article

Early installation of ECS/ProcessExpert® V9.1 (PXP) delivers benefits

Officially launched in July 2024, the latest update to our ECS/ProcessExpert (PXP) advanced process control solution brings together cutting-edge technologies to deliver real-world results. Early adopter CEMEX is already reaping the benefits.

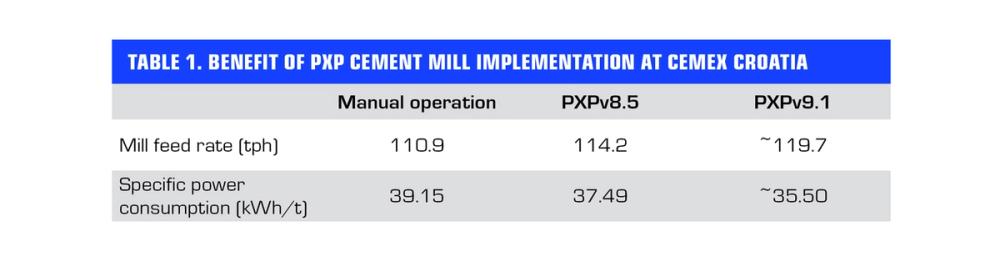

CEMEX implemented PXP v9.1 on a 110 tph cement mill at a plant in Croatia. The plant had been running PXPv8.5 on the mill, resulting in a 3% increase in mill feed rate and a 4.3% lower specific power consumption compared to manual operation. According to the cement producer, PXPv9.1 has delivered an additional 3% to 4% improvement in both key performance indicators over v8.5. This brings the cumulative benefits of PXP implementation to 7% to 8% higher mill feed rate and similar lower specific power consumption over manual operation.

The v9.1 update includes several new features, including a new self-adaptive controller that enhances responsiveness to changing process dynamics. “The new controller is reliable, delivering a stable process and maintaining product quality in terms of fineness and Blaine,” reported CEMEX.

CEMEX Cement Plant, Croatia

In addition to the new controller, PXP v9.1 features a Cloud-based PXP Insights modules. The module allows enterprise-level benchmarking of plant/equipment performance, including dedicated sustainability dashboards that provide global visibility of the CO2 savings achieved when using the software.

Meanwhile, control-loop performance monitoring identifies underperforming control loops and diagnoses problems for correction, ensuring precise and efficient control of the main process parameters.

“We are extremely pleased with the results seen at CEMEX, which demonstrate the significant benefits achievable by PXPv9.1 even at plants running PXPv8,” said Dinesh Sampath, Global Product Manager for Process optimization at FLSmidth Cement. “These benefits are compounded when updating earlier versions of the software or when switching from manual control.”

ECS/ProcessExpert v9.1 marks a “generational advance in advanced process control for the cement industry,” concluded Dinesh. “Enhancing process stability, productivity, and disruption response offers powerful support to the industry as it tackles rising production costs, enhanced competition, and the need to reduce emissions and environmental footprint.”

This latest update to our ECS/ProcessExpert (PXP) advanced process control solution was officially launched in July 2024, read the announcement here including a webinar by Dinesh Sampath.

.jpg?w=3840&q=80&auto=format)