Improve your open gears with reliable pinions that function smoothly

What we offer

Tailor-made pinions that round up your open gears

We’ve spent decades refining the design and manufacturing of our gear pinions to ensure that they work hand-in-hand with girth gears. Custom-made to meet your specific requirements, our pinions use the perfect combination of material, hardness and finishing – contributing to the long service life of your open gear. By continuously investing in technology and knowledge, we deliver improved pinion technology – meeting your needs today and tomorrow. Pinions are as varied as their applications. Our pinion designs include: Self-aligning, Spur, helical or double helical, Bored and integral, Forged alloyed steel, Through-hardened, quenched and tempered, Carburised and ground, Induction-hardened, and Nitrided.

Engineered for success in your open gears

Our teams of engineers carefully consider how to implement the required tooth flank modifications for the gearing of various pinions with new installations. These considerations include profile and lead correction – ensuring that our gear pinions are fit-for-purpose and deliver maximum output with minimal noise disruption. Through precise manufacturing techniques, we implement profile and longitudinal modifications for pinions as required by your mill or kiln drives.

We can also re-engineer pinions that are already installed. If you need to replace existing pinions with ones that have a higher performance or different speed, we know how to optimise the new gearing to meet your new requirements.

Heat treatment and high standards

As we have developed, improved and patented several heat treatment processes, we can safely call ourselves leaders in the field of heat treatment. Our modern heat treatment facilities ensure the best material quality and characteristics, producing dependable top-notch pinions.

Stringent quality control procedures throughout our manufacturing processes let you rely on our gear products. We use strict testing methods including NON-destructive, ultrasonic, magnetic particle and penetrant testing along with NDT-QA inspection to guarantee faultless parts. Our gear components comply with applicable international standards including:

UNI EN ISO, AWS, ASTM, ASME, and DIN.

Made for your requirements today and tomorrow

Working to your precise needs, our highly-experienced engineers use the latest finite elements modelling software to design and engineer pinions for open gears that fit your specifications. Our modern production sites and continuous advancements ensure that our pinions meet your needs now – and into the future.

Pinions you can rely on for long-lived performance

Long service life

Our high-quality materials, modern heat treatment and exacting standards produce pinions for open gears that go the distance. The longevity of our gear pinions contributes to easy maintenance and smooth operations for your mill and kiln.

The diversity to fulfil your demands

The wide variety of our gear pinion designs allows them to function in a wide range of applications. Our range of materials, finishings and features gives you precisely the right pinions to keep your open gears at optimal function.

Made to order – and to match your needs

We produce pinions that meet your precise needs by using our state-of-the art manufacturing processes. Through reverse engineering, we can also build replacement pinions that fit your existing configuration or even improve your process with higher torque capacity or different speed.

Well-designed, well-made pinions – tailored for your mill and kiln

We continually invest in our modern production sites to guarantee our gear pinions use the latest manufacturing techniques. By leading the field in advancements such as heat treatment, we ensure durable components that stand up to your heavy-duty needs.

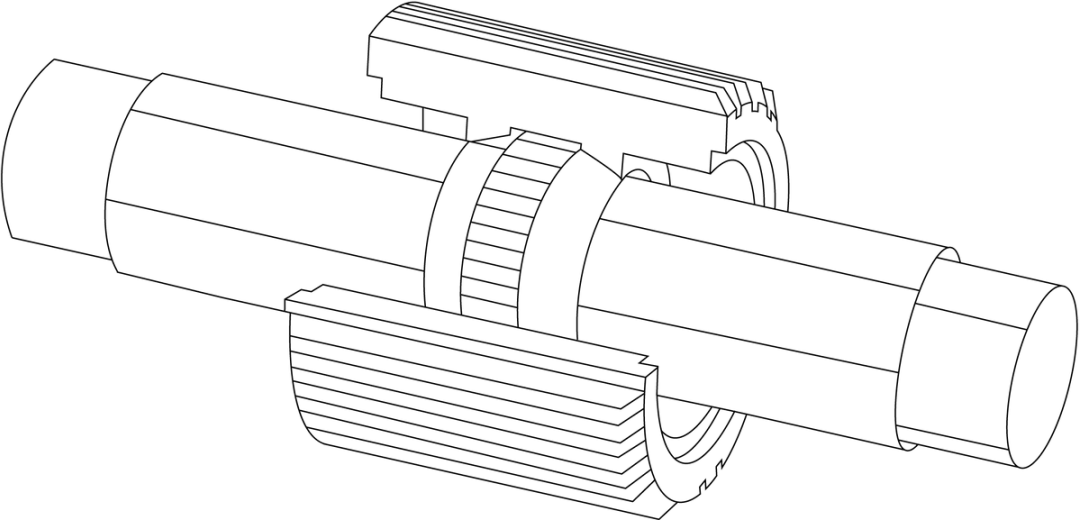

The complete drive system

Ball and grinding mills, kilns and dryers are often operated with open gears. Based on your application, available space and other individual parameters, our gear solutions power your equipment – getting the highest performance from your process. The classic open gear arrangement includes the main motor, an intermediate gear unit for speed reduction and the pinion, which meshes with the girth gear. Our standardised product range, in combination with individually-designed girth gears and pinions, allows us to supply a customised power train for your specific application. Pinions are available in a solid, on-shaft design, where the gearing is integrated as part of the shaft, or as bored, assembled pinion with shaft. The latter permits a higher-grade material for just the gearing area – letting us optimise the pinion to meet your unique needs. We recommend using self-aligning pinions for high-torque transmission situations. The spherical bearing used between the shaft and the bored pinion allows the toothing to slightly swing – enabling the self-aligning pinions to compensate for minor run-out deviations of your mill or kiln. To guarantee the correct match in hardness between pinion and girth gear, we take into account the meshing assembly and modify the carburising and case-hardening process accordingly. We produce wear-resistant components with the maximum lifespan for both pinions and girth gears.

Backed by experience and know-how

While our modern manufacturing processes are impressive, it’s really our highly-skilled engineers and operators who make our pinions top-class. Our engineers and machine operators are trained in sophisticated engineering software, allowing them to create high-quality open gears made from different materials that meet your precise specifications. We can manufacture all geared components of the entire power train or individual components depending your needs. Based on engineering analysis and many years of experience, we can also propose design improvements to increase part reliability – delivering smooth operations for your mill or kiln long into the future.