Our EV Hammer Impact Crusher maximises crushing of large feed blocks

What we offer

Our highly-effective EV Hammer Impact Crusher offers prime crushing

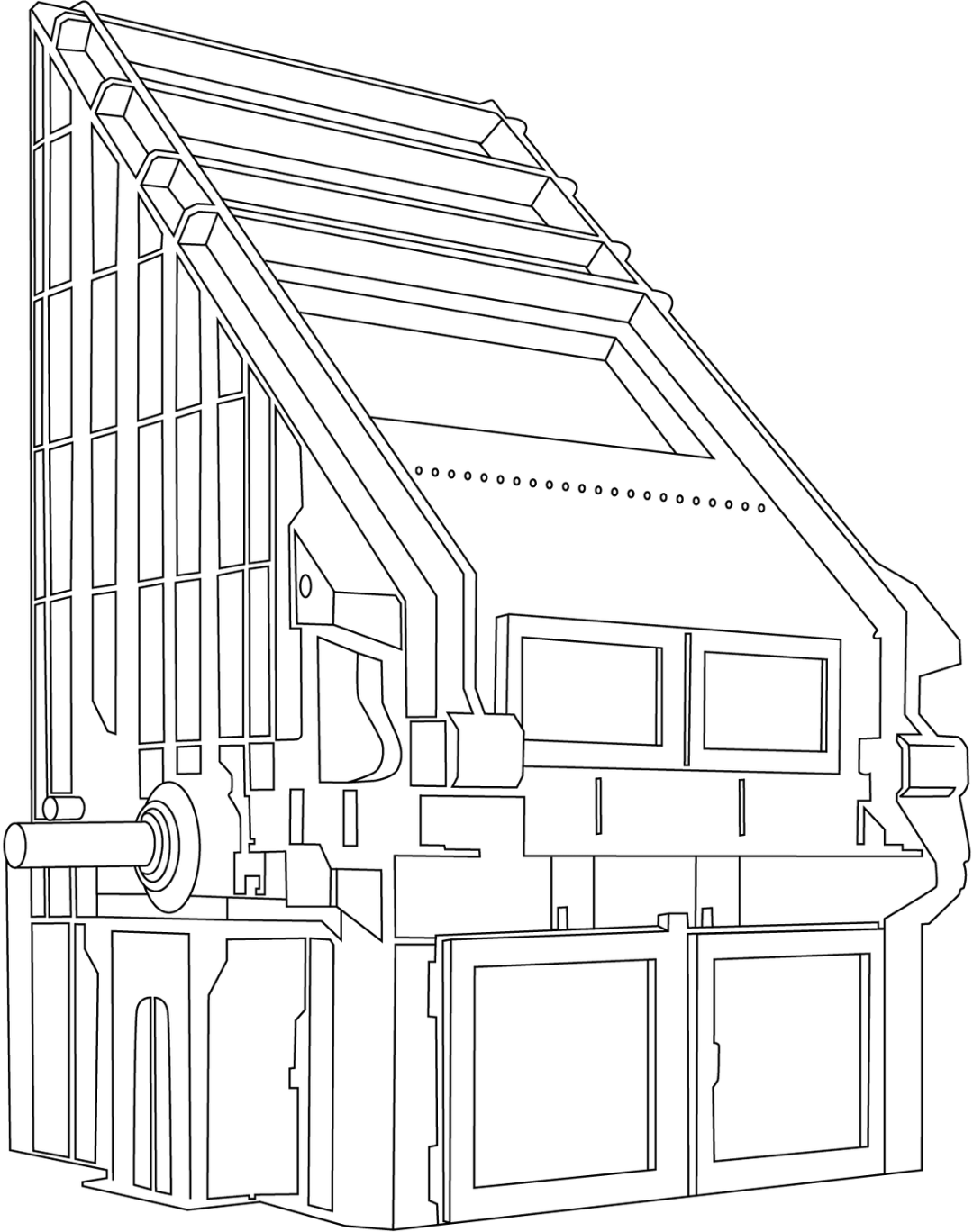

Many cement plants extract limestone by blasting, which often leads to oversized boulders containing a lot of clay and sand. The crusher therefore has to handle feed that contains larger blocks as well as some sticky materials. Our EV Hammer Impact Crusher is a proven, reliable and cost-effective impact crusher that help to overcome these crushing challenges.

