Pneumatic transport excellence

Our engineers and specialists have several centuries of combined experience in pneumatic conveying. We work closely with customers and partners to continuously seek broader applications for our products, processes and technologies. This enables us to meet the ever-increasing demands of evolving and diverse industries. From efficient and low-maintenance pipeline conveying, to our low-power fluidisation systems and gravity conveyors, our wide range of products and solutions consistently meets the specialized needs of our customers, worldwide.

Efficient technologies and solutions for terminals

Whether you receive and distribute material by ship, barge, rail, or truck, we have pneumatic systems designed to make your terminal operate efficiently and reliably: Docksider™ and KOVAKO® high-capacity ship and barge unloaders Airslide® gravity conveyors and Ful-Floor™ fluidized reclaim systems Fuller-Kinyon® Pumps, Ful-Vane™ compressors and related products The technology and commitment to product development and testing have made us the leading supplier of storage silo fluidization and withdrawal. We engineer all our storage silos to maximize the benefits of fluidization while minimizing power consumption.

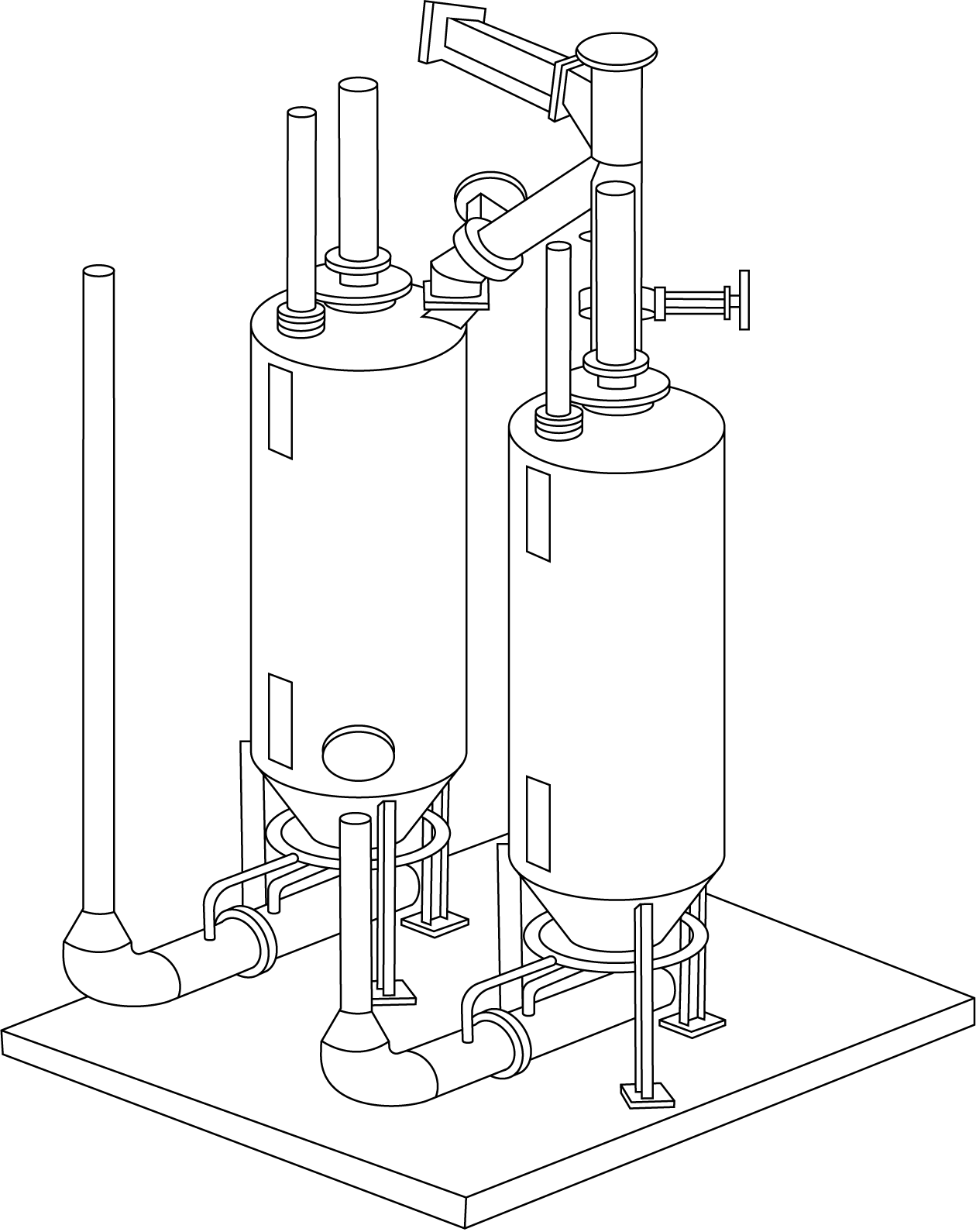

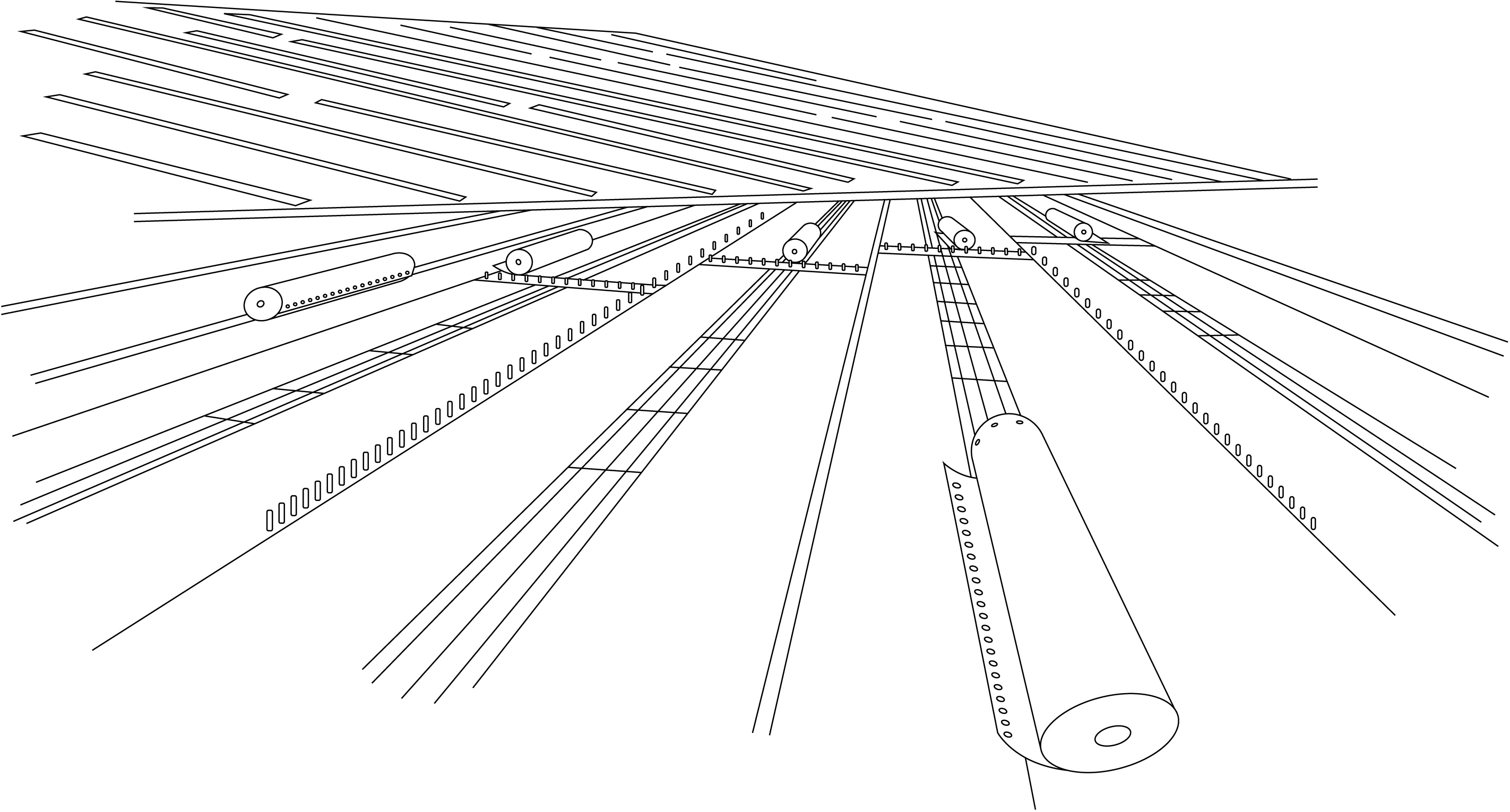

Ful-Floor™ pneumatic reclaim system

Our Ful-Floor™ reclaim systems use our industry-proven Airslide® fabric anchored to nearly 100% of the floor area. Embedded aeration troughs and piping eliminate restrictions that can inhibit material flow. The results: complete reclaim of your stored material with minimal floor slope, low average power and low maintenance. Reclaim from storage is just one part of terminal system management solutions. We can design and supply your complete control system to distribute the material flow, monitor inventory and transfer between storage facilities or directly to trucks, railcars, barges or ships.

