Accurate and reliable dosing of alternative fuels and biomass

What we offer

True fuel flexibility: a multi-fuel rotor weighfeeder you can rely on

Introducing alternative fuels can be daunting. How will it affect your process? Which fuels are available to you? How will the local community respond? To help you answer these questions in an affordable way, we’ve developed the PFISTER® AF Starter Kit, a Plug and Play solution that allows you to ‘test drive’ alternative fuels.

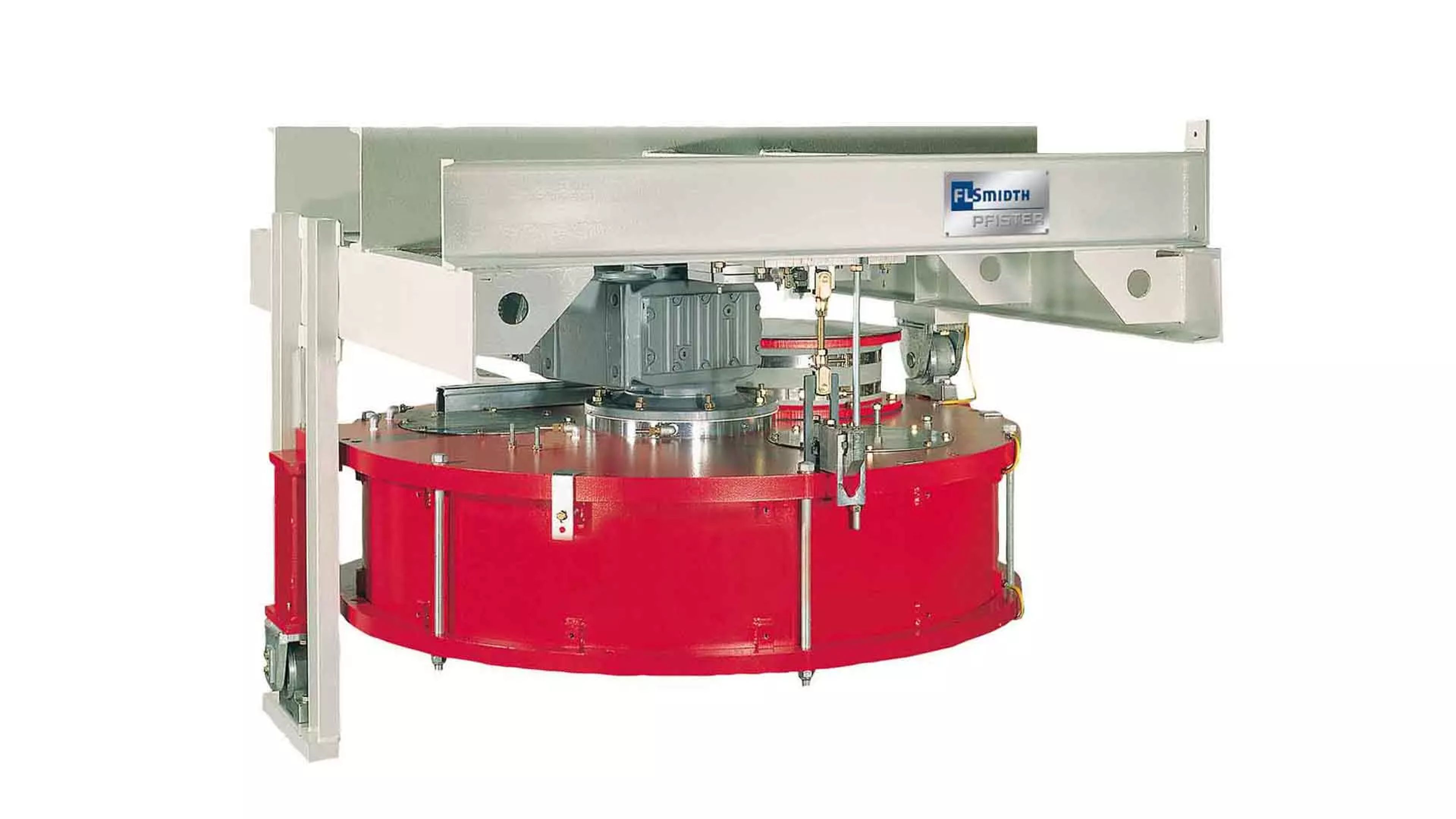

Safe. Clean. Efficient. Flexible. Reliable. The PFISTER® TRW-S/D

Alternative fuels are the green choice – but they can still be damaging to the environment if not properly managed. Feed systems should be absolutely dust and air-tight to avoid any of the feed escaping to the surroundings and to prevent dust and odour emissions. ThePFISTER® TRW-S/D rotor weighfeeder is completed enclosed and dust-free. Safer. Cleaner.