Combatting large feed block challenges

In traditional hammer crushers with a top inlet, introducing large blocks in the feed can impede the action of the hammers and block the crusher. Our EV Hammer Impact Crusher, however, competently reduces quarry-size limestone boulders measuring up to 2.5 metres and weighing up to 5 tonnes to mill feed of 25 millimetres. This is a reduction ratio of 1:100 in a single operation.

The EV Hammer Impact Crusher features a highly effective two-stage crushing process. Primary crushing takes place by impacting. Secondary crushing takes place by shearing and compression between the impact hammers and the breaker plate and between the hammers and the outlet grate. This ensures that even the smallest particles absorb energy and that no oversized particles leave the hammer impact crusher. The horizontal feed system can also tolerate coarse feed blocks because of its shock-absorbing inlet rollers.

The EV Hammer Impact Crusher’s throughput capacities range up to 2200 tonnes per hour (tph) with an outlet grate and 2500 tph without an outlet grate. Motor sizes are typically in the range of 500 - 2500 kW.

Hammers take centre stage

The hammer rows, which can vary depending on your crushing capacity needs, are arranged to provide complete coverage across the outlet grate. By arranging them in this way, the raw material can be crushed at multiple points increasing overall efficiency.

The symmetrically-shaped hammers are free to pivot around the bolts, reducing the impact from the contact between material and hammers, thereby protecting the rotor and crusher housing.

Adjustment of the spacing between the hammers, breaker plate and outlet grate can be optimised to compensate for hammer wear. Even when the hammers lose up to 30 percent of their original weight, the required product size curve is unaffected.

Grate expectations

The adjustable outlet grate gives the EV Hammer Impact Crusher control of the maximum size of the product. The grate ensures a consistent flow to the conveyor and protects it against any sudden impact of material leaving the impact crusher at high speed. The grate also protects other nearby machinery from being damaged during operation.

The hold-up mechanism of the outlet grate generates a crushed product with a relatively high proportion of fines. In this way, more of the comminution work is moved from the less energy-efficient raw mill to the more energy-efficient hammer impact crusher.

Tough and long-lasting Hammer Impact Crusher with two-stage crushing

Reduces rocks to mill feed in one operation

A smart two-stage crushing process sees the feed material being crushed in one reliable operation. Impacting occurs before the feed is sheared and compressed between the hammers and breaker plates, and the hammers and the outlet grate.

Lower civil costs

The crushing solution has been designed to have a simplified plant layout that encompasses a low installation height. This compact design results in a smaller footprint, saving you civil construction costs.

Easy to maintain

The top part of the hammer impact crusher can be easily opened, providing access to the EV Hammer Impact Crusher. We provide you with hydraulically-operated tools for fitting and dismantling the heavy hammer bolts. These tools together with the hammer handling rack make hammer rotor maintenance safer and much more efficient, minimising production downtime.

Long-life wear parts

All exposed surfaces in the hammer impact crusher, including the adjustable breaker plates, are lined with durable bolted-on, wear-resistant plates. Other design elements help to absorb shock, and prevent distortions and formation of cracks.

Overcome your crushing challenges with our EV Hammer Impact Crusher

Staggered hammer arrangement increases efficiency

The hammer rows are fitted in a staggered configuration to give complete coverage across the outlet grate. This provides several points for crushing of the raw materials, increasing the overall efficiency of the crusher. The hammers are pivotally suspended from bolts and are symmetrically shaped. This reduces the full brunt from the contact between material and hammers, which protects the rotor and crusher housing. The hammers can easily be turned to reverse the leading and tracing edges for maximum service life.

Adjustable outlet grate for control of finished product

Equipped with sturdy, replaceable grate bars supported by heavy cheeks, the adjustable outlet grate allows unique control of the mill feed size using hydraulic systems. This ensures a consistent flow to the conveyor. The outlet grate also serves as protection for the conveyor and other machinery such as reclaimers, sluices and mills, against operational upsets and mechanical damage.

Horizontal feed system smooths operation

A horizontal feed system incorporating one or two shock-absorbing inlet rollers helps to handle coarse feed blocks. The inlet rollers accurately control the feed to the hammer impact crusher and ensure a smooth and even flow of material. Whether one or two inlet rollers are used depends on the method of feeding the crusher.

