Quality control solutions you can trust

At every stage in the cement process, you are continuously making decisions that impact final product quality, your plant’s productivity and ultimately, profitability. Good decisions rely on high-quality data, so you need sampling, preparation and analysis systems you can trust.

Reliable data is key to a smoother running cement plant

Sampling, sample preparation and analysis are key to the smooth running of your cement plant. Without reliable data, you risk kiln stability, high energy consumption and poor product quality. That’s why so many cement plants around the world trust us with their quality control chain.

We have got every part of the process covered – from the quarry to the cement silos, ensuring safe, fast and accurate laboratory analysis. Around the world, 150+ automated laboratory systems, 200+ automated sample transport systems, and 700+ advanced quality control applications are currently installed in the cement industry. We are proud to be the technology leaders.

Acquiring trusted equipment brands such as Autec and Pfaff has deepened our sampling, preparation and analysis experience and capabilities. Our solutions include:

- Automated sampling and sample transport

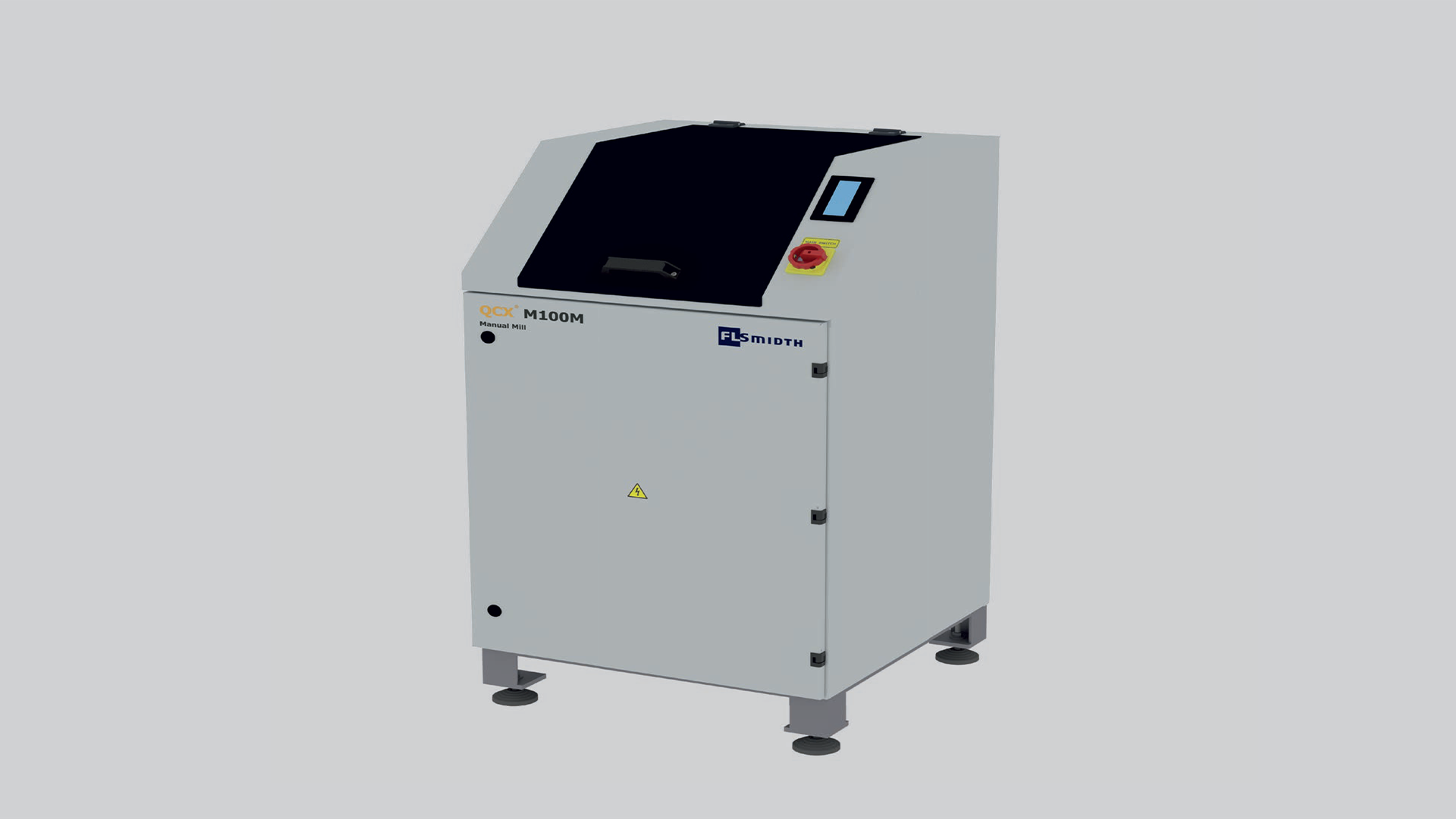

- Manual and automatic sample presses

- Combined mill and press

- Sample fusion

- Automatic analysers

- Complete laboratory solutions

Automated sampling and sample preparation for cement plants

Our sampling, sample transport and laboratory equipment supports you to better control your cement plant production systems. You can achieve fast, accurate and reliable laboratory results, resulting in improved quality, productivity and safety. Solutions can be scaled to suit your needs – from standalone to fully-automated cement laboratory preparation.

Advanced quality control solutions for cement production

Higher profitability, increased efficiencies and production stability are driven by advanced quality control. Our systems ensure that cement plants deliver superior, more consistent cement quality, with cost-efficient additive control and reduced fuel consumption. They also eliminate the need for specific sampling and analysis of raw materials into feeders.