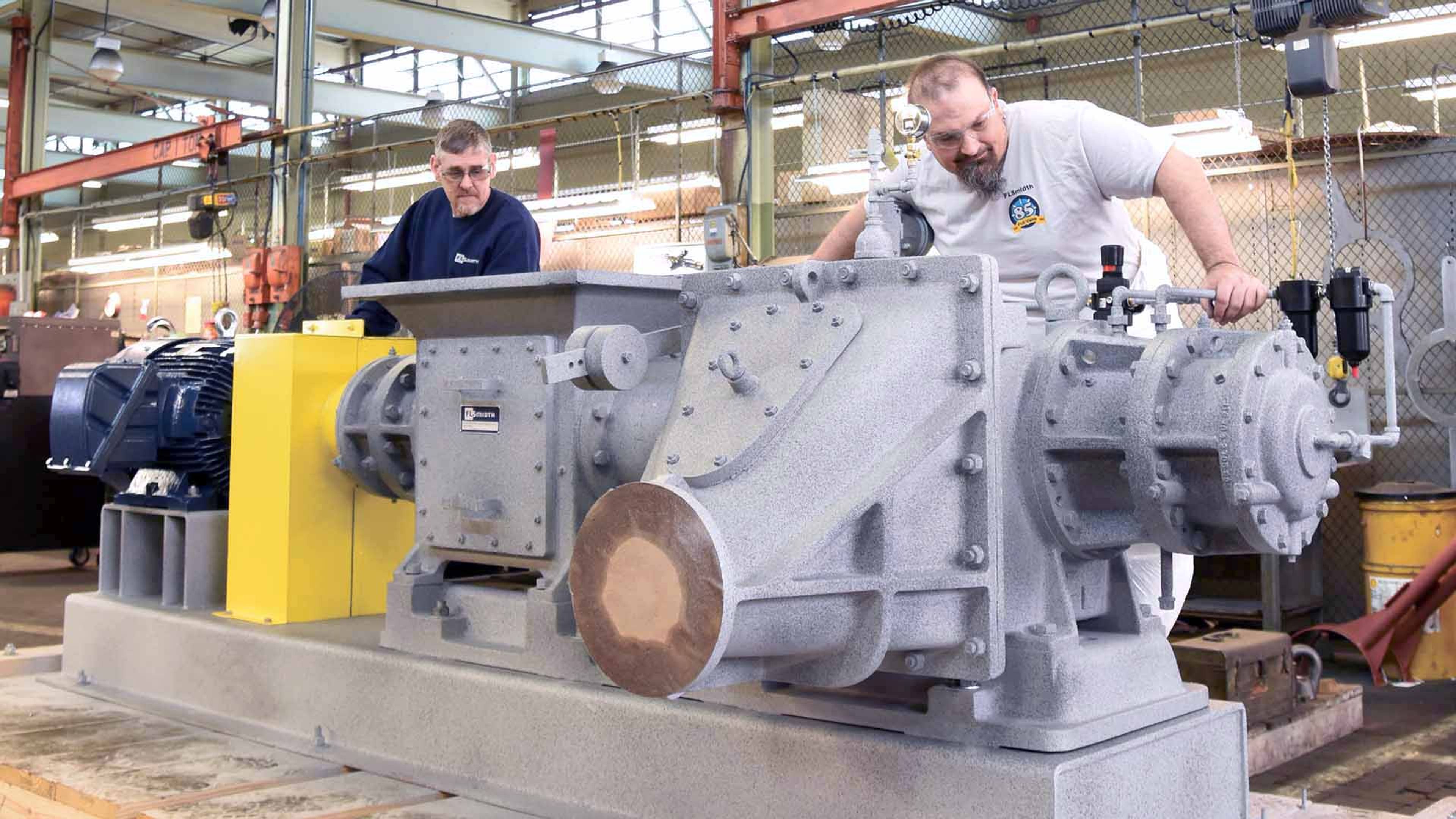

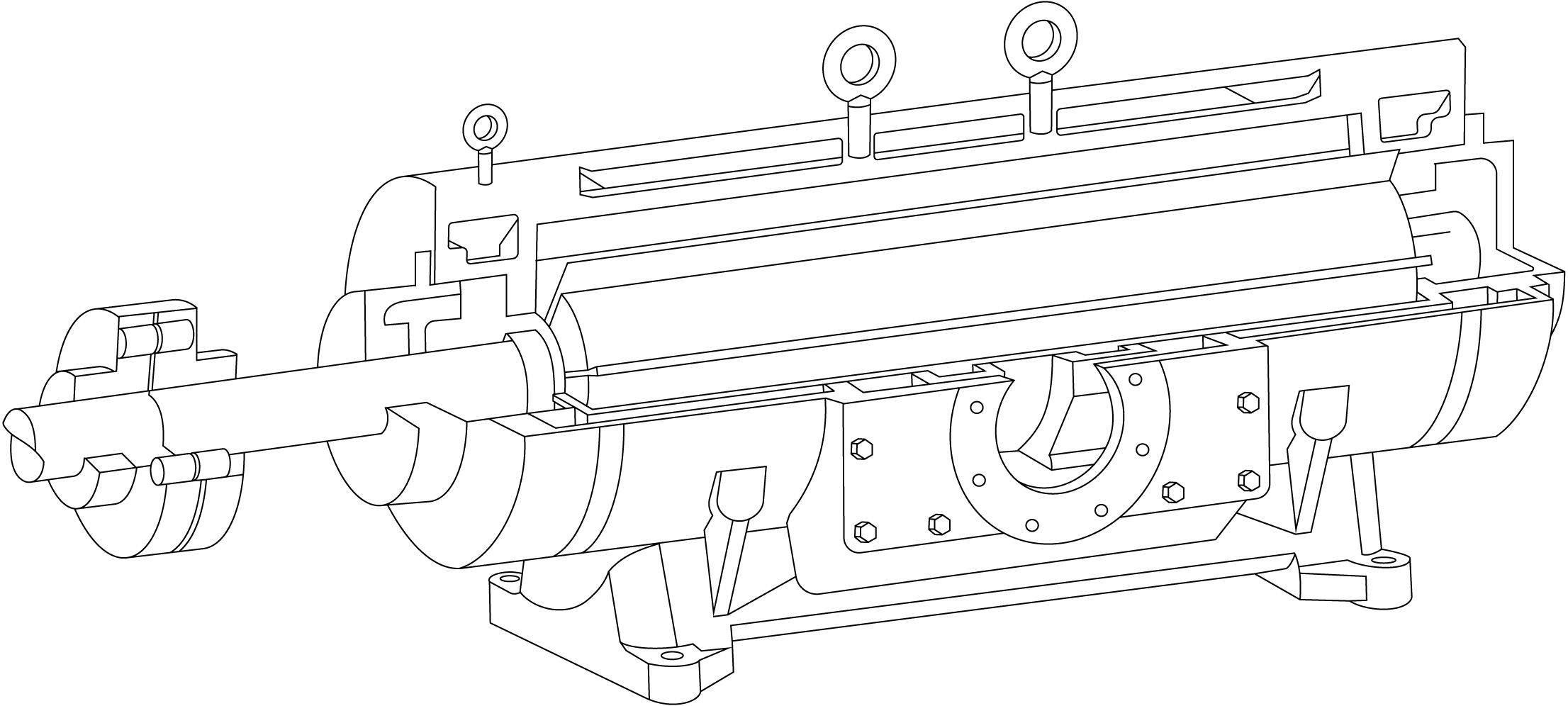

Fuller-Kinyon® pump

An industry standard, the original heavy-duty, screw-type pneumatic Fuller-Kinyon® pump began a long line of innovative products engineered for proven reliability and dependable performance. Pump systems using Fuller-Kinyon pumps are most commonly used to convey dry, free-flowing, pulverized materials from grinding mills, transfer materials from silo to silo, transfer dust from collectors, and load and unload railcars, ships and barges.

