Hot kiln alignment: a pillar of your preventive maintenance strategy

What we offer

Comprehensive kiln analysis with hot kiln alignment services

To keep your kiln operating at maximum efficiency throughout its entire service life, you need in-depth, accurate knowledge about its condition. A hot kiln alignment helps identify potential causes of failure before problems occur, giving you the information you need to avoid any unforeseen breakdowns. The better your maintenance programme, the greater your kiln availability. A comprehensive hot kiln alignment involves a visual mechanical inspection, including geometric and dynamic measurements. It also includes an engineering study, where we calculate stresses in the kiln and determine if there is overload, taking into account all the current operating conditions and the measured kiln axis. Everything is done during normal kiln operation, allowing you to continue production, uninterrupted.

Identify root causes of issues

Some plants find themselves continually treating symptoms, unable to get on top of the real issues. This leaves room for the root cause of the problem to escalate, causing untold damage and even unplanned outages. A hot kiln alignment, as part of a preventive maintenance approach, allows you to identify the root of the problem, so you can stop wasting time and resources fighting fires, and get back to optimum productivity.

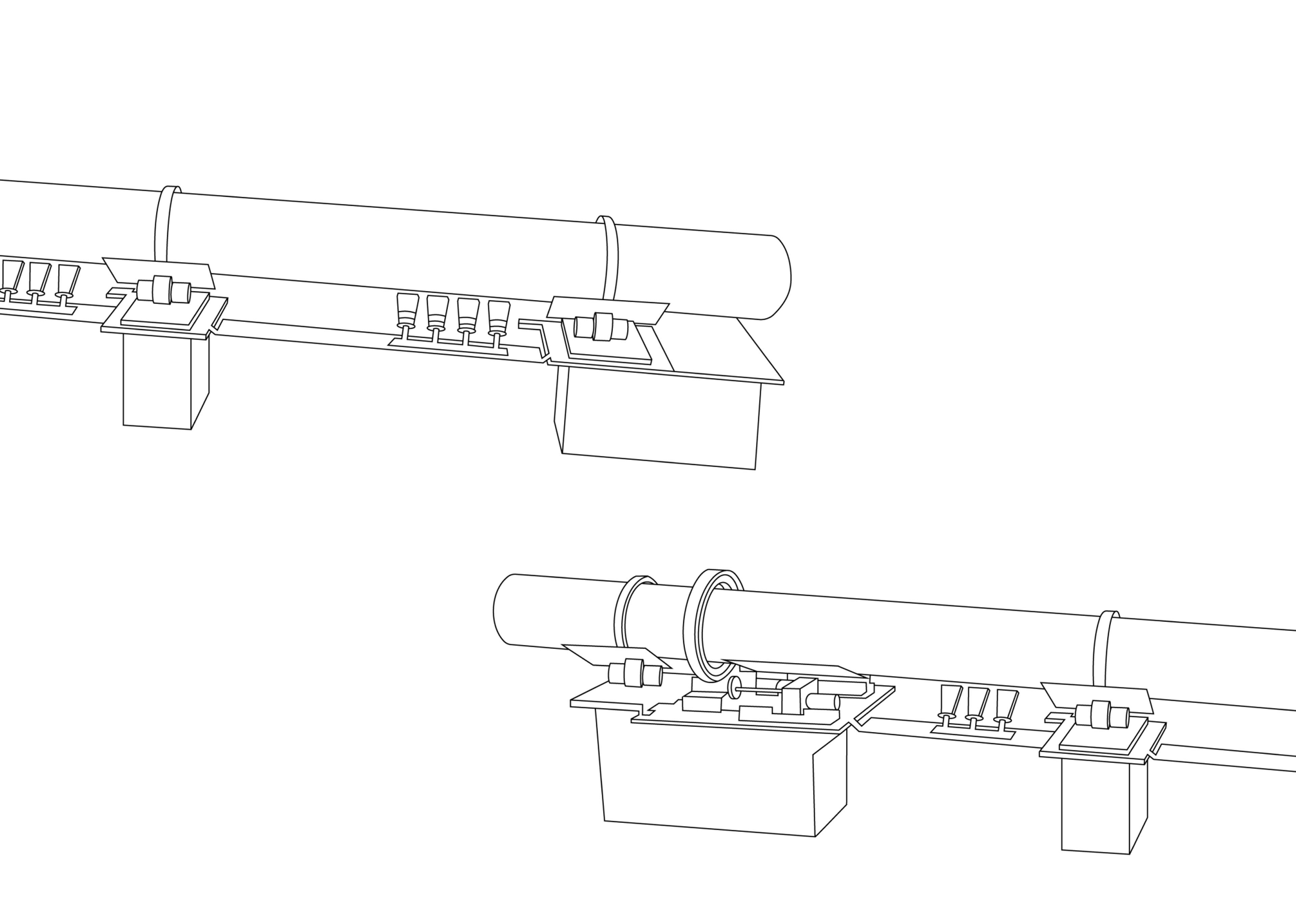

Our comprehensive hot kiln alignment focuses on four areas that are typically at the root of kiln problems:

- Kiln axis

- Kiln shell ovality

- Axial balance

- Kiln crank

Easy to understand visual diagnosis

Using state-of-the-art software, we create detailed, interactive 3D models of your kiln shell, letting you easily see any areas of deformation or weak spots. Different colours allow you to visualise kiln shell deformations and the varying degrees of severity, giving you a clear diagnosis of the state of your kiln shell. These insights are vital in identifying issues related to lining failure or kiln crank. We include these interactive models in your final report, helping you to effectively plan your preventive maintenance.

Improving availability adds value

An unexpected kiln stop is very costly. Typically, a comprehensive kiln alignment investment is paid back simply by avoiding one unplanned stoppage. In addition, by having a better understanding of your kiln condition, you can improve your spare-parts planning. A kiln alignment will help identify the parts you should keep in stock, reducing your material asset budget.

Create a maintenance schedule with minimum downtime

Armed with all this information, you have the knowledge you need to plan your next maintenance shutdown to minimise costs and duration – a distinct benefit.

As the final key part of your kiln alignment, we’ll present a comprehensive report containing all our findings, measurements, conclusions and recommendations, including short-term and long-term solutions for improvements.

Expert insight from an OEM

As an OEM with decades of experience and thousands of references worldwide, we bring an added element to all our comprehensive hot kiln alignments: unrivalled expertise. We channel all this experience and knowhow into the kiln engineering study, which combines the results of our work on-site with engineering load analyses to determine if the kiln is overloaded. We call it a behind-the-scenes-study as it can reveal overload, highly stressed items and allow for you to take action before issues arise. Again, these insights are invaluable to getting the most from your kiln – and to planning for the future.