Feeding and dosing coarse and hot materials with precision

PFISTER® TRW rotor weighfeeder

Gravimetric feeding for optimum precision, whatever your material

Your process needs accuracy and consistency to deliver optimum performance. But dosing coarse materials can make this difficult to achieve. Traditional volumetric weighing systems can’t cope with the variability of the feed, while the wear caused by handling abrasive and hot materials can give you endless maintenance headaches. The robust design of the PFISTER® TRW rotor weighfeeder is ideal for metering coarse and hot bulk materials such as clinker, pre-ground cement, limestone and gypsum with consistency and precision. Since the material only comes into contact with the steel rotor, wear is negligible. And as a complete system comprising material extraction, weighing and dosing, it’s easy to operate and very reliable. The gravimetric feeding technology enables high levels of accuracy and consistency, regardless of the variability in the materials. Our ProsCon® prospective control advanced weighing electronics anticipates changes in the feed and adjusts the rotor speed accordingly to ensure the output is always the same. Feed rates of up to 400 t/h are possible, as well as material temperatures up to 200˚C.

Outstanding reliability. Long service life. Accurate, every time

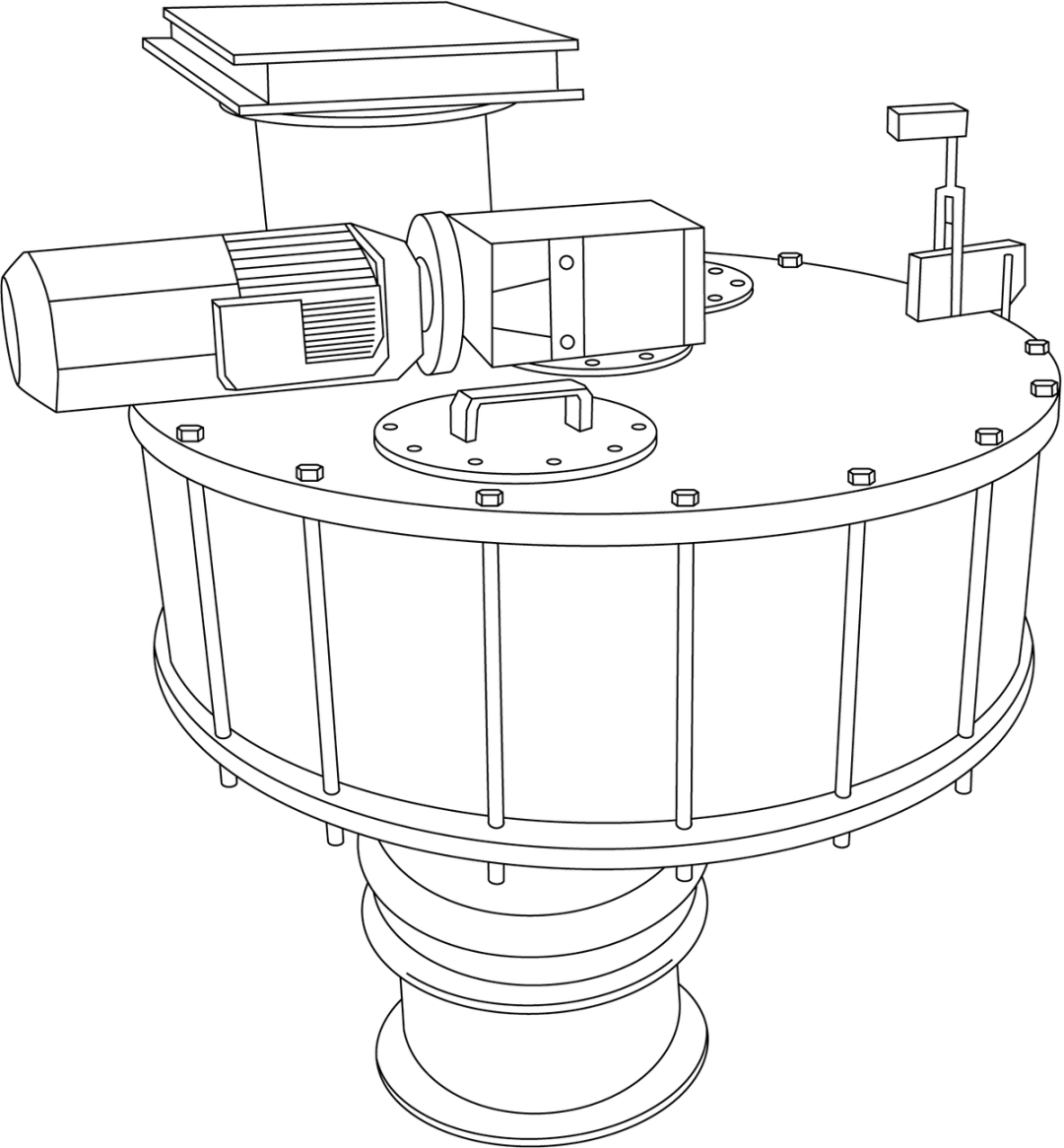

Good engineering shouldn’t be overly complicated. We’ve designed the PFISTER® TRW rotor weighfeeder to be as straightforward as possible, so that it delivers the utmost performance and availability over a long service life. Minimal moving