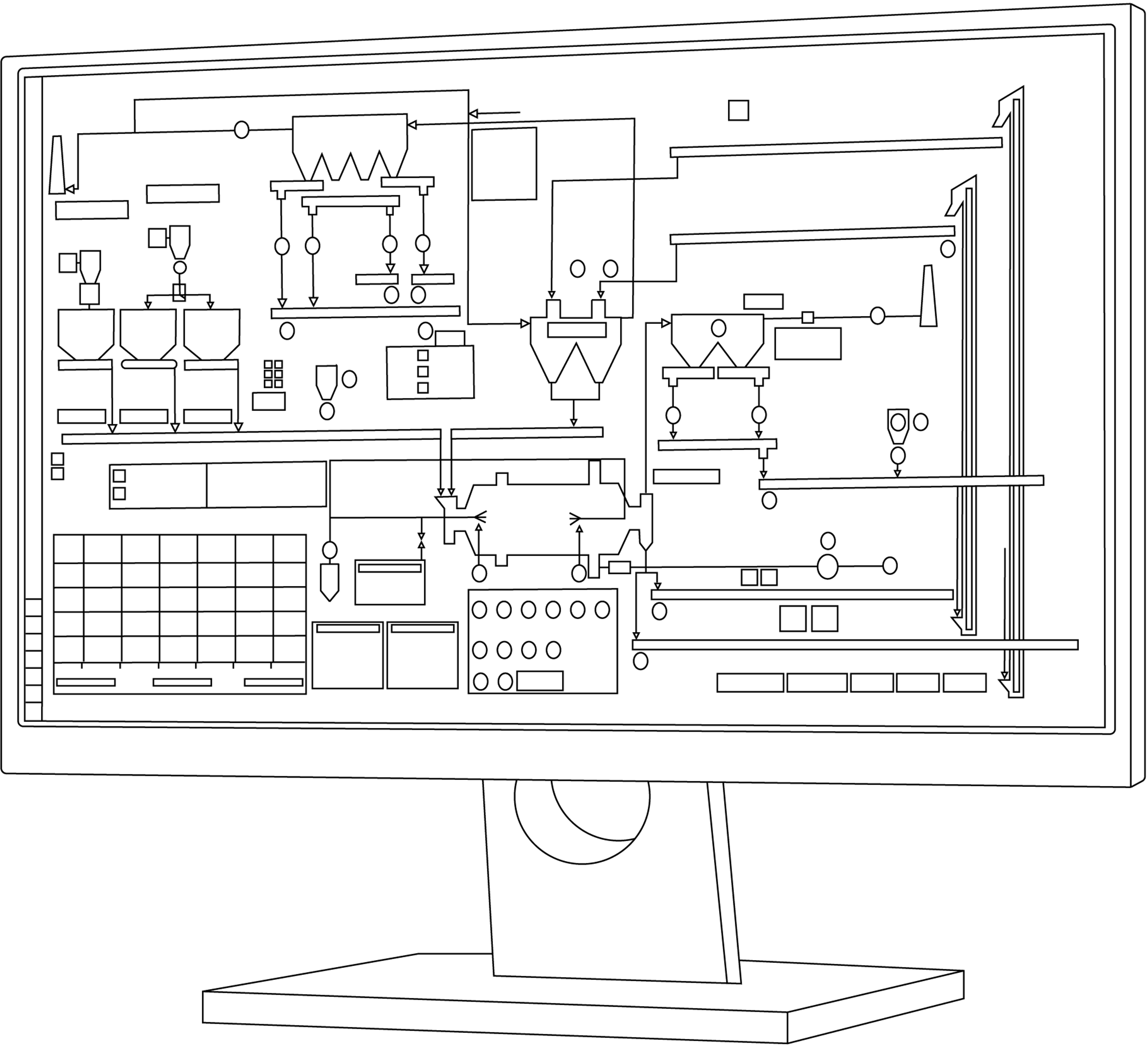

Our ECS/ControlCenter™ Software Platform makes it happen effectively. It is the basis for our digital process and machine control solutions.

Whether you would like to automate your equipment, a process area, or your complete plant, being supplied by FLSmidth or third-party machinery, we have the control solution to make it happen – all powered by our ECS/ControlCenter™ Software Platform.

Our ECS Process Control Solution takes you up a level. By allowing complete and reliable automated control of your plant, it optimises performance, ensuring you are operating at your maximum potential. It also supports quicker and smarter troubleshooting of faults by your operators and maintenance engineers, reducing downtime and lost production, so you can sleep better at night. And it provides the tools, data and connectivity needed to unlock the value of Industry 4.0.

Our ECS Product Control Solution is the integrated OEM standard for most FLSmidth-supplied equipment, and ECS Machine Control Solution can also control any third-party machinery in your operations. Both allow you to fully automate the equipment, ensuring you get the most from its functionality, while eliminating the risk of operator error and becoming digitally prepared for the future.