Pneumatic conveying pipe for abrasive materials

What we offer

Pneumatic conveying pipe - low on maintenance, high on quality

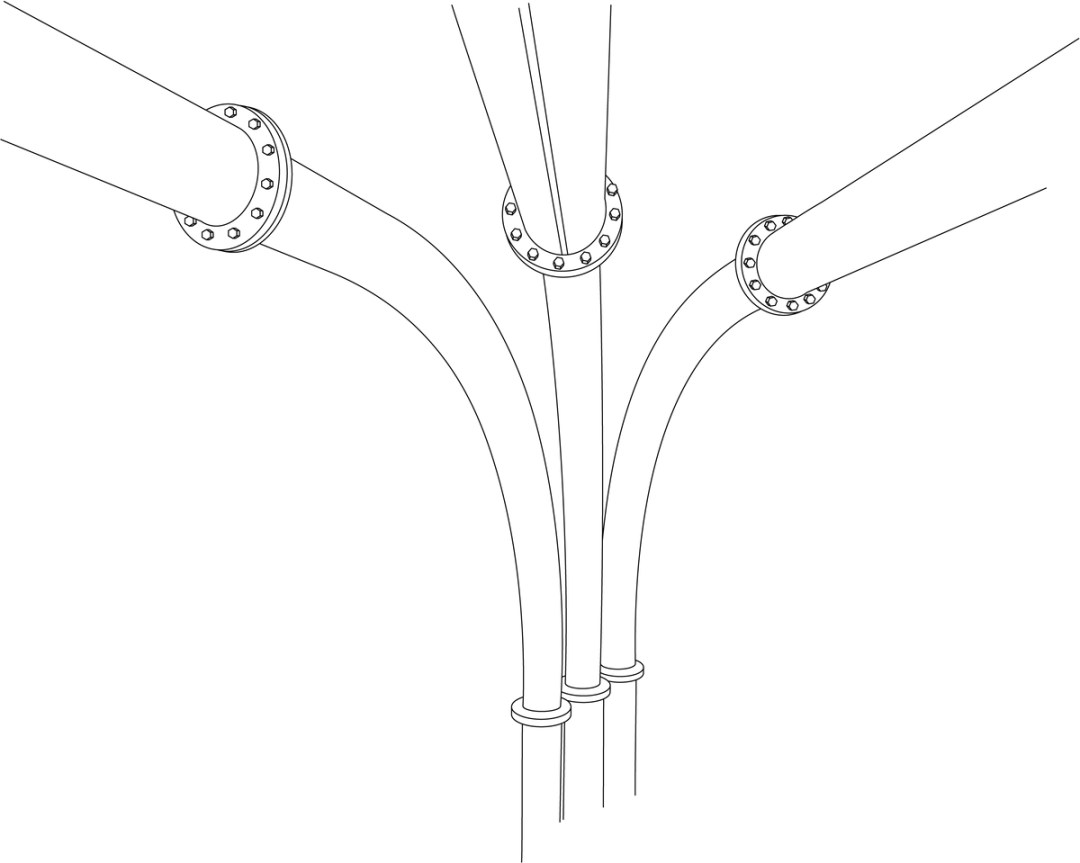

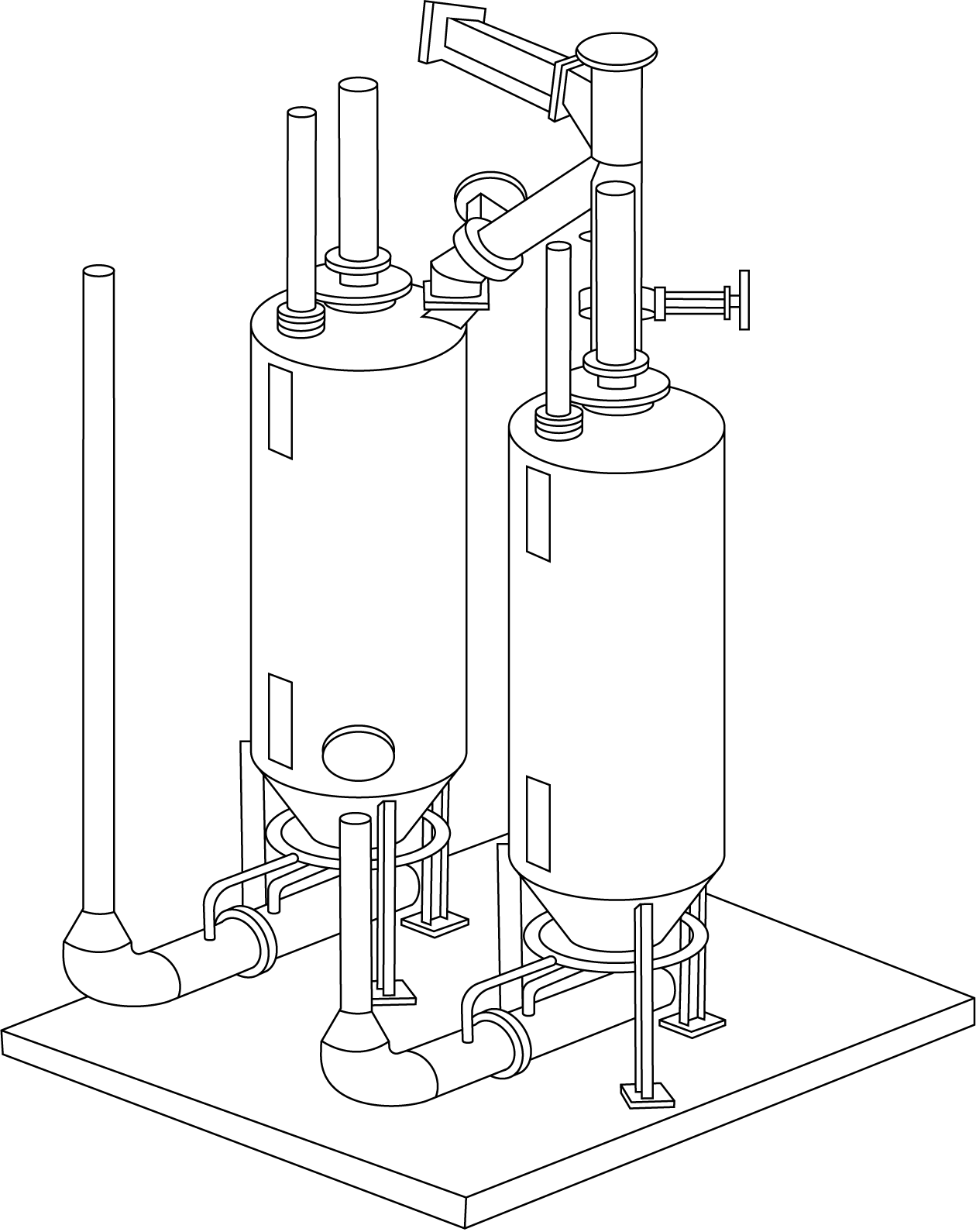

When you're transporting any materials through your pneumatic conveying system, you have two concerns: efficient delivery and safe transport. Abrasion has a negative impact on both. When the abrasive materials rub against the interior of the pipeline, they cause wear that could ultimately put that pipeline out of operation. Meanwhile, that friction also stresses the materials – and in the case of polymer plastics can give rise to dust, streamers, angel hair and other prettily named but unwelcome phenomenon. Our abrasion-resistant pipeline fittings are designed to prevent both of these problems. The diamond-shaped pipe elbow interior finish was developed for durability. It resists abrasion and dramatically reduces the occurrence of fines and streamers. And because we know that process plants come in all shapes and sizes, the fittings are available in a range of configurations to meet your pipeline layout needs. Our abrasion resistant ceramic pipe fittings are manufactured from 450-Iron for all kinds of abrasive bulk materials. We also have cast aluminum pipe fittings range developed especially for transporting plastic pellets

Materials typically handled include:

- PVC

- Polyethylene

- Polypropylene

- Nylon

- Polyester

- Vinyl Acetate

Aluminum pipe fittings that are built to last

Long-lasting design

Every time you have to maintain a pipeline, you’re spending money on resources and losing money on production. Our abrasion-resistant pipeline fittings cut maintenance requirements, giving you the reassurance that your abrasion resistant ceramic pipe fittings won’t let you down. Reduced downtime. Reduced resources. Reduced costs. It’s a win-win-win.

Better for your product

As well as your pipeline, you also have to consider the safety of your product. With abrasion resistant ceramic pipe fittings, the incidence of fines and streamers developing in your pipeline is significantly reduced. Your product will arrive at the end of the pipeline in optimum condition.

