Our vertical roller mill offers optimum raw, cement and slag grinding

_Raw_and_Cement_Mill.png?w=1080&q=80&auto=format)

What we offer

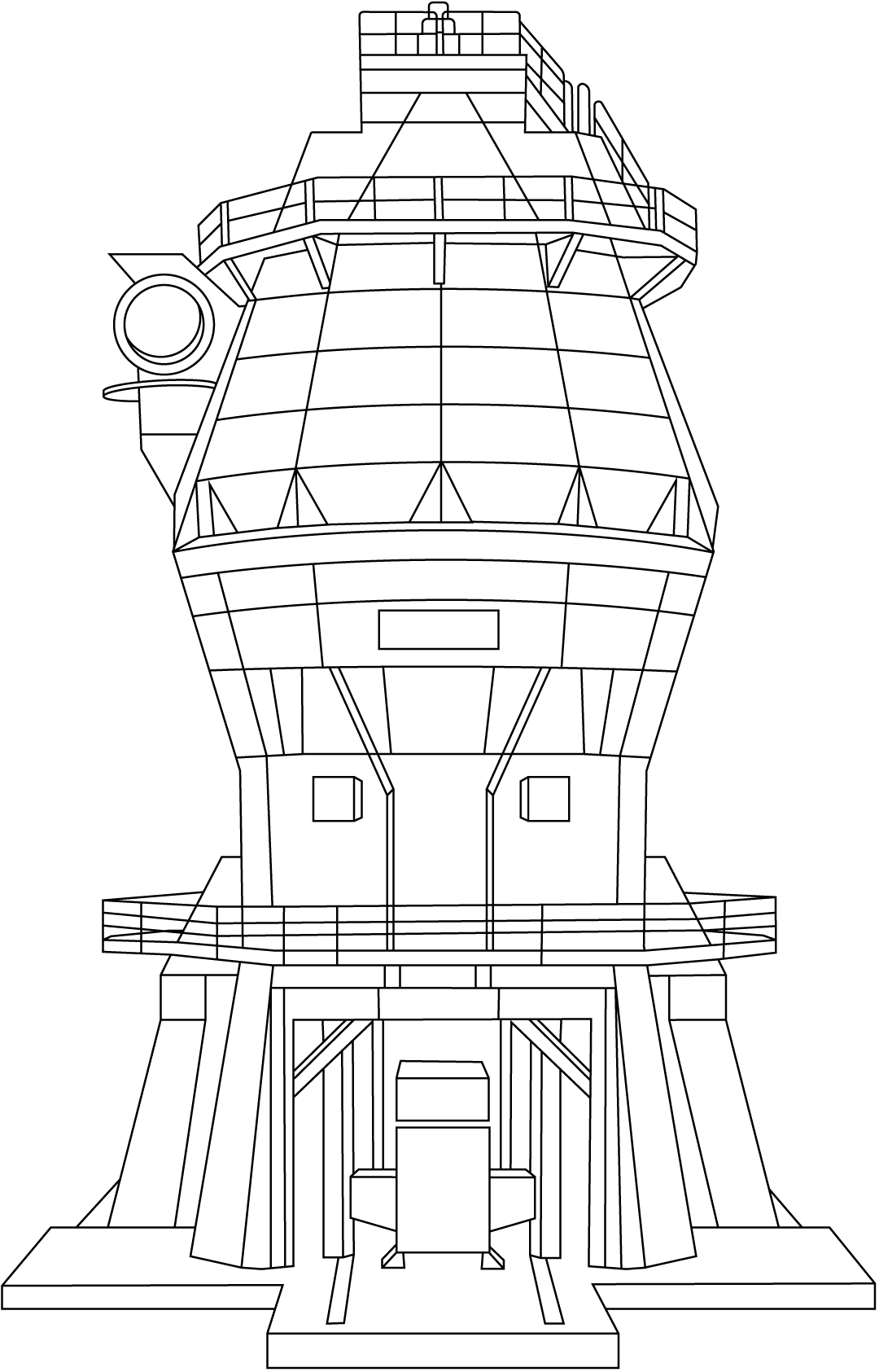

Vertical roller mill with peak raw, cement and slag grinding performance

Our cost-saving Vertical Roller Mill (VRM) exhibits a modern design approach. We continuously improve our solution with the latest updates to enhance grinding performance and overall productivity. The success of the OK™ Mill highlights the reliability of its technology and a contribution to the cement industry amidst rapidly emerging trends of greater variation in feed materials and larger production capacity. Our OK Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to its highly effective drying performance, the OK Mill is the natural choice for grinding blended cements with one or more wet components. A design for optimal efficiency ensures your operating costs are minimised while profitability is maximised.

