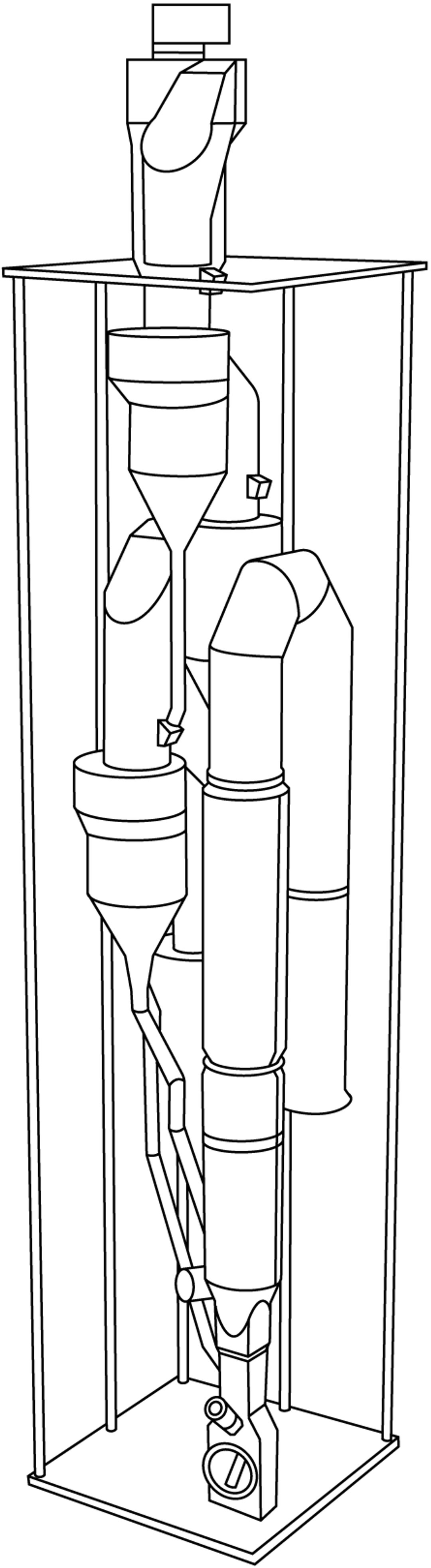

In-Line Calciner Preheater System for cement plants

What we offer

Our customisable preheater calciner cuts emissions, boosts efficiency

Getting the right preheater calciner system will have a big impact on your cement plant’s operational efficiency, emissions, and ability to burn alternate fuels. Our In-Line Calciner Preheater System, first introduced in 1976 and continually updated and improved, will help you meet emissions requirements and optimize fuel and power consumption. It’s easy to operate, reliable, and offers the lowest NOX emission available, thanks to our unique high-temperature reduction zone. CO emission is low too, because our mid-calciner notch and specially-designed exit duct provide superior mixing and combustion. Our In-Line Calciner is suitable for firing both traditional and alternate fuels. And operation is easy, with single entry locations for both the calciner fuel and tertiary air. That’s why our In-Line Calciner Preheater System is the standard for pyroprocess systems today.

Effective emissions control with optimised fuel and power consumption

Easy to operate

Single-entry location of calciner fuel and tertiary air makes this preheater calciner system easy to operate

Highly reliable

First produced in 1976, the FLSmidth in-line calciner preheater system is the standard for pyroprocess systems.

Flexible fuel usage

Suitable for firing both traditional and alternate fuels

Reduce NOX and CO emissions

Lowest NOX emission from unique high-temperature reduction zone, with simultaneous low CO emission

In-line calciner with capacity range up to 14,000 t/d, 6 cyclone stages

The FLSmidth In-Line Calciner Preheater System offers a full capacity range for today’s plants, up to 14,000 t/d or more. It can be built with single or multiple preheater strings with up to 6 cyclone stages. The ratio of firing in the calciner is 55-65% of total, while achieving a calcination rate at the kiln inlet of 92-95%. For buildup and chemistry there is an allowable bypass of kiln gas of 0-60%. If you are seeking bypass of kiln gas of up to 100%, a special ILC-I version is required.

.jpg?w=1080&q=80&auto=format)