Integrated solutions for cement packing, palletising and dispatch

Production lines keep expanding. So at the end of the line, there’s more product than ever to be filled into bags, palletized and dispatched. If your packing plant can’t keep up with your production line, you’ve got a problem.

We create high capacity, fully automatic equipment that evolves with your demand. Our modular systems can be easily expanded, giving you the flexibility to uprate your packing plant when needed.

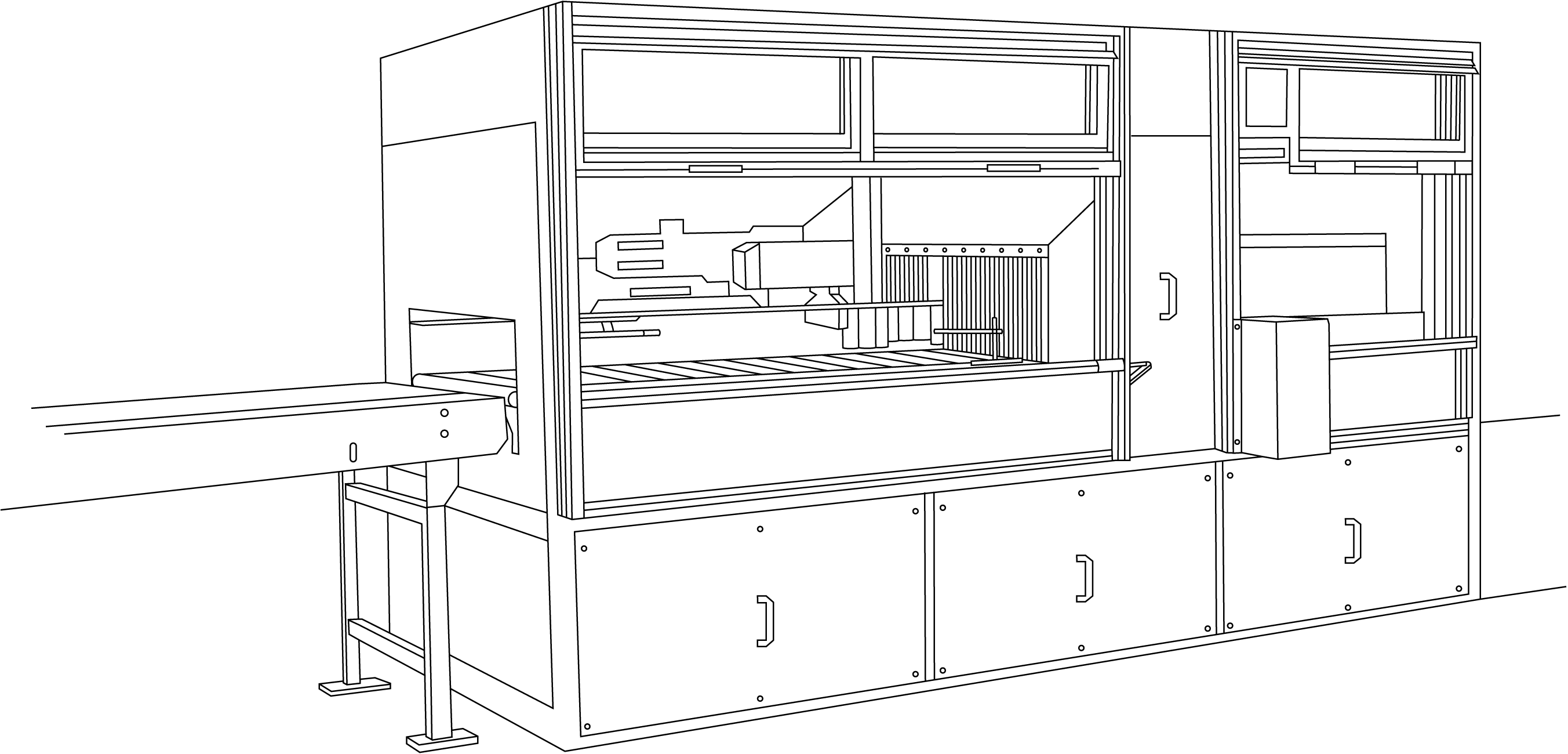

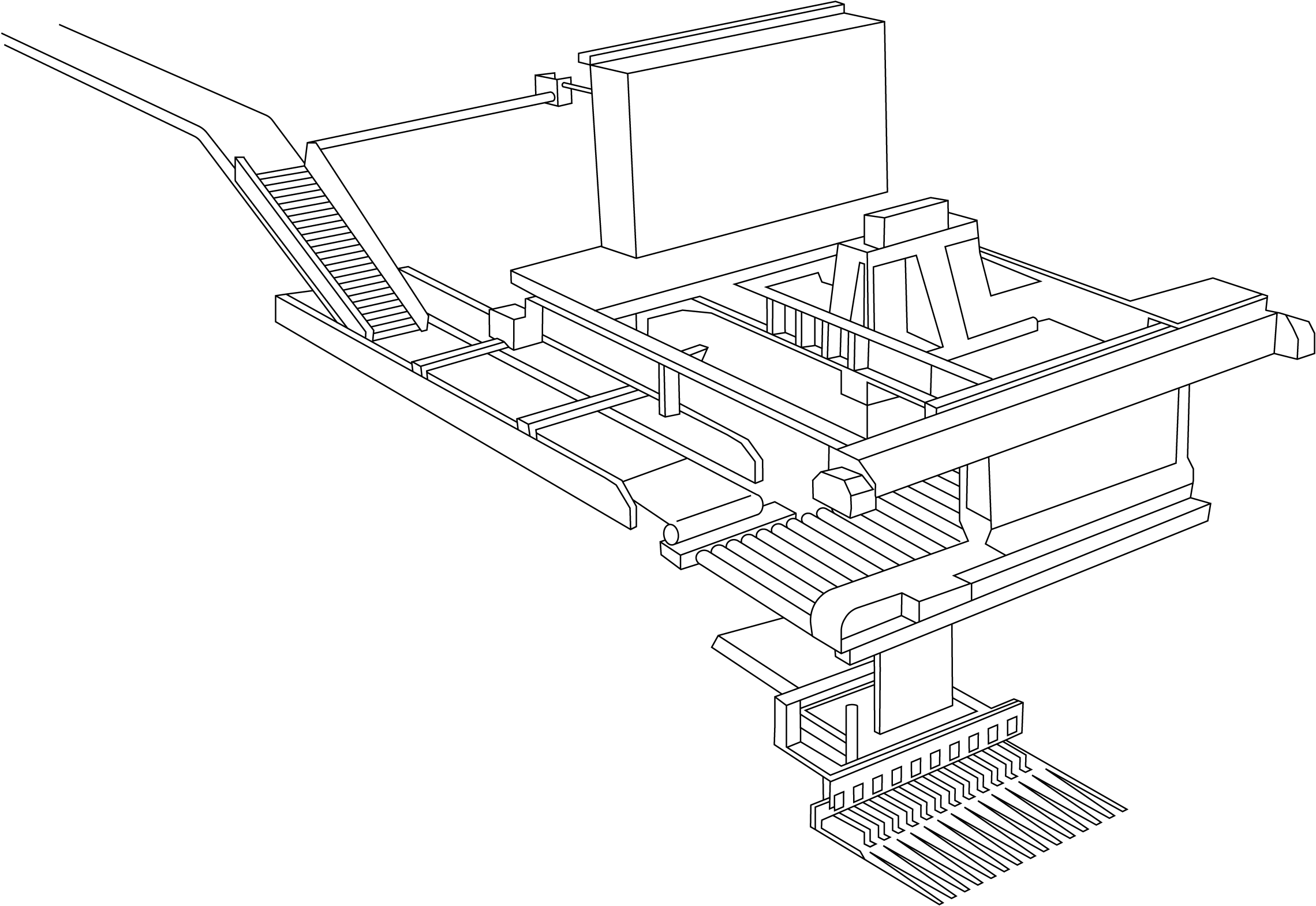

Our Ventomatic® brand designs and produces complete automatic lines for full bag handling, including:

- Packing lines

- Palletizing lines

- Truck and wagon loading lines

- All related ancillary equipment, from silo extraction to dispatch

Full engineering services are provided by our qualified technical staff, and after sales service is taken care of by our global network.

We bring more than 50 years of experience to the table, and pour it all into creating energy-efficient, productive and reliable packing and dispatch solutions for the cement, building materials, chemical and fertilizer industries. We cater for various bag sizes, bag sealing options, and a wide range of powdery and granular materials. You can also choose how you want your stacks – shrink-wrapped, stretch hood, pallet or no pallet. Our solutions are built around market requirements, so we can deliver a system that works for you.

Ventomatic® logistic solutions are recognised on the international market, not only for new installations, but also for the modernisation and enhancement of existing facilities. All equipment can be integrated into standard existing packing/loading installations.

Improve the efficiency of your packing plant with VENTOMATIC® Plant Integration Interface

You can connect your DCS, MES or ERP systems to one of the three levels of access with a simple communication module offered in option on all Ventomatic® equipment.

What you get is a detailed picture of your equipment:

- LEVEL 1: Ready-Run-Faults status

- LEVEL 2: Level 1 + Statistical data, alarms and message list

- LEVEL 3: Level 2+ Remote commands like Start-Stop, alarms reset and recipe selection

downloads

2015 International Cement Review case story - Ventomatic® packing and palletizing plant

30.05.2024 |

365.93 KB |

English

2016 World Cement article - Ventomatic® trends in logistics

30.05.2024 |

2.32 MB |

English

2017 World Cement case story - Ventomatic® packing and truck loading plant

20.09.2024 |

600.63 KB |

English

_CL_Ultrasonic_Valve_Bag_Sealing_System.png?w=3840&q=80&auto=format)

_automatic_truck_loaders.png?w=3840&q=80&auto=format)