- Products

Products

- Crushing

- Emission control

- Gas analysis and emissions monitoring

- Milling and grinding

- PFISTER® Feeding and dosing

- Pneumatic conveying

- Process control and optimisation

- Pyroprocessing

- Sampling, preparation and analysis

- Ventomatic® Storage and dispatch

Brochures

Download libraryCrushing

- Impact crushers

Emission control

- Electrostatic precipitation

Gas analysis and emissions monitoring

- Emissions monitoring

- Gas analysis

Milling and grinding

- Ball mills

- Roller presses

- Vertical roller mills

PFISTER® Feeding and dosing

- Alternative fuels storage

- Belt weighfeeders

- Rotor weighfeeders

Pneumatic conveying

- Pneumatic conveying accessories

- Pneumatic conveying feeders and valves

- Pneumatic conveying systems

- Pumps and compressors

- Ship unloaders and terminals

Process control and optimisation

- Process and machine control

- Process data management and insights

- Process measurement and monitoring

- Process optimisation

Pyroprocessing

- Coolers

- Firing Systems

- Gas conditioning and cooling

- Kilns

- Preheaters

Sampling, preparation and analysis

- Automated laboratories

- Sample analysis

- Sample preparation

- Sampling and sample transport

- Laboratory software and quality optimisation

Ventomatic® Storage and dispatch

- Empty bag handling and storage

- Filling units

- Palletising

- Truck and wagon loading

- Silos

- Services

Maintain

- Audits and inspections

- Condition monitoring

- Maintenance

- Operational services

- Remote Services

Optimize

- Operational services

Services by technology

- Crusher maintenance services

- Milling and gear services

- Packing and dispatching equipment services

- PFISTER® Feeding and dosing services

- Pneumatic conveying services

- Pyro services

- Automation services

- Solutions

- Company

- Products

Products

CrushingEmission controlGas analysis and emissions monitoringMilling and grindingPFISTER® Feeding and dosingPneumatic conveyingProcess control and optimisationPyroprocessingSampling, preparation and analysisVentomatic® Storage and dispatchBrochures

Download library - Services

- Solutions

Solutions

- Alternative fuels

- Calcined Clay

- Carbon Capture in Cement

- Emissions Compliance

- Industry 4.0 – Digital Solutions

- Supplementary Cementitious Materials

Research and Development

- Company

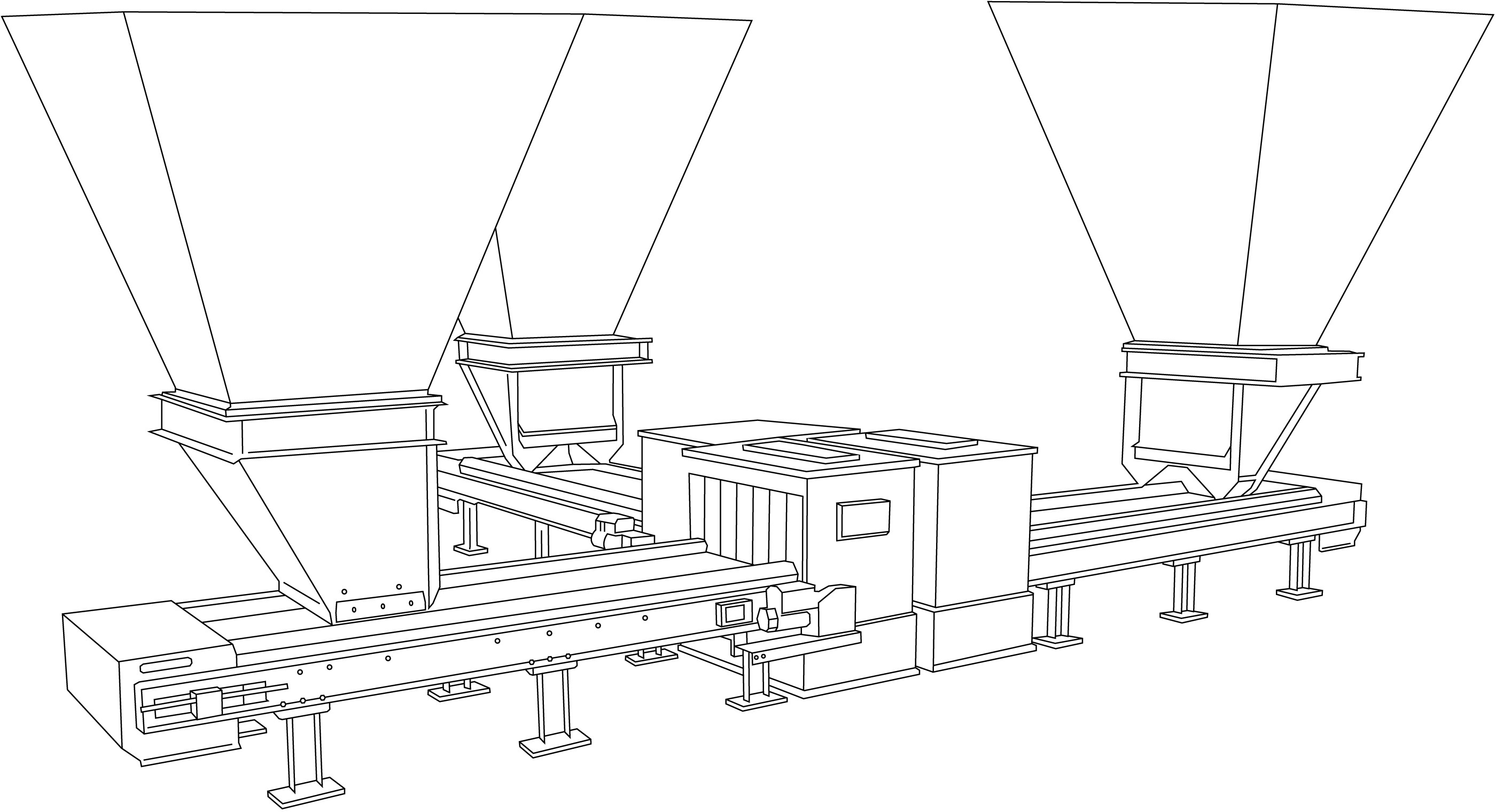

PFISTER® belt weighfeeders

Every part of a manufacturing line relies on accuracy, consistency and reliability to deliver optimum productivity. That’s why we use continuous gravimetric dosing in PFISTER® belt weighfeeders. Accurate dosing on a robust linear system available in a range of lengths, widths and capacities to suit your application.

products

WHAT WE OFFER

Continuous gravimetric dosing of fine, coarse and stick materials

Our PFISTER® belt weighfeeders are robust enough to reliably handle a range of materials: sticky, fine or coarse. The gravimetric weighing technology is the same as you will find on our proven PFISTER® rotor weighfeeders, and so is the high quality equipment and the easy operation. The main difference is the layout. This is a linear system, where weighing takes place on the belt.

.png?w=3840&q=80&auto=format)