Coal mill gas analysis is a must-have safety measure

What we offer

Silo/filter probes for your coal mill system

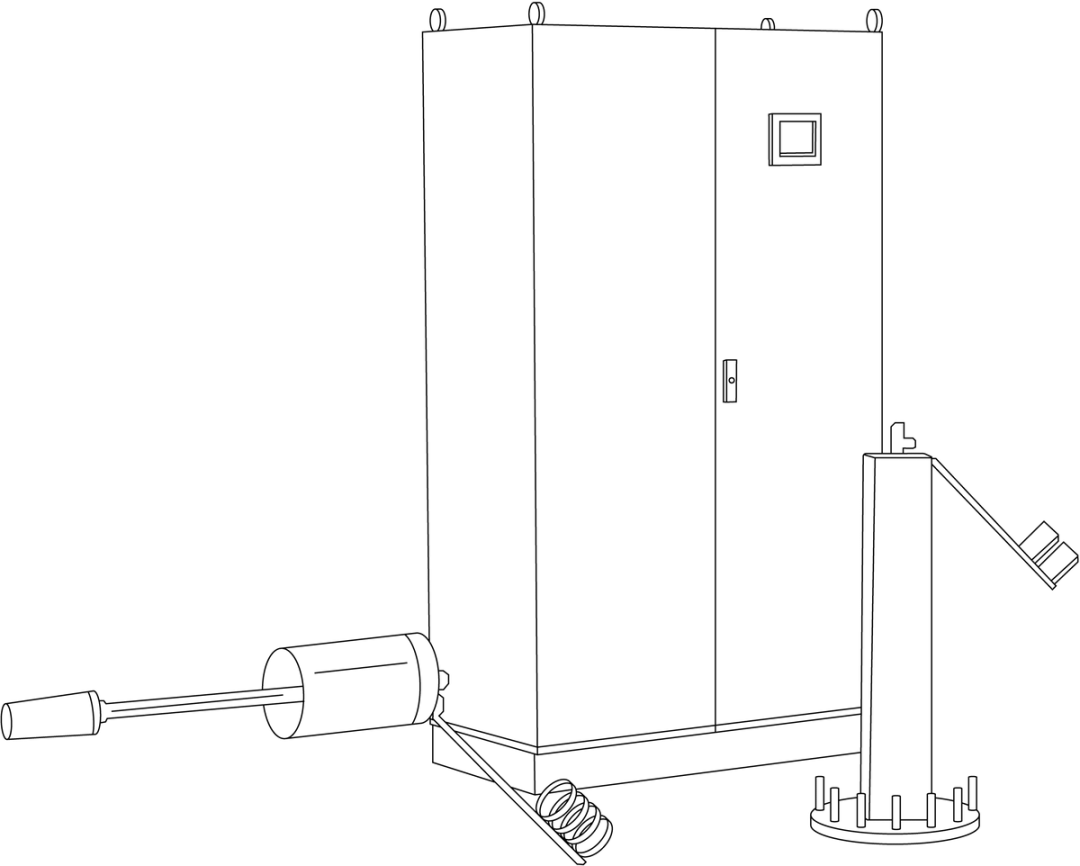

Highly combustible coal dust poses a serious hazard. CO builds up in coal-filled silos and in cyclones or bag houses that are not being used, while imprecise O2 levels in inert coal mills can also present a significant danger. In either situation, self-ignition is a real possibility. Fire can spread quickly, causing extensive damage and putting people at risk. This risk can be avoided, though. Monitoring these gases using silo/filter probes attached to a coal mill gas analysis system enables operators to detect potentially dangerous conditions and address them before the worst happens. Our Single Dry Filter Probe (SDFP) and Single Dry Silo Probe (SDSP) can be used individually or in combination for single point or multi-scan analysis. The coal mill gas analysis system comprises SDFP and/or SDSP, sample lines and gas conditioning system, and works with the GASloq 1200 or GASloq CUBE.

Feel more secure with coal mill gas analysis

Your coal mill system is a high-risk area of your plant. Inert coal dust is particularly vulnerable to self-ignition, with potentially catastrophic consequences. Monitoring the levels of toxic and explosive gases in your coal mill, coal silo and filter/baghouse allows operators to act before conditions become dangerous. The benefits are clear: equipment and personnel are safer. You don’t lose valuable production time for repairs. You sleep better knowing you have total control of your system.

Simple. Effective. Low-maintenance.

The SDFP and SDSP are designed for easy operation. The extractive probe continually draws gas samples out for analysis, giving you real-time results that enable you to make real-life decisions. The modular design makes for easy installation and maintenance. And it is flexible to your needs, whether you choose the single point or multi-scan analysis option.

Silo probe. Filter probe. Single point. Multi-Scan. What do you need?

Our coal mill gas analysis system is designed to fit to your requirements. All components of this modular system are high quality to guarantee long life and optimum performance, even under aggressive process conditions.

CO measurement

Large quantities of stationary coal or coal dust are vulnerable to self-ignition. Coal-filled silos, or de-dusting cyclones or bag filters that are not in operation. These are the circumstances where CO monitoring is crucial. When a silo is empty, or the filter or de-dusting cyclone is in operation, the risk is minimal, but for the rest of the time a gas analysis system is required.

O2 measurement

O2 levels should be monitored in an inert operated coal mill. Low-oxygen process gas is used as flow media in the mill to prevent the coal from igniting. But those oxygen levels need to be checked continuously to be sure they are right.

Single point analysis

The single point analysis system consists of a SDFP or a SDSP, a sample line and a GASloq 600 gas conditioning system. Single point analysis is well-suited to silos that are physically isolated from other silos. It is a cost-effective option because it is built specifically for the task at hand, so the HMI, PLC and other elements not needed for this type of measurement are not included.

Multi-scan analysis

The coal mill multi-scan analysis system includes SDFP and SDSP, sample lines and a gas conditioning system. The number and type of probes is dependant on the desired number of measuring points, and can be tailored to your needs. This is a cost-effective measurement solution as it can carry out all the desired coal mill gas analysis from one system, rather than installing several different analysis instruments. Continuous analysis in one inert operated sample point of the multi scan system is possible by adding extra hardware to the analyser system. The system is then built with a parallel conditioning line so that it is possible to measure O2 continuously in one point and at the same time to measure CO switching between the other sampling points. This measurement is used for measuring continuous O2 after the coal mill filter.

How it works

In both the SDSP and the SDFP, a sample of the gas is continuously being drawn out from the process by a probe and through a sample line into the conditioning system. The gas conditioning system removes all dust and dries the gas and any contaminating components. The gas is then delivered to the analysers with a fixed reference of dew point, flow, pressure and temperature in order to establish correct analytical correlation with any data taken at any other time. Fire fighting CO2 equipment can be controlled from this system.