parts. Slow-moving rotor. The material is only in contact with steel, minimising wear. And you can be sure that the little maintenance required will be simple, since all the measuring parts and drives are accessible from the outside. Extraction, weighing, feeding and dosing are all included in one enclosed system. There’s no clean-up since there can be no spillage.

Precise, but flexible

As well as its reliability, one of the main advantages of the PFISTER® TRW is the accuracy it offers compared to other systems. That’s because all of our rotor weighfeeders use ProsCon® prospective control, which adapts to changes in the feed to ensure consistent and highly precise dosing, even of coarse and hot materials. Short-term and long-term accuracy is assured, giving you a more efficient and consistent operation. You can also choose a pre-hopper equipped with load cells to enable online calibration for easily repeatable measurements. It doesn’t even matter if you’re not operating at your usual feed rate. High levels of accuracy are guaranteed from 10% - 100% of your maximum feed rate. And quick adjustments are simple, too. ProsCon® ensures virtually no reaction time in changes of the feed rate – without loss in accuracy. All our rotor weighfeeders are based on advanced mechatronic design. But that doesn’t mean they are hard to use, or even to integrate into your process. The PFISTER® TRW is easy to operate. Communication with the local plant control system is reliable and flexible. It is designed to work in almost all processes – just tell us about your application and we’ll work out the details.

How does the PFISTER® TRW work?