Customisable connections

Every pipeline is slightly different. Our aluminum elbow pipe fittings cater to that with a wide range of fitting sizes, bend angles and end connection configurations. There is something for everyone.

Cast iron pipe fittings that meet the needs of your application

Our abrasion resistant ceramic pipe fittings are ideally suited for pneumatic conveying systems handling abrasive materials. These fittings are cast throughout their entire thickness with FLSmidth 450 abrasion-resistant cast iron with 475-550 Brinell hardness.

Transporting abrasive bulk materials

Our cast iron pipe fittings are ideally suited for pneumatic conveying systems handling abrasive materials. These fittings are cast throughout their entire thickness with FLSmidth 450 abrasion-resistant cast iron with 475-550 Brinell hardness. Various configurations are available to suit pipeline layouts. • Bend radii are nominally three times pipe diameter. • Fittings are generally available in nominal diameters ranging from 3 inches to 12 inches (76mm to 300 mm) in size. • Wearbacks are available as integral castings or replaceable bolted units. • Standard end style is plain end for compression type couplings and/or flanged adapters. Cast flanged ends are also available in certain configurations.

Fittings for plastic pellets

For conveying polymer materials, we have developed a special range of cast aluminium fittings. These are cast of either 356.0 - T6 or SR319.0 - T51 (75-85 BHN). The internal surfaces have a diamond pattern finish that is proven to reduce wear and streamers. Again, these fittings are available in configurations to suit your process and pipeline layout. Standard end styles are plain end for compression type reducing couplings, flanged (150 lb. std.) and Victaulic® groove ends available. • Sizes: 3”, 4”, 5”, 6”, 8”, 10”, 12” (75 mm, 100 mm, 125 mm, 150 mm, 200 mm, 250 mm, 300 mm) • Bend Angles: 90º, 60º, 45º, 30º

_vertical_conveying.png?w=3840&q=80&auto=format)