 processing programmes available to guide them through the preparation procedure, ensuring human error is a minimal risk.

Easy-to-use manual disc mill for x-ray sample preparation

The QCX M100M Manual Mill is a simple machine with high functionality.

It's easy to use

The grinding vessel is located at an ergonomically correct height and the lid is closed using a bearing guided level making it easy for the operator to place sample material in the grinding vessel.

The grinding chamber is soundproof

The soundproof nature of the grinding chamber makes it compliant with today’s strict regulations and a pleasure to use.

It is compatible with the QCX P40M Pellet Press

Its compatibility with the QCX P40M Pellet Press makes it the ideal set for x-ray sample preparation.

It offers a range of advanced safety features

The intelligent design prevents the mill from starting if it is not correctly clamped. The cover on the machine is locked with a safety switch during operation, meaning it cannot be accidentally opened, thereby improving worker safety.

A versatile pulveriser that offers proven performance

QCX M100M Manual Mill

This manual disc mill is used for x-ray fluorescence (XRF) and x-ray diffraction (XRD) sample preparation. You will appreciate its ability to finely pulverise and this makes it a great choice for a range of sample materials including minerals, slag, ores, clinker and raw materials. It is easy and safe to operate and is ergonomically designed for the operator’s comfort, a big tick for workplace, health and safety. Once the sample material is placed in the grinding vessel, the operator can choose one of 16 processing programmes. Via the HMI, the programme guides the operator through the correct preparation procedure. Its intelligent design is perfect for XRD analysis, where a soft grinding method can be applied. Various grinding vessels are available for different applications, including chrome steel or tungsten carbide. All parameters are password protected and can be entered in individual sample processing programmes. On completion of the cycle, the grinding vessel can be easily removed and prepared for the next preparation cycle, making it as efficient as it is effective.