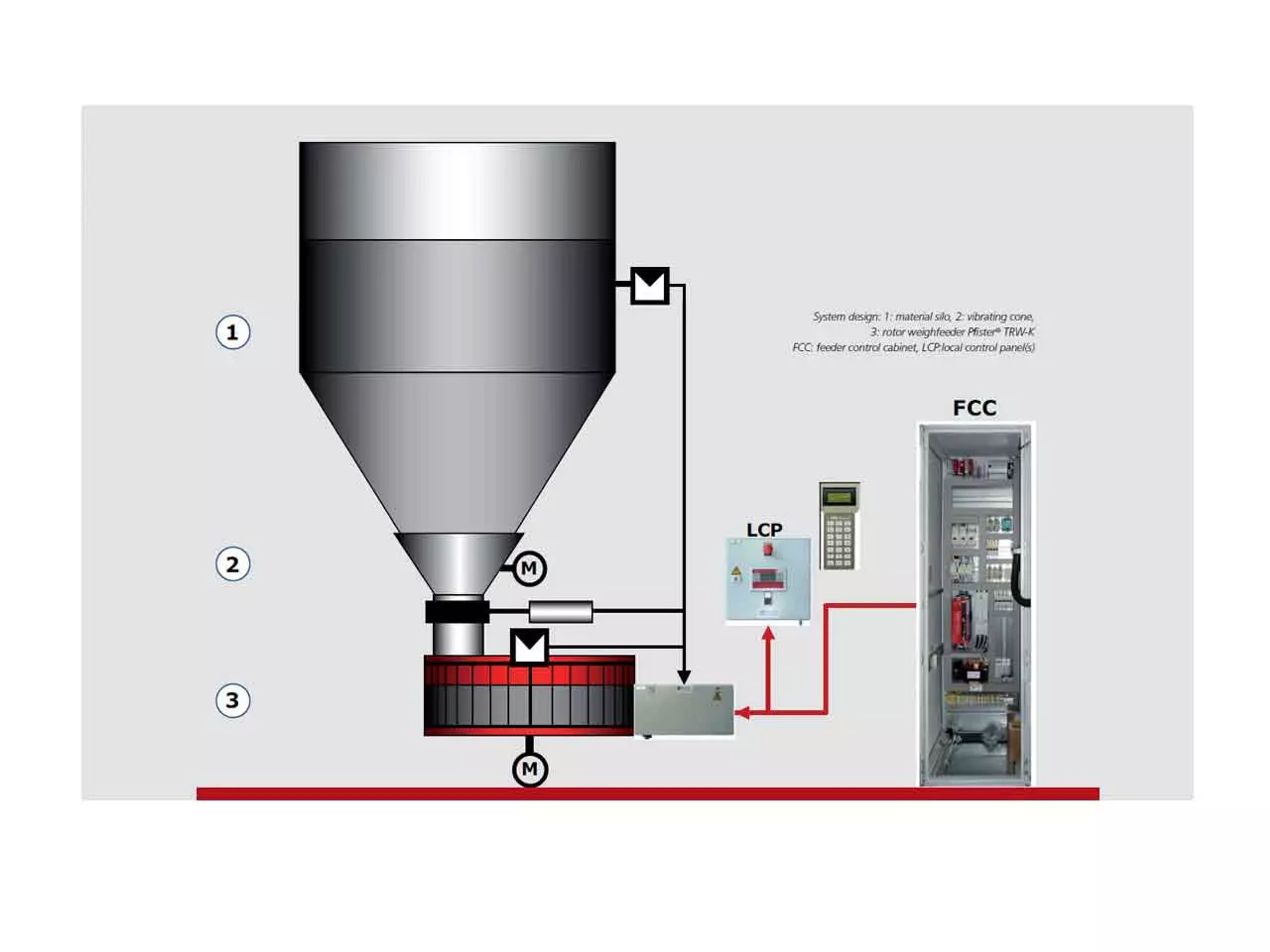

All our rotor weighfeeders are based on the same weighing and dosing principle. The picture below illustrates the process using a PFISTER® TRW.

