Lift your productivity with our process control technologies

We’ve been supporting the cement industry for nearly 150 years. This has provided us with a unique awareness of current market needs and an unmatched understanding of plant processes.

An efficient operation is a successful one. We’ve always worked closely with our customers and we understand the challenges you are facing today: the competitive global environment, rising energy costs, tighter emissions and high staff costs. To survive, and indeed thrive, you need to keep costs low while lifting your performance.

That’s where we can help. We offer a wide range of process control and optimisation technologies to improve virtually every aspect of your operation. We can help you lift throughout/output, cut energy costs, reduce downtime and much more.

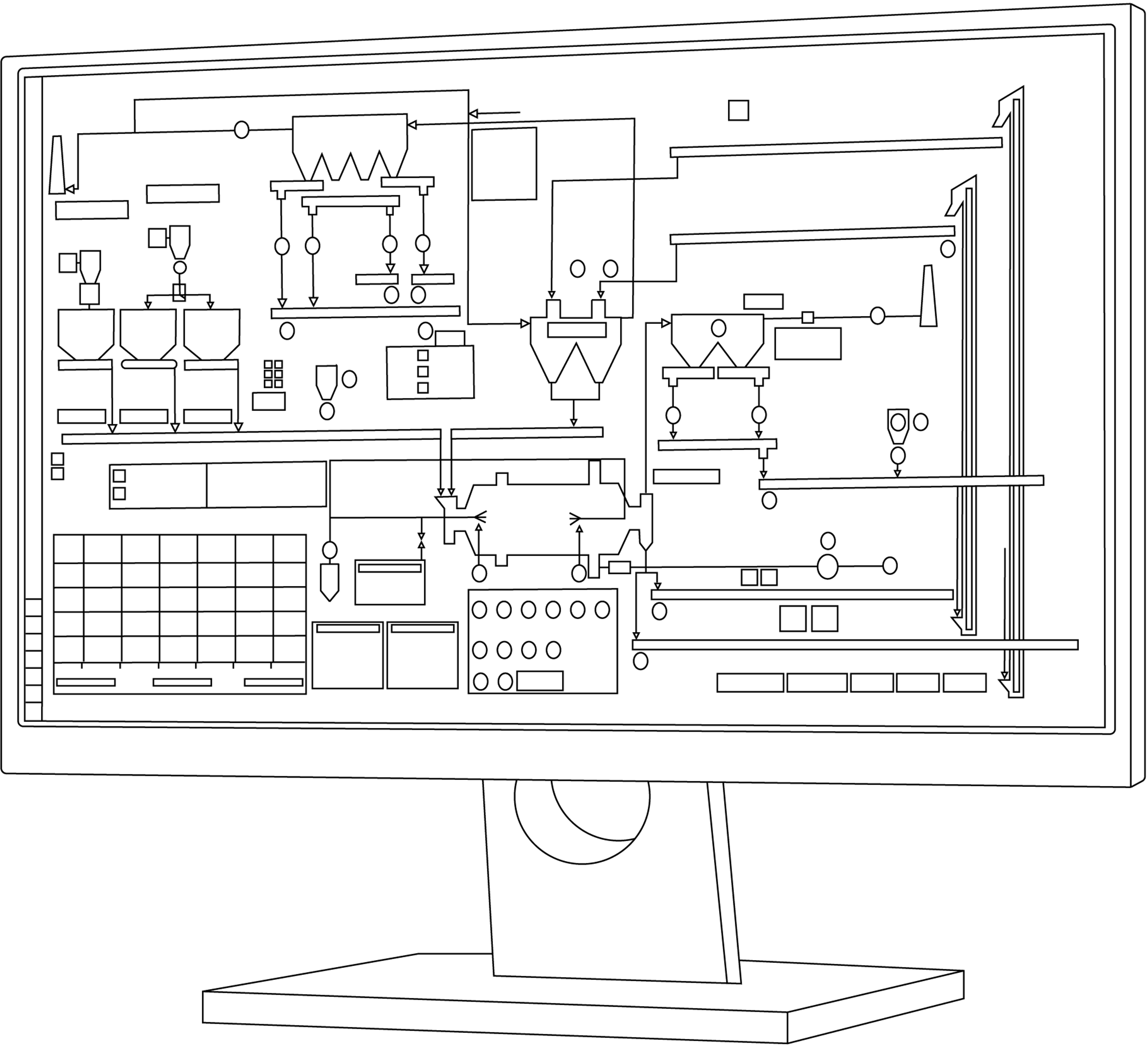

Superior automation

When you embark on the digital journey you want a partner that provides the complete range of automation and integration products, solutions and services. With the help of our ECS process control solutions and the expert knowledge of our engineers and support staff, we deliver real digital effectiveness to your plant and equipment. By automating your processes you’ll be able to ensure your plant is always working at its full potential while alleviating the risks of process instability and inconsistent quality. That means a stronger performance with less downtime and lower maintenance costs.