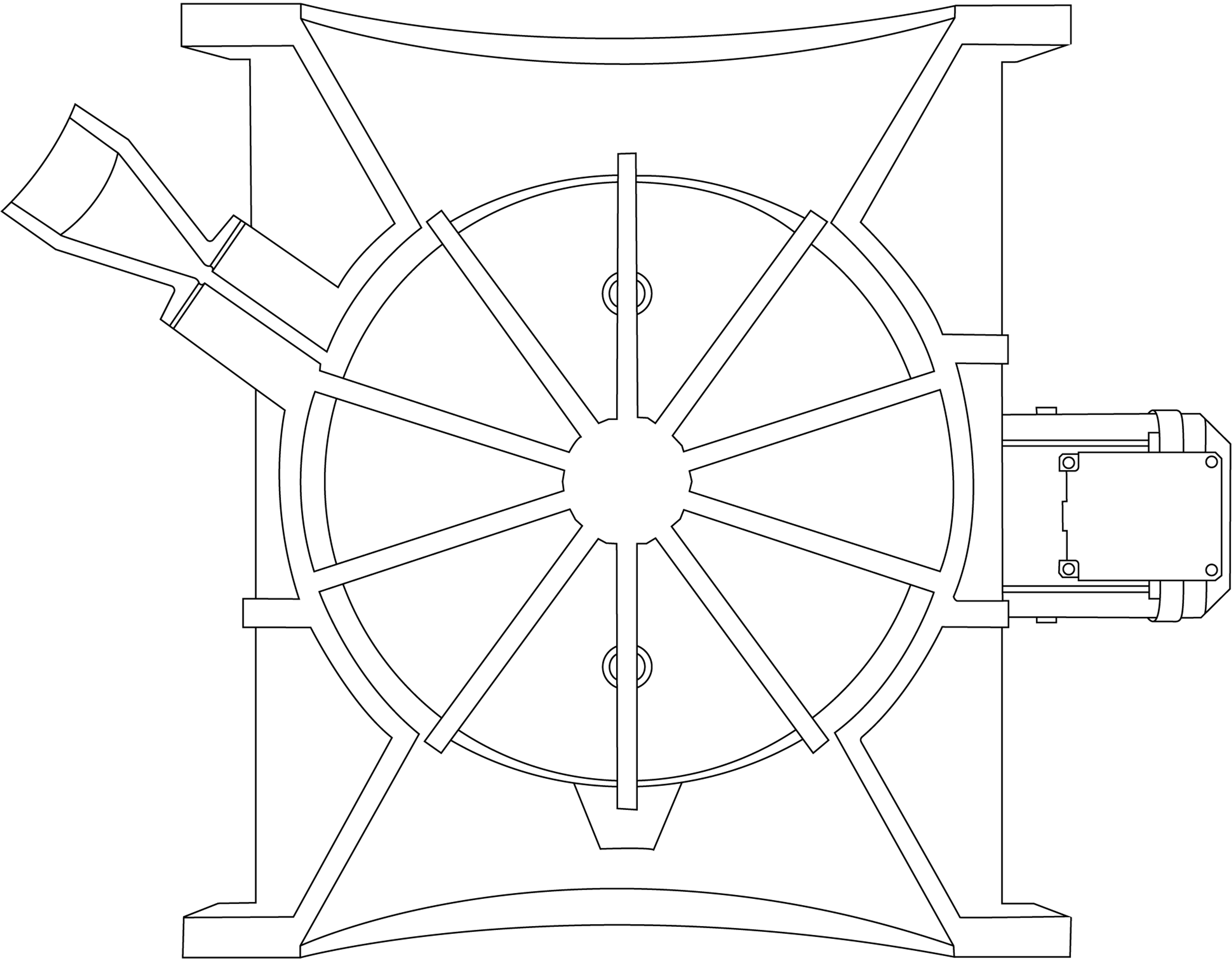

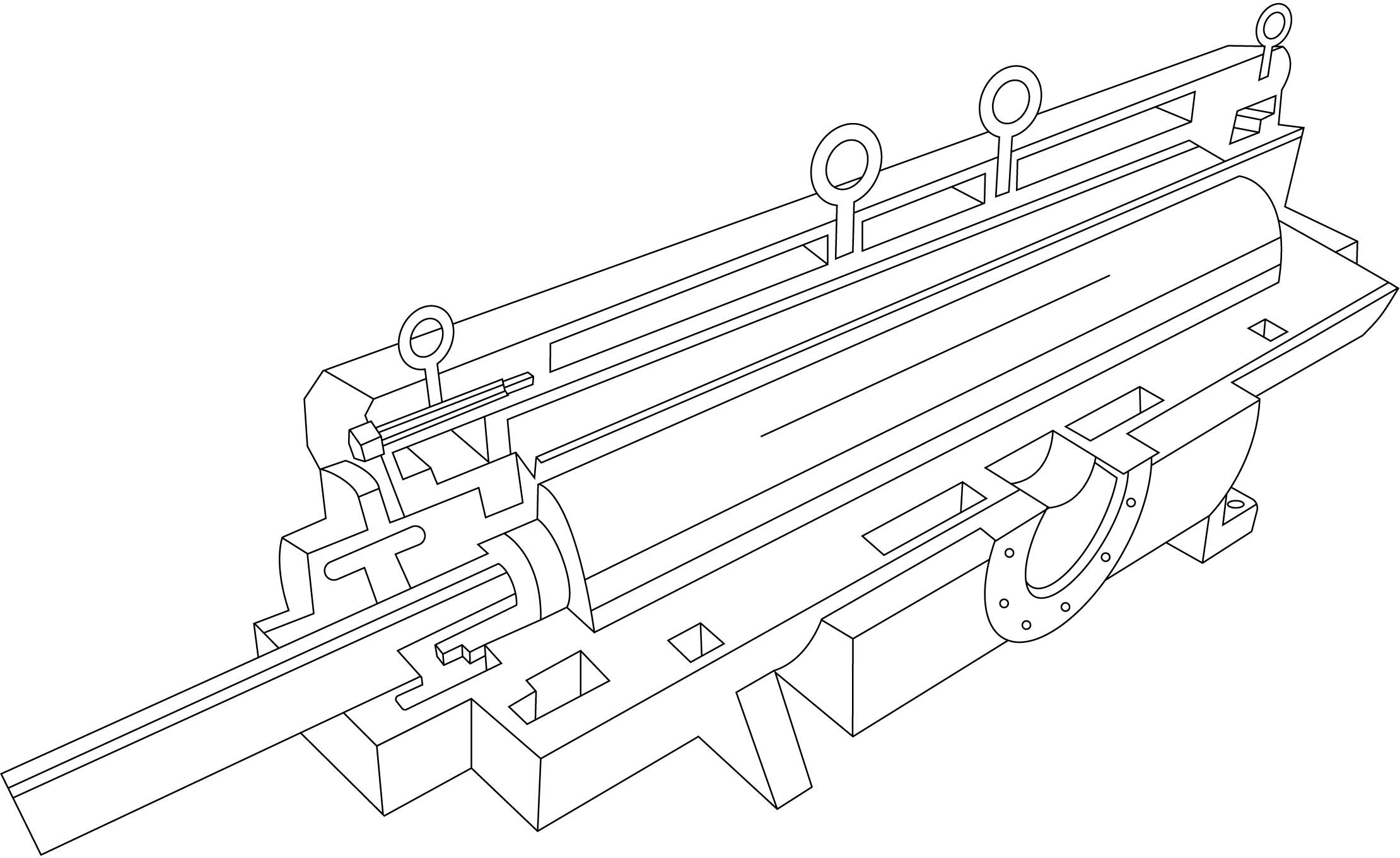

The original Airslide® conveyor

Our Airslide® air-gravity conveying system uses the forces of gravity to do most of the work with no moving parts. Material is fluidised through a porous media with low-pressure air, and flow is achieved by sloping the Airslide conveyor to match the fluidised angle of repose of the powdered material. These air-gravity systems provide high-capacity material handling while offering many economic and environmental advantages. Benefits include low energy requirements, and since the system is installed overhead, valuable floor space and added headroom are available for other purposes.

