Docksider Ship and barge unloaders backed by experience

What we offer

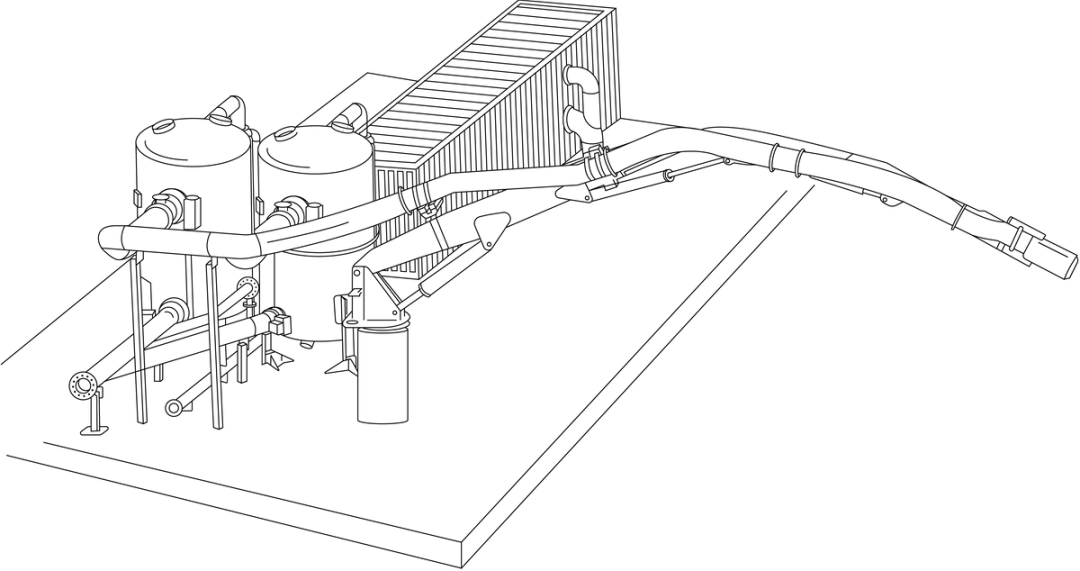

DOCKSIDER™ Pneumatic Ship Unloader

Docksider Ship Unloaders are custom-designed for your specific terminal application, with state-of-the-art technology developed by FLSmidth Cement exclusively for the ship and barge unloading industry – offering unequalled performance, reliability and durability. For high-capacity applications, a separate vacuum filter receiver allows for continuous airflow and faster material transfer. Multiple discharge options, including pressure tanks, feeders and rotary valves allow for conveying a wide range of dry-bulk materials – even abrasive products such as alumina and coarse limestone. The system can even discharge through a Fuller-Kinyon® Pump – allowing for simple, low-pressure pneumatic conveying, or to provide a durable vacuum seal for material transfer to a dock belt conveyor.

Robust. No dust. Smart ship unloaders from FLSmidth Cement

Modern PLC control systems

Functions automatically using easy-to-navigate touchscreens. The control systems have built-in features to monitor operational status, process settings, historical production data, alarms and maintenance requirements. It can even simulate operating conditions and test the components and sub systems, ensuring that your unloader is ready to work when you are.

Clean operation

From the time it enters the vacuum nozzle to the time it reaches its storage destination, the material is fully encapsulated in a system of piping, hoses and vessels – making Docksider Ship Unloaders among the most environmentally-friendly transfer systems in the industry. The filtration system is either integral with the transfer kettles or in a separate filter vessel (for dual-pipeline or extra-high capacity applications). Pleated cartridges provide optimal cloth area in a compact design, and jet-pulse cleaning and a PTFE media coating offer maximum durability and efficiency.

Performance you need

GUARANTEED! With the industry’s continuing demand for increased capacity and for conveying multiple and diverse materials, constant research and development is critical. Only FLSmidth Cement’s Pneumatic Transport group has a laboratory capable of analysing various materials – over 160 to date – for the sole purpose of identifying the optimal design for their movement through a pneumatic conveying pipeline. Every Docksider Ship Unloader is backed with a performance guarantee – and FLSmidth’s global reputation for superior quality and exemplary customer service.

What we offer

Flexible, high-capacity ship unloading, designed to suit you

Starting with a range of four basic sizes, FLSmidth Cement can supply the right Docksider Ship Unloader for any terminal – whether you’re unloading river barges or Handymax Bulk Vessels, and whether you’re conveying to an adjacent belt conveyor or through a 1200-meter (4000-foot) pipeline.

Video

DOCKSIDER ship unloaders are custom-designed for your specific terminal application, with state-of-the-art technology developed by FLSmidth Cement exclusively for the ship and barge unloading industry.

Featured posts