Minimal maintenance

We know that continuous operation is best for your kiln. That’s why we keep maintenance to a minimum. All machine parts in contact with material are made from steel, so wear is negligible. Moving parts are minimised, and there’s just one rotating part: the rotor wheel itself. As an enclosed system, it’s not exposed to dust from outside – in fact, the centre bearing is purge air-sealed to eliminate dust penetration, so even with dusty materials very little cleaning is needed. And for the little maintenance that is needed, access is available from outside the equipment so maintenance stops are quick, easy and safe.

Fuel homogenisation in the prehopper

The PFISTER® TRW-S/D includes a pre-feeder hopper with stirrer arm above the rotor weighfeeder. This provides several advantages: It homogenises the material to give a more consistent fuel quality; It ensures the steady loading of the rotor weighfeeder, even if there is a brief interruption in supply; When equipped with load cells, it enables periodic online calibration of the weighfeeder, which enables a comparison of the static load and the continuous weighing result from the rotor weighfeeder.

Multi-fuel system

One of the major issues when dealing with solid alternative fuels is finding a reliable supplier. Most likely, the source – and therefore the material characteristics – will change. FLSmidth has experience in nearly all kinds of materials. Variations in density and size are accounted for by the gravimetric feeding system. And because of the large amount of weighed material in the system, it is possible to feed fuels with a very low density. The PFISTER® TRW-S/D is designed to handle fuel material densities from 0.05 t/m³ to 0.7 t/m³ with the same machine, giving you maximum flexibility.

High feeding accuracy

Stable kiln operation and complete combustion – that’s what you want to achieve with your alternative fuels. And for us, that means dosing with high accuracy and consistency. The PFISTER® TRW-S/D doses with the highest accuracy, guaranteeing a maximum deviation in the actual and set feed rate of ±1.0%. Very light materials such as plastic could be difficult to measure because of their very low gravimetric force. We solve for this by ensuring high bulk loads. PFISTER® rotor weighfeeders can measure a material layer of up to 500 mm in the feeder without the risk of material spilling. This relatively large mass of bulk material leads to a high momentary load in the measuring section of the feeder.

Explosion-proof

To keep you safe and comply with local regulations, PFISTER® rotor weighfeeders can be designed to be explosion-proof for up to 10 bars pressure overload. Pfister® TRW-D is approved according to EC-type examination.