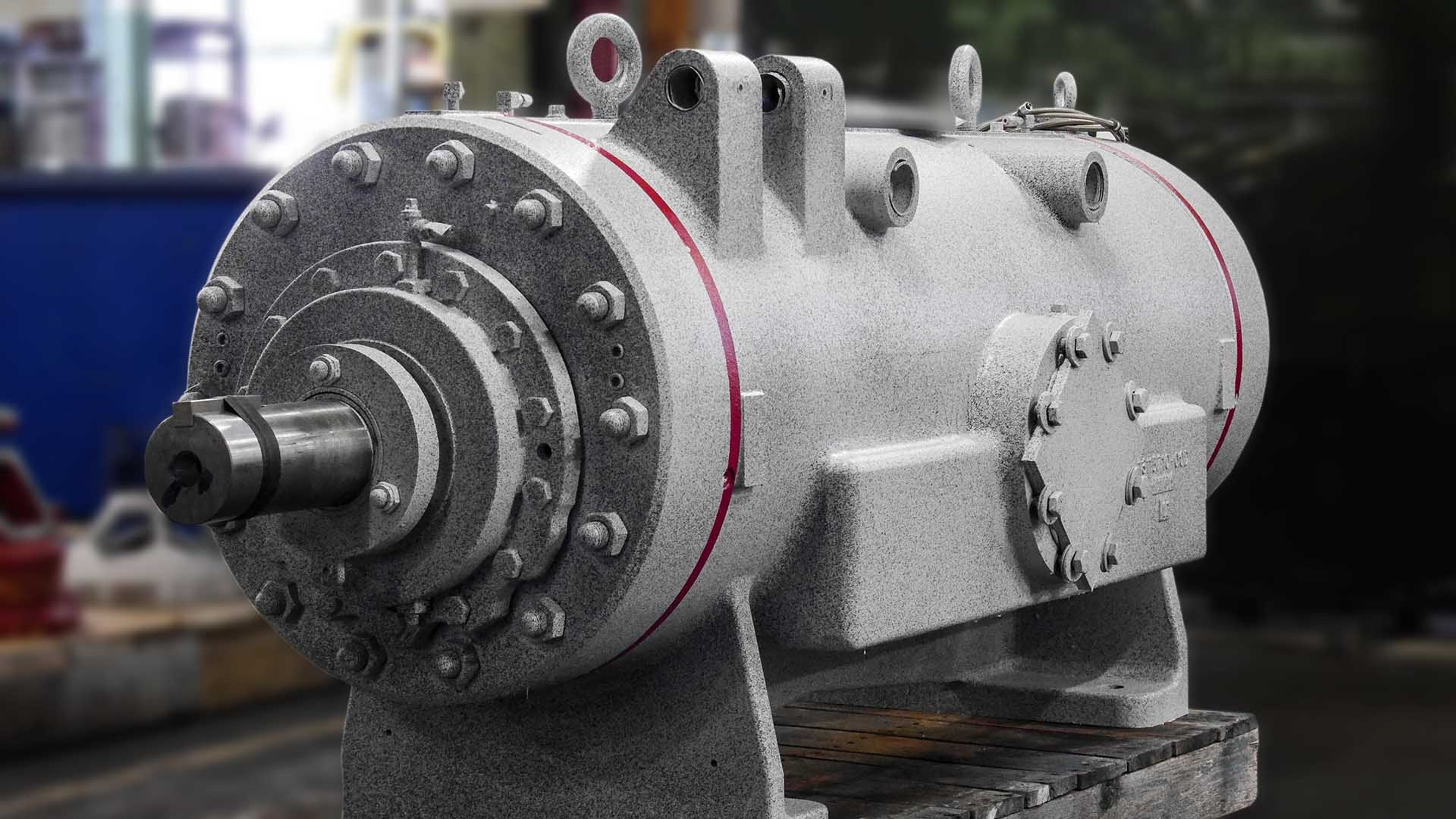

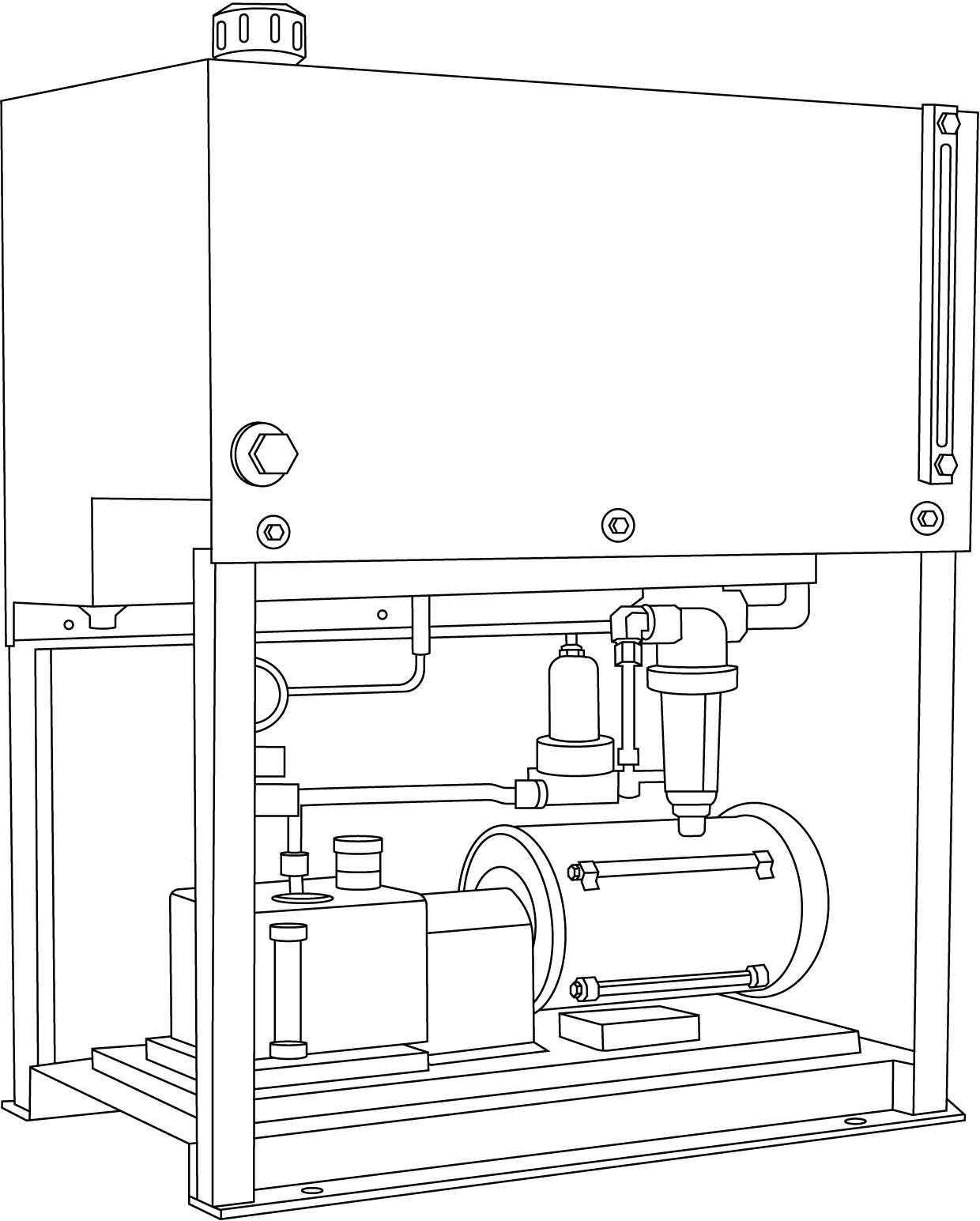

Ful-Vane™ compressors

Developed from Fuller® design and technology, our Ful-Vane™ Compressors provide more compression with less energy. Our unique design features include large air flows, low mechanical and drive losses, and high compression efficiency. With only two bearings and three moving parts, the Ful-Vane compressor boasts a simple design that is easily field repairable. As a result of minimal internal and mechanical losses, Ful-Vane compressors have higher operating efficiencies. Since the vanes compensate for wear, the compressor maintains its design efficiency over time.

Pneumatic blending silos

Our pneumatic blending silos are engineered to maximize the benefits of fluidization and gravity technologies over mechanical blending. This technology gives you operating efficiency, low power consumption, flexibility and increased productivity. Our product range can combine storage and blending for space-saving plant layouts.