Durable design features to withstand the toughest material

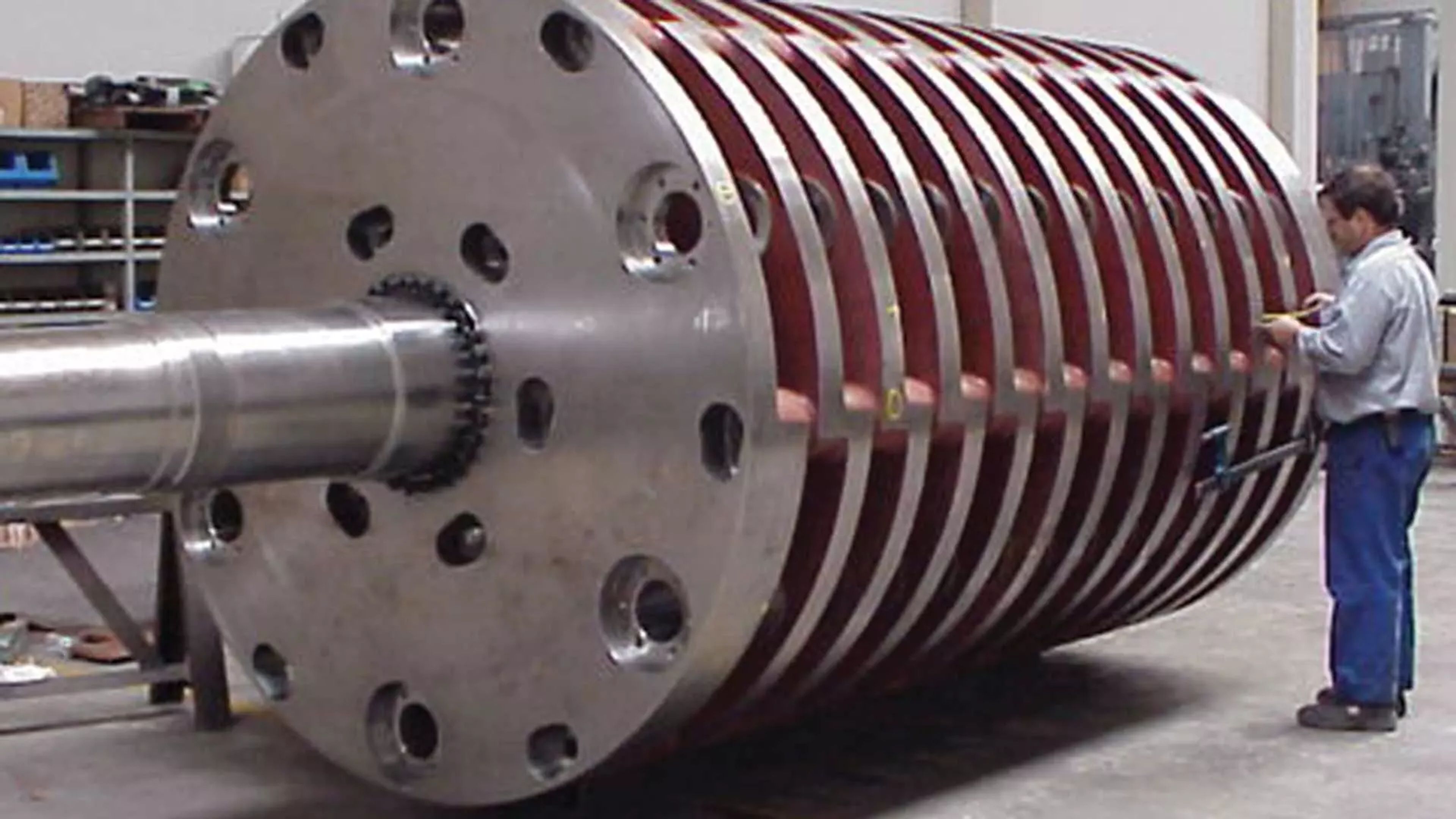

Bolted-on, wear-resistant plates protect all exposed surfaces, including the adjustable breaker plates, from abrasive feed materials. The inlet rollers of the horizontal feed system consist of a cylinder and a concentric shaft driven by a separate motor. Rubber pads inserted between the shaft and the cylinder make the inlet rollers shock absorbent. The hammer rotor assembly consists of a heavy-duty, forged shaft with a square cross section and is also fitted with rotor discs. The unique ´sandwich´ assembly of the discs is a robust construction, that helps prevent distortion and crack formation.

Using hydraulic technology for easier maintenance

The top part of the EV Hammer Impact Crusher can be accessed by means of hydraulic cylinders. The supply package includes hydraulically-operated tools for fitting and dismantling of the heavy hammer bolts. The hydraulic cylinders and tools are served by a mobile hydraulic power unit which can be stored in a separate room when not in use. A lifting yoke facilitates handling of the hammer rows when changing hammers. It also holds them in position when dismantling and fitting hammer bolts.