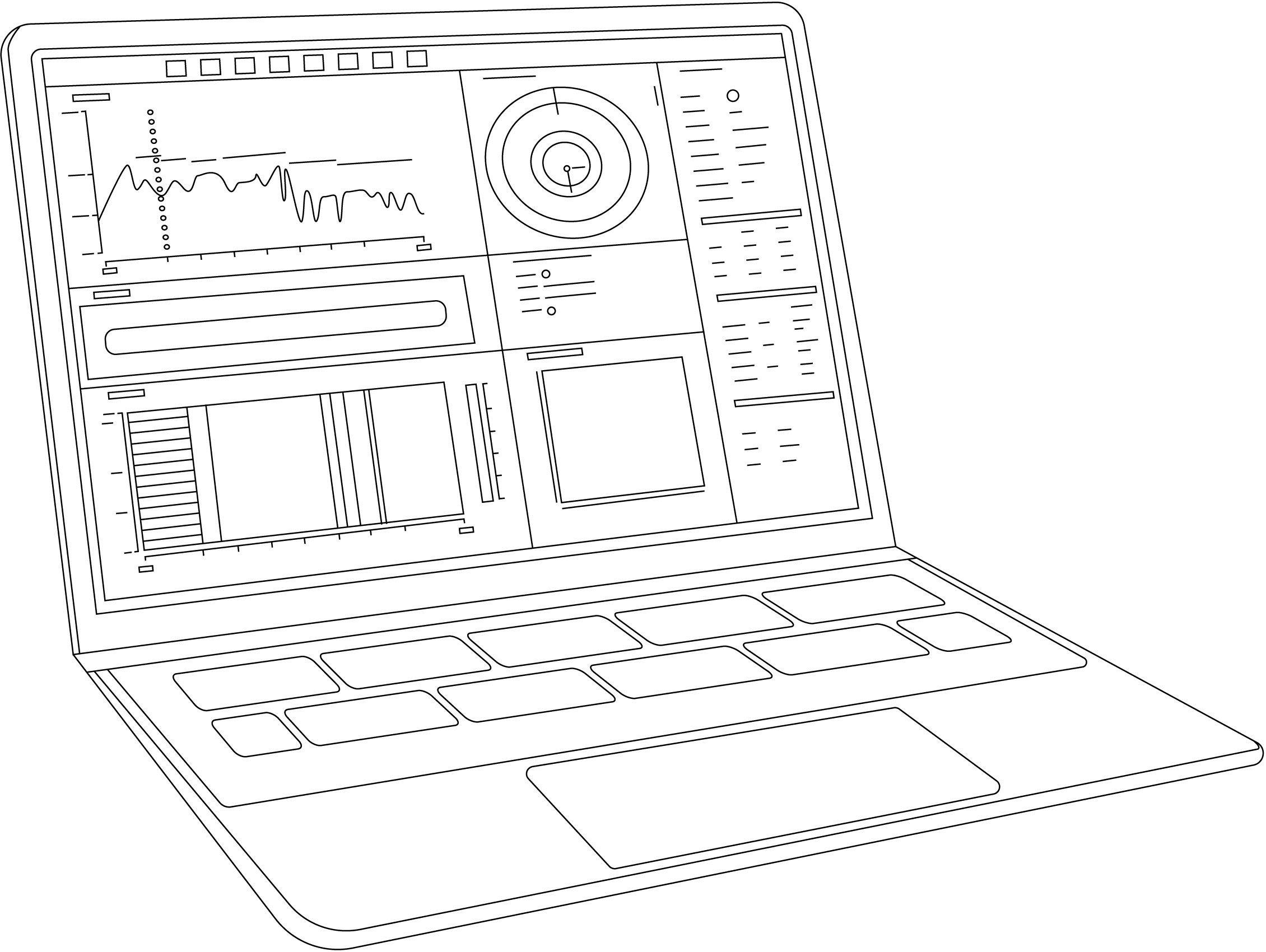

Monitoring and analysis

The first step to improving the performance of your plant is understanding exactly what is going on inside it. Of course, that’s easier said than done when you are dealing with extremely harsh and sometimes unpredictable conditions. But the good news is we offer a range of technological solutions that can assist. These will allow you to closely monitor conditions inside your kiln or mill, track energy usage, and much more. Once your operators know exactly what is going on inside your plant and how your equipment is performing, they, or their plant managers, will be able to make better decisions to ensure peak performance in maintained.

Digitalisation

Digital goes beyond just adopting separate pieces of technology though — it needs to be key to solving the business issue of improving productivity and margins across your value chain. We provide a number of technologies that are at the forefront of this trend. Greater digitisation will help drive greater productivity in your operations by reducing operating costs and stabilising your processes and product quality. It also increases the scope for remote control of plant and equipment.

That also results in better process safety through earlier identification of problems. Your operators will become more effective as they only focus on key parameters. And you will gain increased process understanding as clear, real-time information is available at your fingertips.

Energy and emissions

One of the biggest challenges for any operation is managing energy usage. High power or fuel bills can sap your profitability and there is ever-present pressure to rein in emissions. We offer a number of solutions that can help you monitor and reduce energy usage by ensuring your plant and equipment are operating as efficiently as possible. You will also have the tools to see exactly where your energy is being consumed within the entire process.

The FLSmidth Cement difference

When you choose us you get more than just a product. Everything we do is backed by our expert teams of process engineers, project managers and support staff. We’ve got a proven track record of delivering on time and can upgrade your equipment and systems with little to no downtime to avoid production losses. Once our solution is installed, you’ll also have access to round the clock support and troubleshooting from our team, so you can be confident we’ll always be there to help.

_Kiln_Shell_Monitoring_System.png?w=3840&q=80&auto=format)