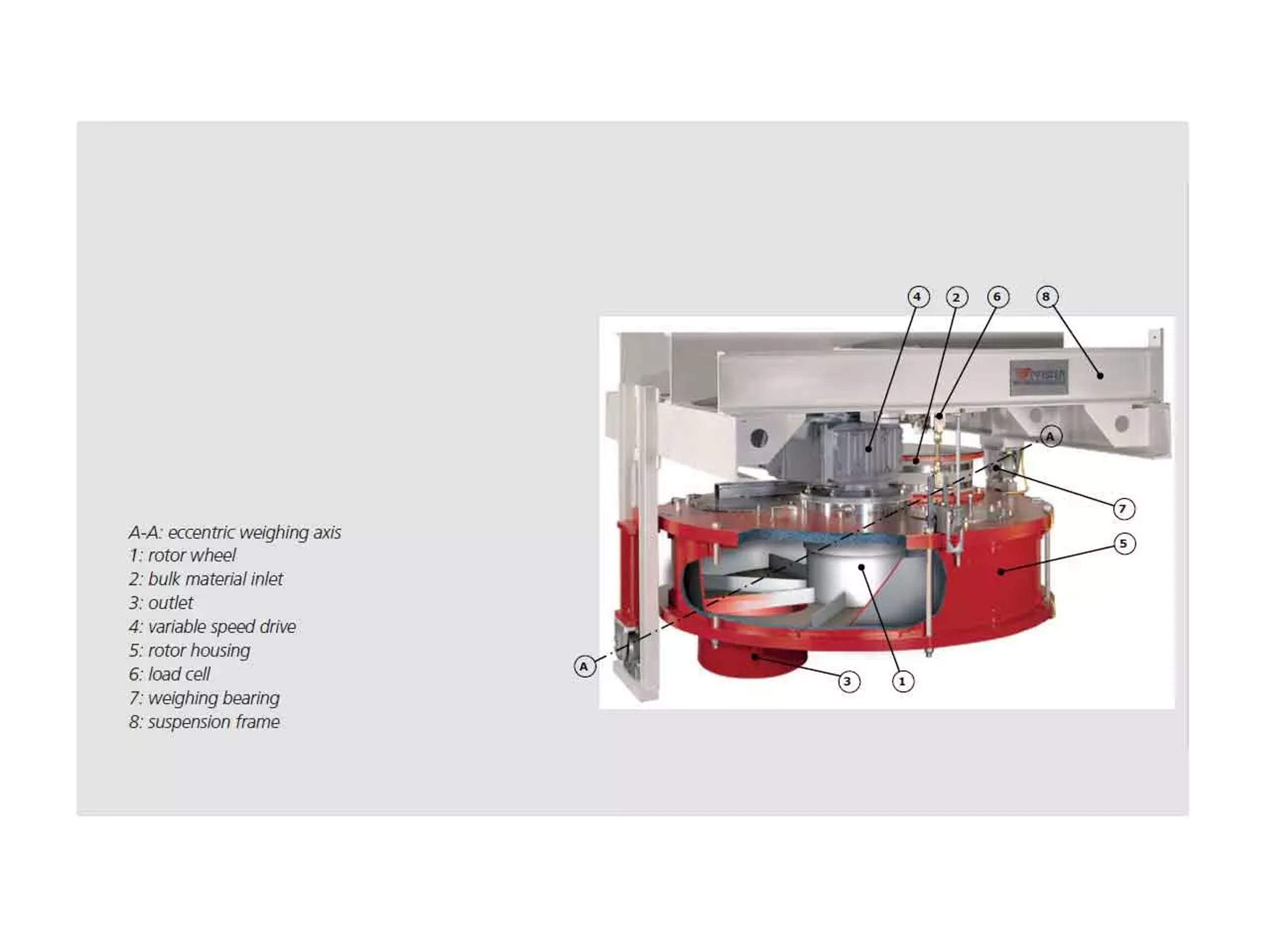

Weighing and dosing principle

Material is extracted out of the material silo and is transported in the rotor chambers (1) from the inlet (2) to the outlet (3). The rotor is mounted on bearings that form a weighing axis (A-A). This axis (A-A) is eccentric to the rotor shaft, and through the middle of the inlet. The third point is suspended at a load cell (6), which weighs the content in the rotor wheel gravimetrically. This means the rotor weighfeeder measures actual kilograms and is therefore a real scale. With the measurement of the gravimetric force, together with the related rotor wheel position is stored by the advanced weighing electronics (ProsCon®) and used to calculate the required rotor wheel speed. The greater the load, the slower the rotation and vice versa. The feeder then discharges the material at the outlet (3) with a highly accurate mass stream.

In control, always

ProsCon® enables precise and proactive control of a system where the feed material tends to be variable. Differences in material density and size, which may impact the accuracy of a volumetric feeder, don’t affect the precision of a smart gravimetric feeder that doses based on weight and reacts almost instantly to changes in the make-up of the feed. The rotor weighfeeder control system is called F-Control™. It includes a control cabinet (FCC), which is located in the plant’s motor control centre (MCC), as well as local control panels (LCP) specifically designed for the environment surrounding the rotor weighfeeder (FIELD). The FCC contains all controller parts for dosing and regulation of the rotor speed, and also monitors these functions. The LCP contain the interface to link the F-Control™ dosing control to the process and all devices to provide local access for maintenance and service operation.