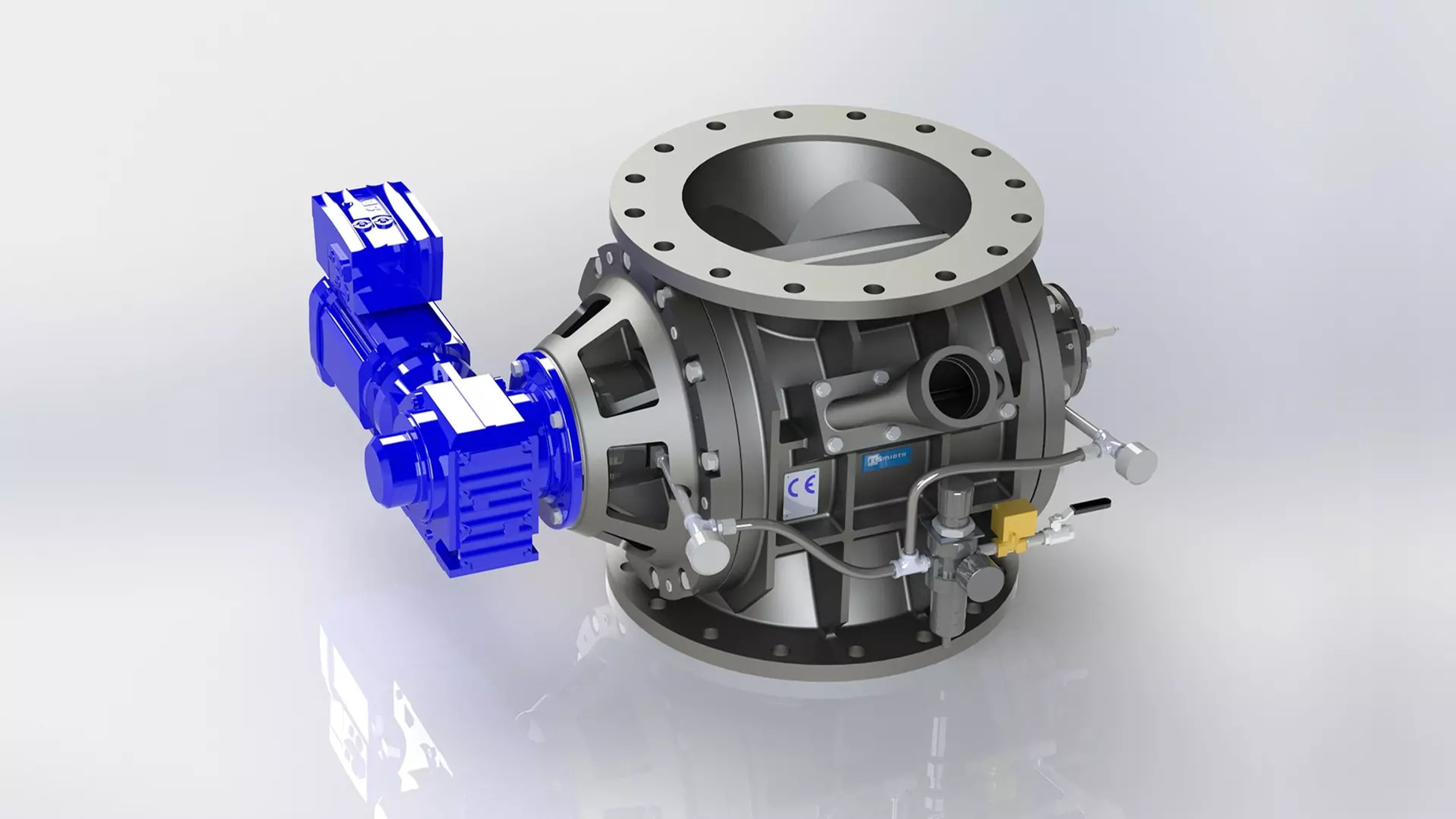

Rugged components for tough applications

Our heavy-duty feeders, airlocks and valves are field-proven in countless applications. They help maximize the performance of both pressure and vacuum pneumatic systems. Standard feeders and airlocks such as our V-Series feeder are constructed of cast iron, or a combination of iron and steel, and are also available in special combinations of stainless steel, aluminum and/or ductile iron. Feeders and airlocks are available with a special abrasion-resistant ceramic lining for long operating life, reducing downtime and requiring minimal maintenance.

SK V2 diverter valves

Our heavy-duty quality diverter valves are widely used in pneumatic conveying and related industries, including specialized equipment for the chemical, coal, power, mining, pulp and paper, petroleum, and metals processing industries. We provide a valve solution for virtually every application.

Support and service

Our Customer Service group is committed to improving the productivity of your plant. We do this through world-class services and equipment programs, by providing sound productivity-enhancing solutions, and clear person-to-person communication. We offer several programs to support and enhance your process, reducing equipment downtime and cost of operation. We provide the equipment and expertise to help keep your project running smoothly, safely and efficiently, making sure your plant operates at the lowest total cost of ownership and is set up to deliver the highest level of productivity. Our equipment exchange programs, on-site training, parts stocking programs and mini-audits are all part of our dedication to our customer’s productivity.

Research and development

Our R&D team is dedicated solely to the advancement of pneumatic technology. Test configurations are designed and equipped to simulate even the harshest field conditions in a precisely controlled laboratory environment. Both optimal and worst-case scenarios can be identified and designed for, resulting in the highest levels of performance, quality and reliability.

_vertical_conveying.png?w=3840&q=80&auto=format)

_Rotary_Vane_Gas_Compressor.png?w=3840&q=80&auto=format)

_Rotary_Vane_Air_Compressor.png?w=3840&q=80&auto=format)

_lubrication_systems.png?w=3840&q=80&auto=format)

_Pneumatic_Reclaim_System.png?w=3840&q=80&auto=format)