Gravimetric feeding with advanced weighing electronics

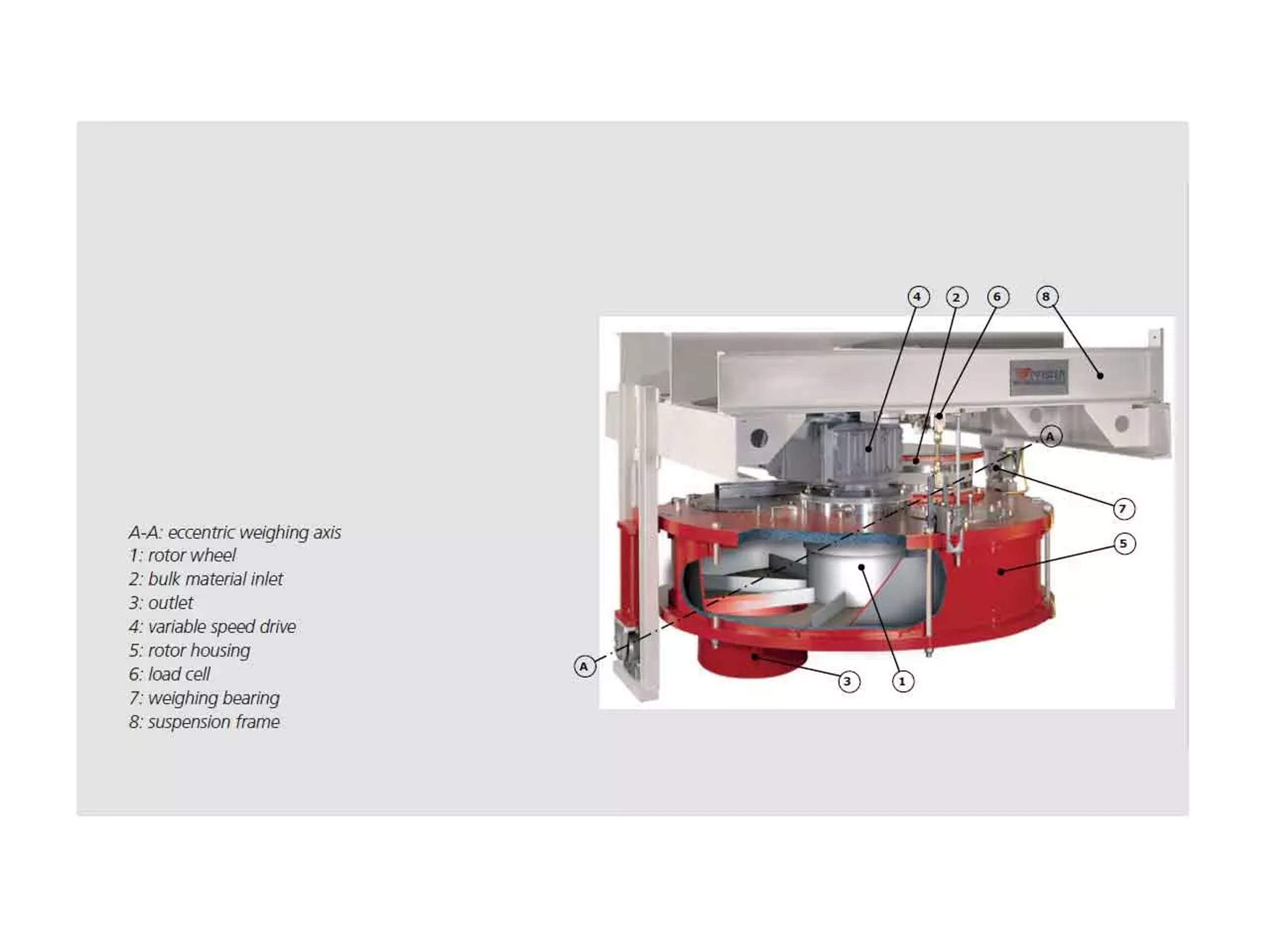

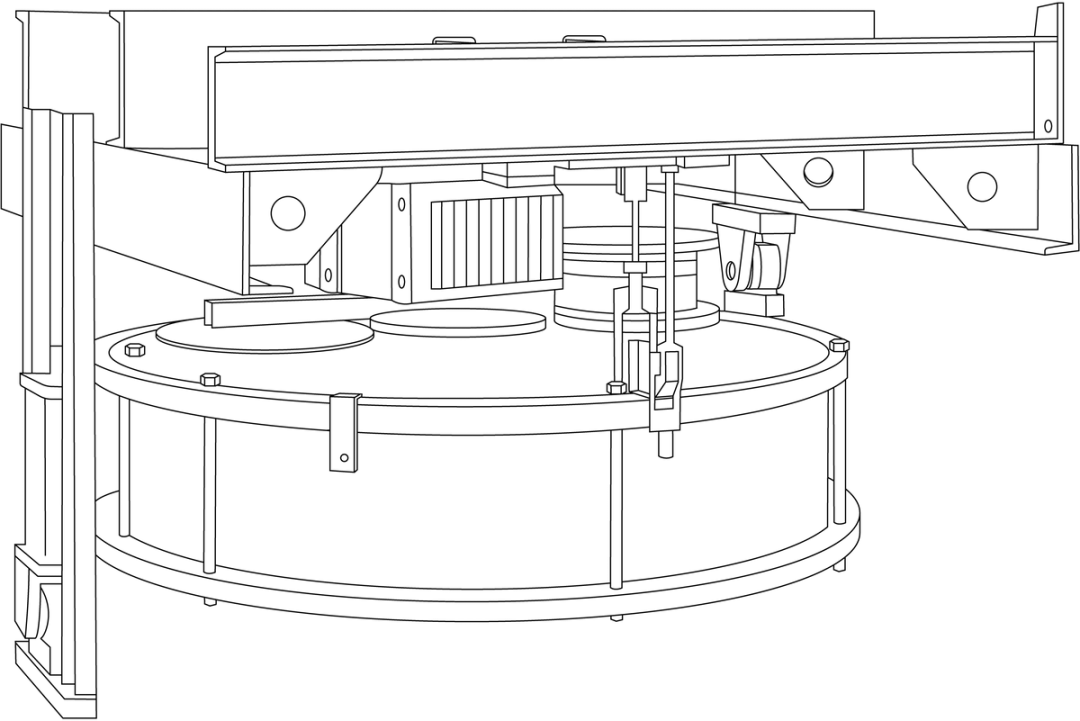

The PFISTER® TRW-S/D is especially designed for dosing alternative fuels. But all PFISTER® rotor weighfeeders operate on the same weighing and dosing principle, illustrated in the picture below.

Weighing and dosing principle

Material is extracted from the storage unit and is transported in the rotor chambers (1) from the inlet (2) to the outlet (3). The rotor is mounted on bearings that form a weighing axis (A-A) eccentric to the rotor shaft and through the middle of inlet. The third point is suspended at a load cell (6), which weighs the content in the rotor wheel gravimetrically. The measured gravimetric force indicates the mass of the bulk material in the rotor weighfeeder prior to material discharge from the outlet (3). This information is stored together with the relative rotor wheel position and used by the advanced weighing electronics to calculate the optimum rotor wheel speed to provide consistent and highly accurate feed to the burner. The more material in the rotor, the slower the speed. The less material, the higher the speed. These advanced weighing electronics use ProsCon® prospective control to react almost instantly to changes in the feed make-up that would otherwise affect dosing accuracy. It’s a proactive approach to dealing with variable feed materials such as alternative fuels and is particularly effective in this multifuel rotor weighfeeder.