Impressive energy savings in operations

Our OK Mill with its patented roller and table design delivers the best power efficiency of any cement vertical roller mill. It uses five to ten percent less power than other vertical roller mills. In addition to efficiency, the unique design also makes the vertical roller mill more stable in operation than other vertical roller mills, offering higher availability and the capability to grind the finest products and highest Blaine cement.

Intelligent design simplifies operations and maintenance

With a modular design, the OK Mill offers the best possibility for low long-term total cost of ownership (TCO) and minimal spare parts net working capital. Parts commonality leads to greater flexibility in sharing spare parts across vertical roller mills, regardless of size and application. It also simplifies spare parts inventory, saving you costs and improving parts delivery times.

The segmented wear parts can be maintained inside the mill or if needed, the rollers can be removed from the mill using the swing out feature for external maintenance. The roller wear parts are made of the toughest material that is suitable for repeated hard-facing.

Compact layout makes installation hassle free

The OK Mill combines the drying, grinding, material conveying and separation processes into one compact unit, requiring fewer machines in the mill circuit and therefore, simplifying plant layout. Concrete mill stands replace the traditional steel structures, reducing installation time and costs. Using concrete also means lower mill vibration at the foundation.

The high-performing vertical roller mill generates minimal noise during operation due to the lower level of mill vibration. This makes installation without a building feasible. This substantially reduces civil construction costs and improves the working environment for your plant employees.

Reliable vertical roller mill for easy grinding of raw, cement and slag

Consistent and reliable production

Our OK Mill offers a high run factor of typically 90 to 95 percent availability. And because the OK Mill can continue to operate with a reduced number of rollers, you can achieve 60 to 70 percent of nominal output in emergency or low demand times.

Lowest total cost of ownership

Selecting a single large vertical roller mill size gives you lower total cost of ownership per tonne of cement produced. Common parts increase equipment availability, lower maintenance and parts inventory costs and help keep the machine in operation while parts are being repaired.

Maximum energy efficiency

The industry best in energy-efficient grinding, the OK Mill uses five to ten percent less power than other vertical roller mills and 30 to 50 percent less energy than conventional ball mills.

Easy operation and maintenance

Worn roller grinding surfaces can either be replaced or re-welded inside the vertical roller mill. If needed, the roller swing-out feature allows easy removal of rollers to perform maintenance work externally. Sharing of common parts is possible across different vertical roller mill sizes for both cement and raw applications. This offers you more opportunities in the use of standard component combinations, along with maximal spare part flexibility and reduced spare parts inventory.

Operating flexibility

With the OK Mill, easy switching between different cement types is possible, along with adjustment of particle size distribution (PSD) to match or to improve products made in existing mills.

Smart vertical roller mill design for raw, cement and slag grinding

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application. Equipment longevity is assured with durable wear protection on all internal surfaces. The main difference between cement and raw OK™ Mills lies in the roller grinding profiles, with the raw mill rollers bearing a spherical shape that is more suitable for grinding cement raw materials.

Making a stand against high civil construction costs

We have replaced the conventional steel stand with a simplified concrete stand for the OK™ Mill. This allows standardisation of the mill’s mechanical parts, along with the use of the same construction procedure. Replacing the steel with concrete also minimises vibration in the foundation. A simple layout with fewer machines in the mill circuit and eliminating the need to transport steel stand parts helps keep civil construction costs low.

Rolling with efficiency – and longer lasting too

The OK™ Mill’s patented roller and table design uses a swing lever and roller assembly. This enables easy roller removal for maintenance and replacement. The rollers are made with the toughest material, offering increased longevity and efficient raw and cement grinding. This vertical roller mill uses a hydro-pneumatic system to press its grinding rollers against the material bed on the rotating grinding table.

Complete size range to fit your grinding needs

The OK™ Mill is offered in a complete size range, including 3-, 4- and 6-roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts. This ensures the ability to meet all possible capacity requirements in a single vertical roller mill solution. Reliable large-sized mills help reduce the project CAPEX investment and the total cost of ownership per tonne of cement produced, while increasing total plant productivity.

downloads

Brochures

First-time service agreements for OK Mill and key OK Mill components

20.08.2025 |

1.07 MB |

English